Pseudomonas putida and method for producing nicotinic acid or isonicotinic acid through converting Pseudomonas putida

A technology of Pseudomonas putida and isonicotinic acid, applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problem of no reports of Pseudomonas putida, etc., and achieve high yield and good reaction conditions Mild, short-cycle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Pseudomonas putida CGMCC3830 ( Pseudomonas putida ) isolation and identification

[0036] (1) Pseudomonas putida CGMCC3830 ( Pseudomonas putida ) enrichment screening process.

[0037] Collect soil samples at 5-15 cm around the nitrile compound production plant. Take 1 g of soil sample and put it into a conical flask, add 15ml of normal saline, add glass beads, and place it on a shaker for 30 minutes. Take 0.2mL of soil suspension and spread it on the solid screening medium with 3-cyanopyridine as the only nitrogen source. The composition of the solid screening medium is: glucose 0.5%, potassium dihydrogen phosphate 0.1%, magnesium sulfate 0.01%, sulfuric acid Ferrous iron 0.002%, calcium chloride 0.002%, sodium chloride 0.1%, 3-cyanopyridine 0.1%, agar 2%, pH 7.0. Cultured at 30°C for 3 days, picked colonies of different bacteria and continued to streak and separate into single colony.

[0038] Pick 20 purified strains and transfer them to liquid m...

Embodiment 2

[0041] Embodiment 2: Pseudomonas putida CGMCC3830 ( Pseudomonas putida ) shake flask fermentation culture

[0042] Shake Flask Fermentation Medium

[0043] A: Glucose 1%, soybean peptone 0.5%, yeast powder 0.3%, malt extract 0.3%, NaCl 5%, pH 7.2.

[0044] B: Glycerin 1%, tryptone 1%, yeast powder 0.5%, NaCl 0.5%, pH 7.2.

[0045] C: Glycerin 1%, Tryptone 1%, Yeast Powder 0.5%, NaCl 0.1%, KH 2 PO 4 10.1%, pH7.2.

[0046] D: Glycerin 1%, tryptone 1%, yeast powder 0.5, NaCl 0.1%, KH 2 PO 4 10.1%, urea 1%, pH6.0.

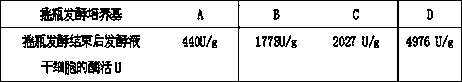

[0047] Separately pack the above-mentioned culture media, each in three parallels, and sterilize at 121°C for 20 minutes. Pseudomonas putida CGMCC3830 ( Pseudomonas putida ) were inoculated into each fermentation medium, cultured at 30° C. and 120 rpm, and the fermentation was completed in 36 hours. After the fermentation, the bacteria were collected by centrifugation at 10,000 rpm for 10 minutes, and the bacteria were washed twice with phosphate. Cells 0....

Embodiment 3

[0050] Embodiment 3: Pseudomonas putida CGMCC3830 ( Pseudomonas putida ) fermenter fermentation culture

[0051] Pseudomonas putida CGMCC3830 ( Pseudomonas putida ) was inoculated into the seed medium, cultivated at 30° C. and 120 rpm for 24 hours to obtain a seed liquid; the composition of the seed medium was as follows: 0.5% peptone, 0.5% yeast powder, 0.5% NaCl, pH 7.0.

[0052] The fermentation medium was inoculated into the fermentation medium with an inoculation amount of 1% by volume, and cultured at 30° C. for 36 hours to obtain a fermentation broth. The composition of the fermentation medium is as follows: 1% glycerol, 1% tryptone, 0.5% yeast extract, 0.1% potassium dihydrogen phosphate, 0.1% sodium chloride, and 0.1% urea. 30°C, stirring speed 150rpm-600rpm, ventilation rate 0.5-3mL / min, pH control at 7.0 with acid and alkali, after 24 hours of cultivation, collect the bacteria in the fermentation broth for reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com