System and method for automatically controlling multi-wire cutting machine

An automatic control system, multi-wire cutting machine technology, applied in the direction of digital control, electrical program control, etc., to achieve the effect of good consistency, high degree of automation, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

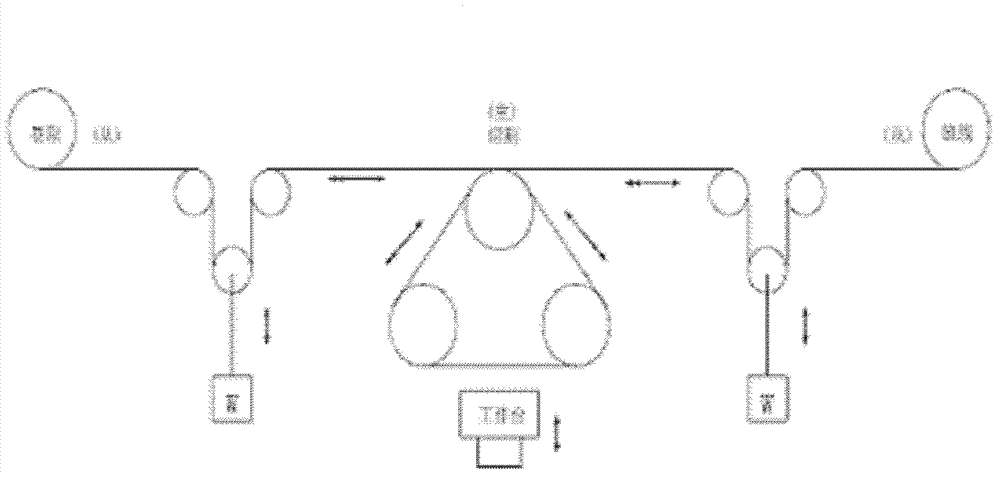

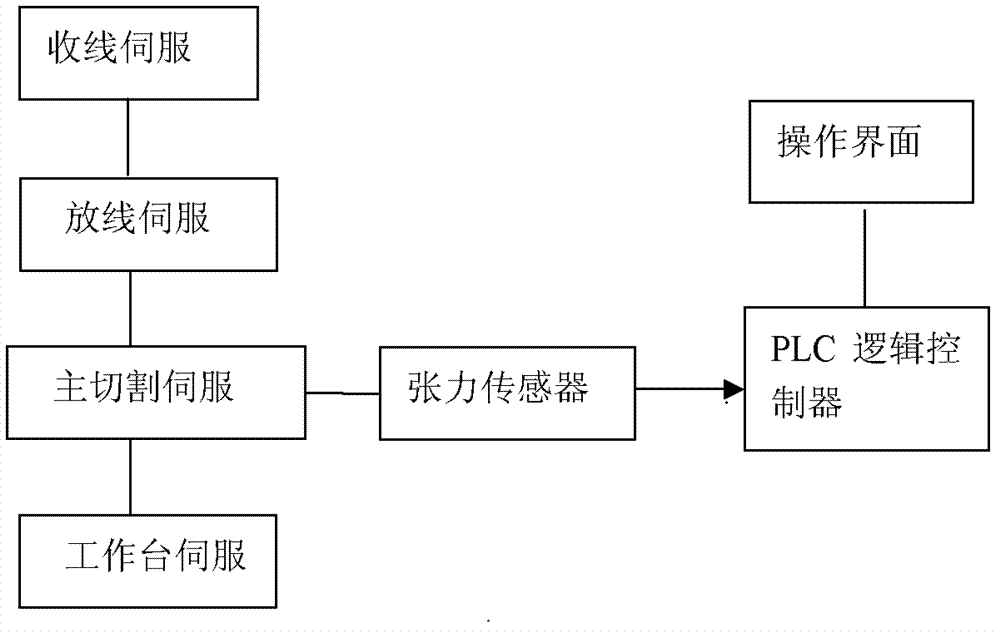

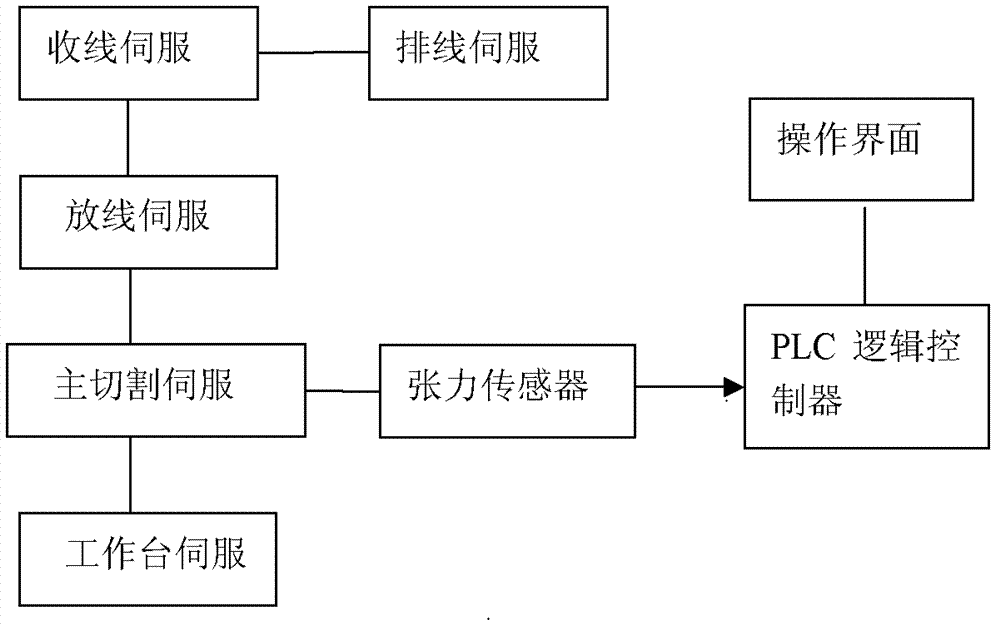

[0029] Such as figure 1 with 2 As shown, it is an automatic control system of a multi-wire cutting machine according to Embodiment 1 of the present invention, and the system includes:

[0030] The workbench servo is used to drive the cutting material to perform positioning movement according to the preset process parameters;

[0031] The main cutting servo, pay-off servo and take-up servo are used to control the movement of cutting, pay-off and take-up respectively;

[0032] Tension sensor, used to collect the tension of pay-off and take-up;

[0033] A PLC logic controller is used to perform PID calculations according to the tension of the pay-off and take-up, and adjust the speed ratio of the pay-off servo to the main cutting servo and the speed ratio of the take-up servo to the main cutting servo to realize The main cutting servo, the linkage of the pay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com