Cable terminal with stress pipe

A technology of cable termination and stress tube, applied in the direction of cable termination, etc., can solve the problems of uneven distribution of electric field, affecting the safety of transmission lines, electric stress concentration, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

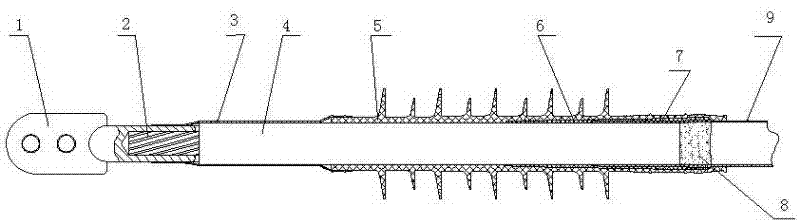

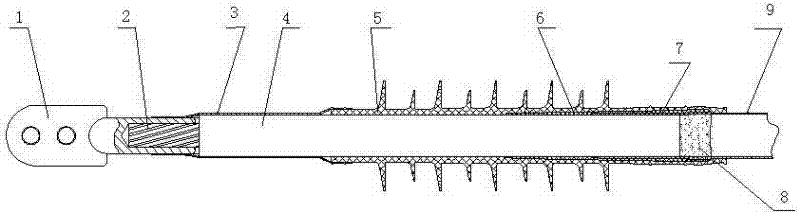

[0017] As shown in the figure, the structure of the cable terminal with a stress tube of the present invention includes a cable and a silicone rubber cable terminal sleeve 5 . The cable radially includes a core 2, an insulating layer 4, an outer shield 8 and an outer sheath 9 sequentially from the inside to the outside, and they are coaxially sleeved together. The end of the cable is stripped to a certain size in turn, and the stripped lengths of each layer structure of the cable are different. The stripped lengths from high to low are outer sheath 9, outer shield 8, insulating layer 4 and Core 2. In the axial direction of the cable, the end of the core 2 protrudes to the outermost side, followed by the end of the insulating layer 4 , the end of the outer shield 8 and the end of the outer sheath 9 . The outer peripheral surface of the silicone rubber cable terminal sleeve 5 is provided with several annular sheds arranged side by side, and these sheds and the silicone rubber c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com