Contact pin movement mechanism for thermistor material strips

A thermistor and moving mechanism technology, applied in the direction of resistors with negative temperature coefficient, resistors with positive temperature coefficient, etc., can solve the problems of unable to continue to move, the material belt is stuck, etc., to improve work efficiency, overcome the overlapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

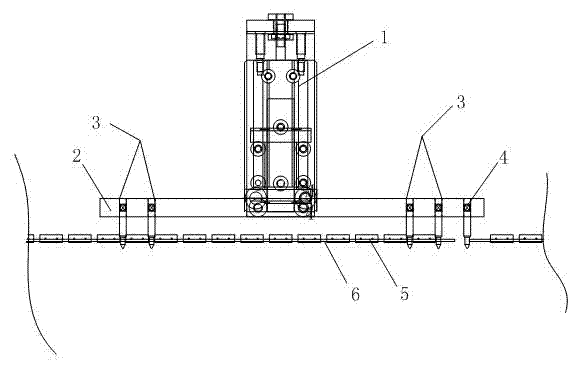

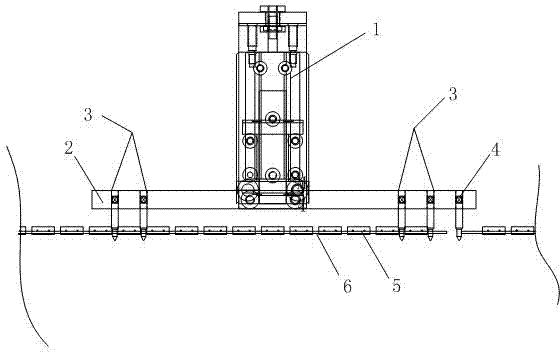

[0009] Such as figure 1 As shown, the thermistor material has a pin moving mechanism, and a pin fixing plate 2 is suspended on the lower end of the pin moving mechanism 1 through rollers, and the two tail ends of the pin fixing plate 2 are respectively fixed with first pins at equal intervals. Pin 3 is provided with a thermistor strip 5 at the lower end of the pin fixing plate 2, the thermistor strip 5 is segmented, and each section of thermistor strip 5 is provided with a plurality of process holes 6, each The distance between the process holes 6 is equal to the distance between the first pins 3 at intervals, and the second pin 4 is fixed on one end of the pin fixing plate 2, the second pin 4 and the first pin 3 The distance between them is equal to the distance between the first pins 3 , and the second pins 4 are located between the end of the previous thermistor strip 5 and the head end of the next thermistor strip 5 .

[0010] In specific applications, after the pin movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com