Modified polyester antirust coating for construction steel bars and construction method for modified polyester antirust coating

A technology of modified polyester and anti-rust coatings, applied in the field of modified polyester anti-rust coatings for preventing steel bars from rusting on construction sites, can solve the problems of increasing the service life of buildings, low bonding force between steel bars and concrete, etc. The effect of improving the apparent quality and improving the integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

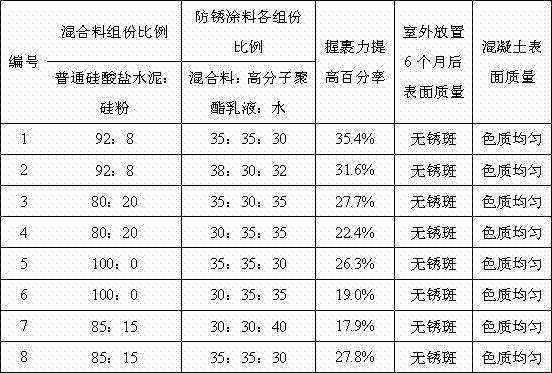

Examples

Embodiment 1

[0034] 1. Weigh a certain amount of ordinary portland cement and silicon powder according to the ratio of mass ratio of 90:10, put them into a dry mixer, and stir for 3 minutes to make a mixture;

[0035] 2. Weigh the mixture, polymer polyester emulsion and water according to a certain mass ratio, wherein the mixture accounts for 30 parts of the total mass, the polymer polyester emulsion accounts for 35 parts of the total mass, and water accounts for 35 parts of the total mass .

[0036] 3. Put the weighed materials into the forced mixer and stir continuously for 4 minutes.

[0037] 4. Put the stirred modified polyester anti-rust coating slurry into a container (such as a soft leather bucket), use a wire brush to remove rust spots or other impurities on the surface of the steel bar, and then use a brush to remove the modified polyester anti-rust coating slurry Brush evenly on the steel bar, after the surface of the steel bar is covered with modified polyester anti-rust paint ...

Embodiment 2

[0039] 1. Weigh a certain amount of ordinary Portland cement and silica fume according to the mass ratio of 92:8, put them into a dry mixer, and stir for 3 minutes to make a mixture;

[0040] 2. Weigh the mixture, polymer polyester emulsion and water according to a certain mass ratio, wherein the mixture accounts for 40 parts of the total mass, the polymer polyester emulsion accounts for 25 parts of the total mass, and water accounts for 35 parts of the total mass .

[0041] 3. Put the weighed material into the forced mixer and stir continuously for 3 minutes.

[0042] 4. Put the stirred modified polyester anti-rust coating slurry into a container (such as a soft leather bucket), use a wire brush to remove rust spots or other impurities on the surface of the steel bar, and then use a brush to remove the modified polyester anti-rust coating slurry Brush evenly on the steel bars. After the surface of the steel bars is covered with the modified polyester anti-rust paint slurry, ...

Embodiment 3

[0044] 1. Weigh a certain amount of ordinary portland cement and silica fume according to the mass ratio of 85:15, put them into a dry mixer, and stir for 4 minutes to make a mixture;

[0045] 2. Weigh the mixture, polymer polyester emulsion and water according to a certain mass ratio, wherein the mixture accounts for 35 parts of the total mass, the polymer polyester emulsion accounts for 25 parts of the total mass, and water accounts for 40 parts of the total mass .

[0046] 3. Put the weighed material into the forced mixer and stir continuously for 3 minutes.

[0047] 4. Put the stirred modified polyester anti-rust coating slurry into a container (such as a soft leather bucket), use a wire brush to remove rust spots or other impurities on the surface of the steel bar, and then use a brush to remove the modified polyester anti-rust coating slurry Brush evenly on the steel bar, after the surface of the steel bar is covered with modified polyester anti-rust paint slurry, put it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com