Hub frame hub tyre

A technology of tires and hubs, applied in the field of hub bone and hub tires, to achieve the effect of reducing car crashes and fatalities, and reducing the degree of overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

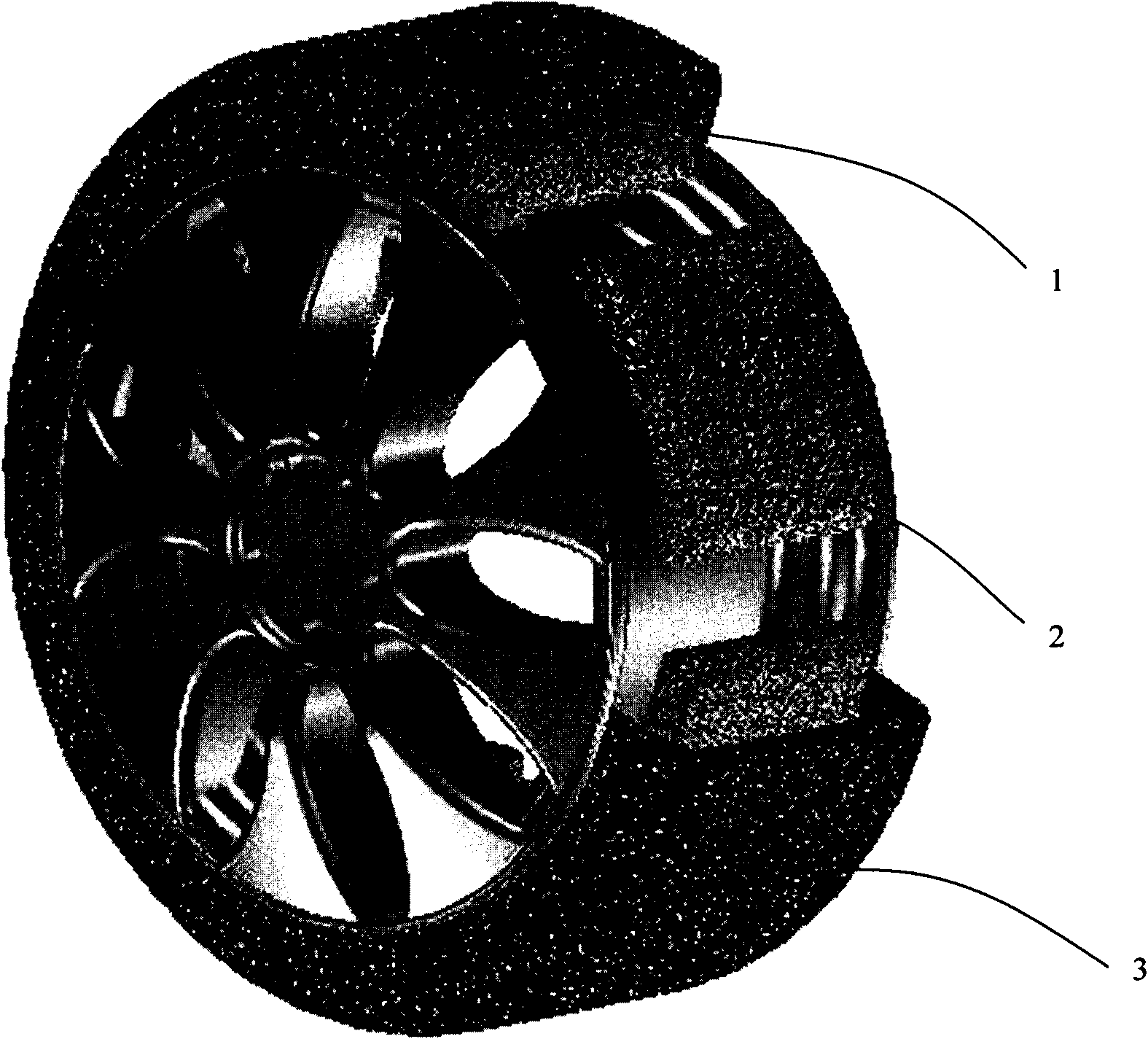

[0018] 1. The design strength of the tire hub, the mounting part of the hub and the overall design strength of the hub of the present invention is to ensure the impact load suffered by the tire in the case of a sudden puncture.

