Heteropolyacid-containing aromatics hydrogenation catalyst and preparation method thereof

A technology of aromatic hydrocarbon hydrogenation and heteropoly acid, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogenation to hydrocarbons, etc. The effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Select the carrier: the carrier is 40-60 mesh and the specific surface is 380m 2 / g SiO 2 particles.

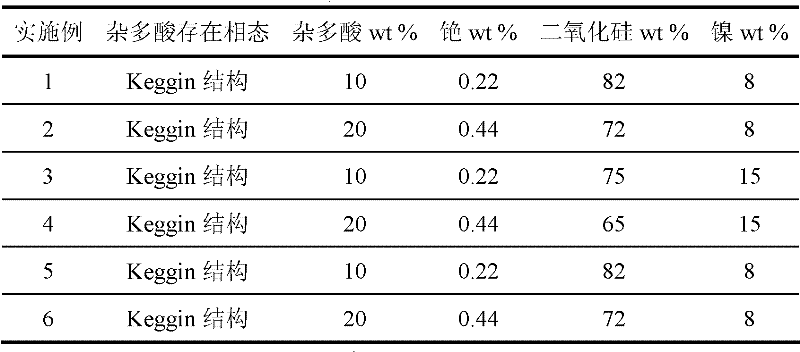

[0020] 2) Catalyst preparation: 106 mL of nickel nitrate solution with a concentration of 1 mol / L and 5.6 mL with a concentration of 3.0×10 -4 The cesium carbonate solution of mol / L was added to 82g of the above-mentioned carrier SiO 2 , let it stand for 12 hours, and then dry it at 110°C for 6 hours. The dried solid was raised to 400°C at a rate of 10°C / min in a muffle furnace, and kept at a constant temperature for 4 hours. Immerse the calcined solid in an aqueous solution containing 10g of phosphotungstic acid, let it stand for 8 hours, then dry it at 120°C for 6 hours, and press the dried material into tablets to obtain the catalyst. The chemical composition and heteropolyacid phase of the prepared catalyst are listed in Table 1.

[0021] 3) Evaluation conditions: the prepared catalyst was reduced in a hydrogen atmosphere at 400° C. for 4 hours. After the ...

Embodiment 2

[0023] 1) Select the carrier: the carrier is 40-60 mesh and the specific surface is 380m 2 / g SiO 2 particles.

[0024] 2) Catalyst preparation: 106 mL of nickel nitrate solution with a concentration of 1 mol / L and 11.4 mL with a concentration of 3.0×10 -4 The cesium carbonate solution of mol / L was added to 72g of the above-mentioned carrier SiO 2 , let it stand for 12 hours, and then dry it at 110°C for 6 hours. The dried solid was raised to 400°C at a rate of 10°C / min in a muffle furnace, and kept at a constant temperature for 4 hours. Immerse the calcined solid in 20g of phosphotungstic acid aqueous solution, let it stand for 8 hours, then dry it at 120°C for 6 hours, and press the dried material into tablets to obtain the catalyst. The chemical composition and heteropolyacid phase of the prepared catalyst are listed in Table 1.

[0025] 3) Evaluation conditions: the prepared catalyst was reduced in a hydrogen atmosphere at 400° C. for 4 hours. After the reduction is ...

Embodiment 3

[0027] 1) Select the carrier: the carrier is 40-60 mesh and the specific surface is 380m 2 / g SiO 2 particles.

[0028] 2) Catalyst preparation: 200mL of nickel nitrate solution with a concentration of 1mol / L and 5.6mL with a concentration of 3.0×10 -4 The cesium carbonate solution of mol / L was added to 75g of the above-mentioned carrier SiO 2 , let it stand for 12 hours, and then dry it at 110°C for 6 hours. The dried solid was raised to 400°C at a rate of 10°C / min in a muffle furnace, and kept at a constant temperature for 4 hours. Immerse the calcined solid in an aqueous solution containing 10g of phosphotungstic acid, let it stand for 8 hours, then dry it at 120°C for 6 hours, and press the dried material into tablets to obtain the catalyst. The chemical composition and heteropolyacid phase of the prepared catalyst are listed in Table 1.

[0029] 3) Evaluation conditions: the prepared catalyst was reduced in a hydrogen atmosphere at 400° C. for 4 hours. After the red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com