Method for extracting and purifying tangerine polymethoxyflavone

A technique of polymethoxylated flavonoids and a purification method, which is applied in the field of extraction and purification of active ingredients of agricultural by-products, can solve the problems of difficult industrialization, expensive purification equipment, complicated processes, etc., and achieves easy industrial production and simple and easy purification process , the effect of low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: (extraction and purification method 1 of citrus polymethoxylated flavone crude extract)

[0036] (1) Extraction of citrus polymethoxylated flavonoids:

[0037] 1) Pretreatment of citrus peels: dry the citrus peels to a water content of ≤5%, grind them through a 30-mesh sieve, and set aside;

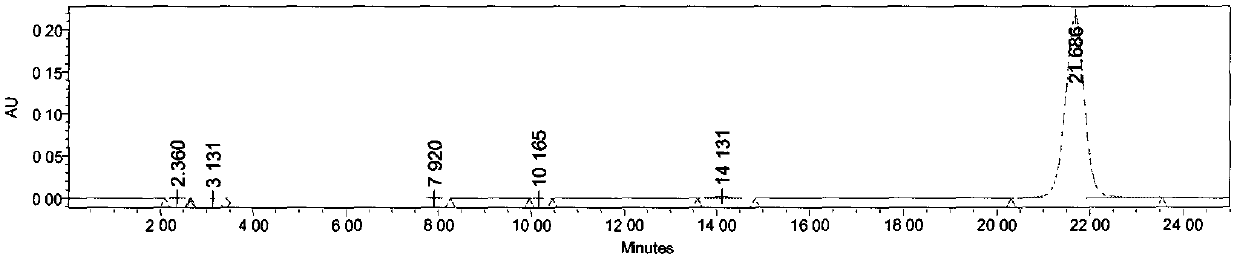

[0038] 2) Crude extraction and extraction of citrus polymethoxylated flavonoids: mix 500g of citrus peel powder and 5.0L of water, heat to 100°C for extraction for 1 hour, and filter to obtain a water extract; mix the water extract with n-hexane by volume Mixing and extracting at a ratio of 1:0.5; the extract was evaporated to dryness under reduced pressure at 40°C to obtain a crude extract of citrus polymethoxyflavones; through HPLC analysis, the crude extract contained 30.8% nobiletin, orange Cortex 22.7%;

[0039] (2) column chromatography purification of citrus polymethoxyflavone crude extract;

[0040] 1) Preparation of the crude extract solution: Dissolve 5 g...

Embodiment 2

[0044] Embodiment 2: (extraction and purification method 2 of citrus polymethoxylated flavone crude extract)

[0045] In this example, step (2) column chromatography purification of the crude extract of citrus polymethoxylated flavones;

[0046] 1) Preparation of the crude extract solution: Dissolving 5 g of the citrus polymethoxylated flavone crude extract in 500 ml of 30% ethanol solution;

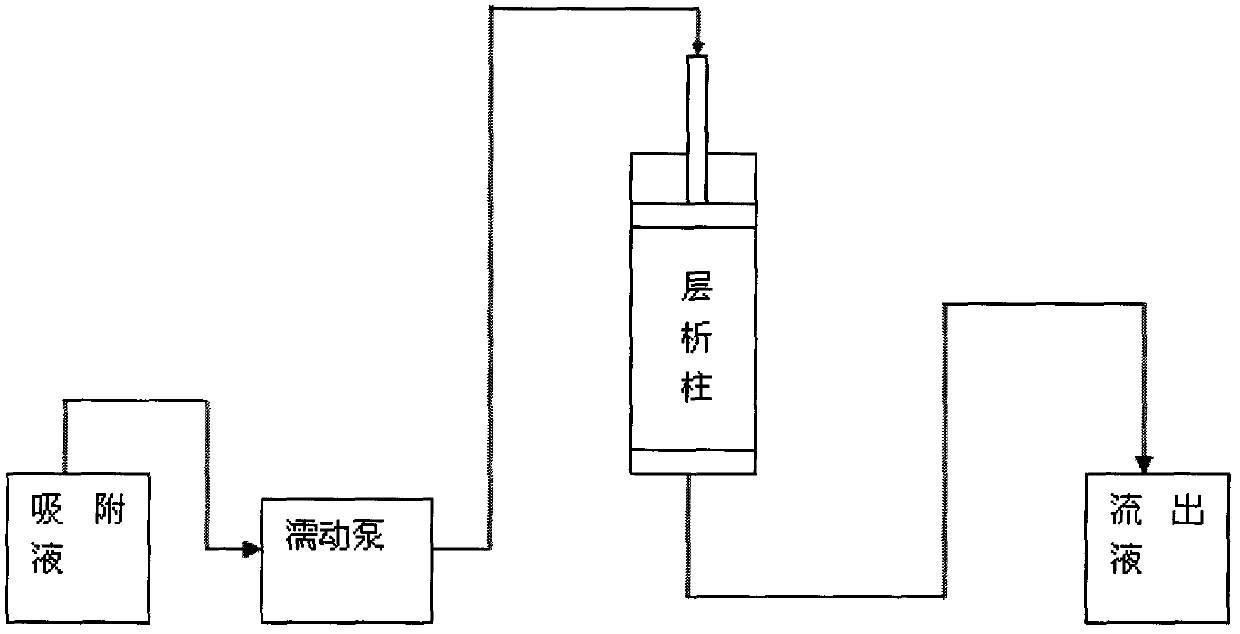

[0047] 2) Packing of macroporous resin column: put the pretreated macroporous resin DM312 into the chromatography column to a column height of 20cm;

[0048]3) Adsorption of macroporous resin: 500ml of the crude extract solution was passed through the chromatographic column with a peristaltic pump at a flow rate of 1.5ml / min for 5.56h, and the effluent was collected; The total adsorption rate of the analysis column to polymethoxylated flavones is 80%;

[0049] 4) Elution, collection, concentration and drying of macroporous resin: use 500ml of 100% ethanol as the eluent; combine eluents...

Embodiment 3

[0051] Embodiment 3: (extraction and purification method 3 of citrus polymethoxylated flavone crude extract)

[0052] In this example, step (2) column chromatography purification of the crude extract of citrus polymethoxylated flavones;

[0053] 1) Preparation of the crude extract solution: Dissolve 5 g of the citrus polymethoxylated flavone crude extract in 500 ml of 40% ethanol solution;

[0054] 2) Macroporous resin packing: put the pretreated macroporous resin AB-8 into the chromatography column to a height of 15cm;

[0055] 3) Adsorption of macroporous resin: 500ml of the crude extract solution was passed through the chromatographic column with a peristaltic pump at a flow rate of 2.0ml / min for 4.17h, and the effluent was collected; The total adsorption rate of the analysis column to polymethoxylated flavones is 68%;

[0056] 4) Elution, collection, concentration and drying of macroporous resin: use 500ml of 60% ethanol as the eluent; combine the eluents from tubes 1 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com