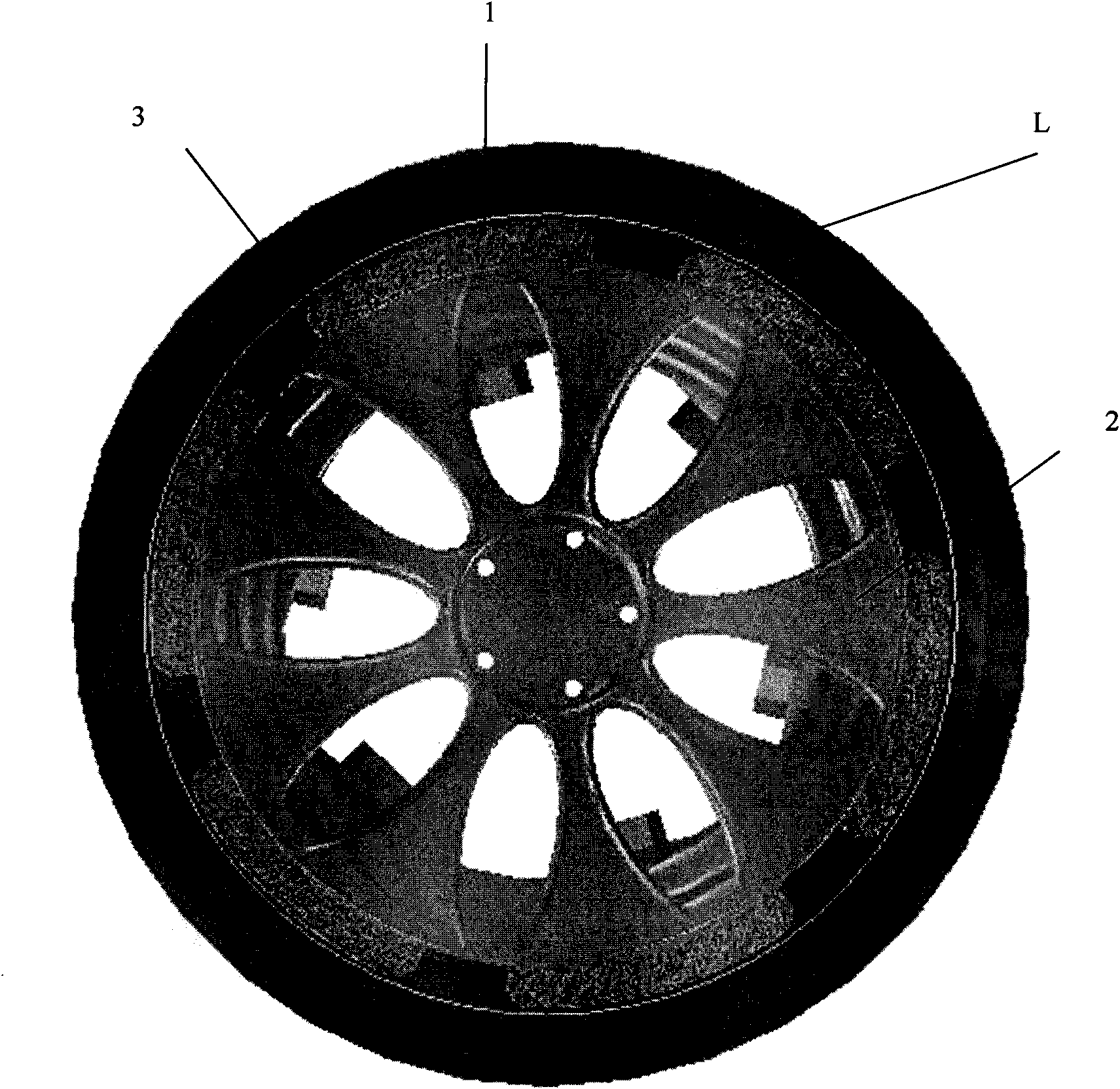

[0019] 2. The tire hub bones of the present invention should consider the overall dynamic balance of the tire in the design, layout and quantity, and the production weight and size of each hub bone mounting part and the hub bone should be as theoretically equal as possible.

