Cement clinker and preparation method thereof

A technology for cement clinker and raw materials, applied in the direction of cement production, etc., can solve the problems affecting the economic benefits of extracting alumina from fly ash, cannot be applied, and secondary environmental pollution, and achieves saving energy consumption and reducing energy consumption. , The effect of fine grinding and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

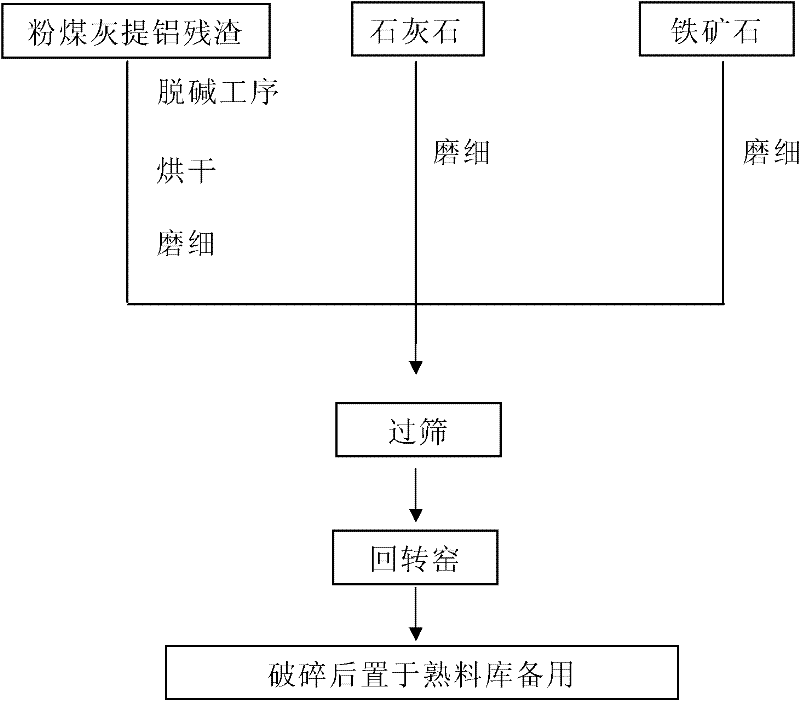

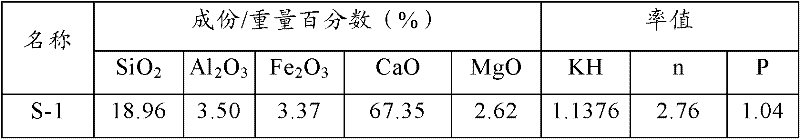

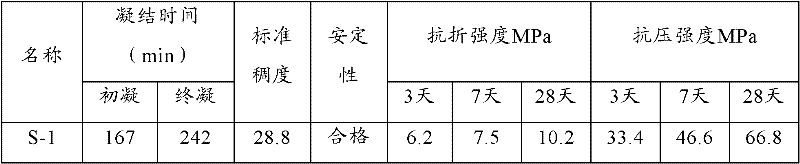

[0034] figure 1 The process flow chart of the cement clinker preparation method provided by Embodiment 1 of the present invention.

[0035] After the alumina is extracted by the soda-lime sintering method of fly ash, the main component is silicon-calcium residue, and the above residue is treated by dealkalization process to obtain the aluminum extraction residue of fly ash. The steps of the dealkalization process are as follows: (1) adding water to the aluminum extraction residue and stirring to obtain an aluminum extraction residue slurry; (2) slowly adding calcium carbide slag to the aluminum extraction residue slurry under stirring to carry out dealkalization; (3 ) filtering and washing the aluminum extraction residue slurry after the dealkalization reaction. The alkali content of fly ash aluminum extraction residue is below 0.6%, and its main chemical components are CaO and SiO 2 , the main phase of the aluminum extraction residue from fly ash is C2S (dicalcium silicate)...

Embodiment 2

[0047] Different from the embodiment, the raw material (raw meal) used in the embodiment includes: 80 parts by weight of fly ash aluminum extraction residue, 18 parts by weight of limestone, 2 parts by weight of iron ore mixed and homogenized, and the raw material after homogenization Take a small amount of material for particle size test, pass through a 100-mesh sieve, and 7.2% remains after sieving, which meets the particle size requirement of raw meal. Send the homogenized raw meal into a rotary kiln for high-temperature calcination at a temperature of 1360° C. After cooling, cement clinker S-2 is obtained.

[0048] The aluminum extraction residue from fly ash includes components in the following weight ratios: CaO: 56.71, SiO 2 : 25.36, Al 2 o 3 : 4.62, Fe 2 o 3 : 2.48, MgO: 2.03, Na 2 O+0.66K 2 O: 0.52, loss on ignition: 8.28.

[0049] The chemical composition and rate of the cement clinker S-2 prepared in this example are shown in Table 3, and the physical and mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com