Carriage for coal conveying train

A train and coal technology, applied in the field of train carriages, can solve problems such as driving safety hazards, polluting the environment, and reduced visibility of train tracks, achieving the effects of reducing pollution and avoiding driving safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

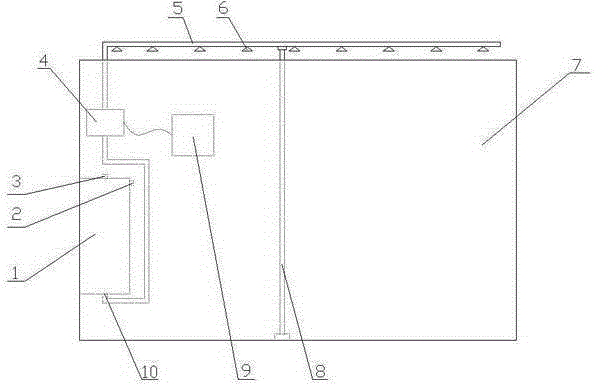

[0012] Such as figure 1 As shown, the train carriage for transporting coal of the present invention includes a box body 7, and the top of the box body 7 is in an open shape. A liquid storage tank 1 is arranged on the inner side wall of the box body 7 , a liquid outlet 10 is arranged at the bottom of the liquid storage tank 1 , a liquid inlet 2 is arranged on the top of the side wall, and an exhaust port 3 is arranged at the top. The liquid outlet 10 of the liquid storage tank 1 is connected with a spray main pipe 5 through a water pipe, and a water pump 4 is arranged on the water pipe. Described spray main pipe 5 is arranged horizontally, and is positioned at the top of casing 7 openings, and spray main pipe 5 is uniformly arranged with nozzle 6 along its longitudinal direction, and the inner cavity of nozzle 6 all communicates with the inner chamber of spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com