[0020] 3. figure 2 The circular arc formed by the force-bearing circular arc portion L of the hub bone wheel shown in the front view of the present invention is shown as a continuous, full-circle curve without ups and downs.

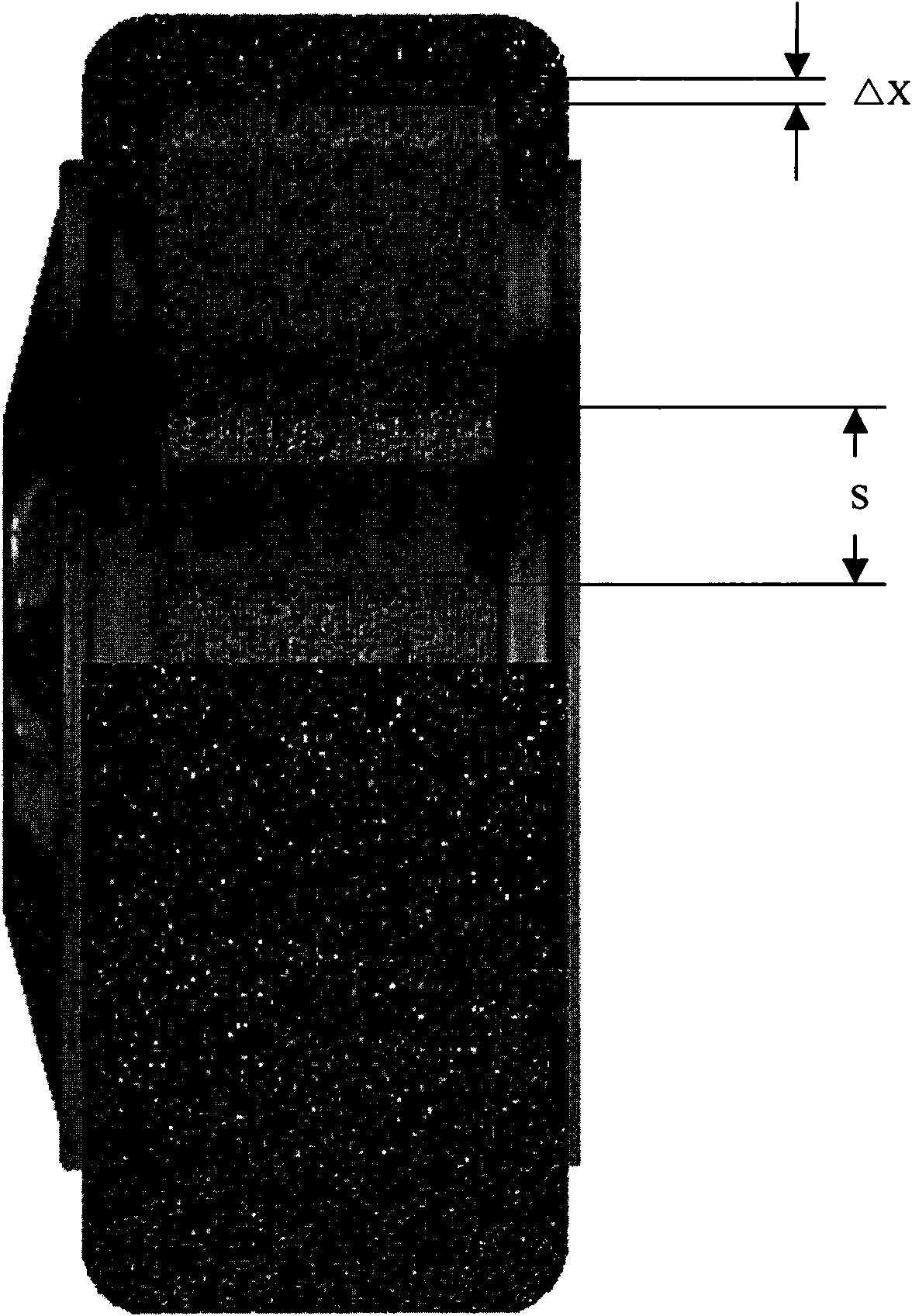

[0021] 4. Figure 5 The shown hub bone is inserted into the hub bone mounting part of the hub, and the state of the hub bone head being inserted into the hub bone cavity is the minimum distance between each hub bone.

[0022] 5. image 3 The shown distance S b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com