Composite structural target for arc ion plating deposition magnetic material coating and application of composite structural target

An arc ion plating and magnetic material technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of reducing the service life of the target material, complicated equipment operation, increasing cost, etc., and achieve stable and uniform engraving. corrosion, low cost, and simple device fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Such as Figure 5 As shown, the composite target material composed of the metal titanium target shell 7 and the cobalt alloy target material 8 (Si: 3-5wt.%, Fe: 8-10wt.%, Co: balance) inside the metal titanium target shell 7 is used. , the metal titanium target shell 7 and the cobalt alloy target 8 are fixed by threads, which is compared with the use of the common cobalt alloy target with the same composition.

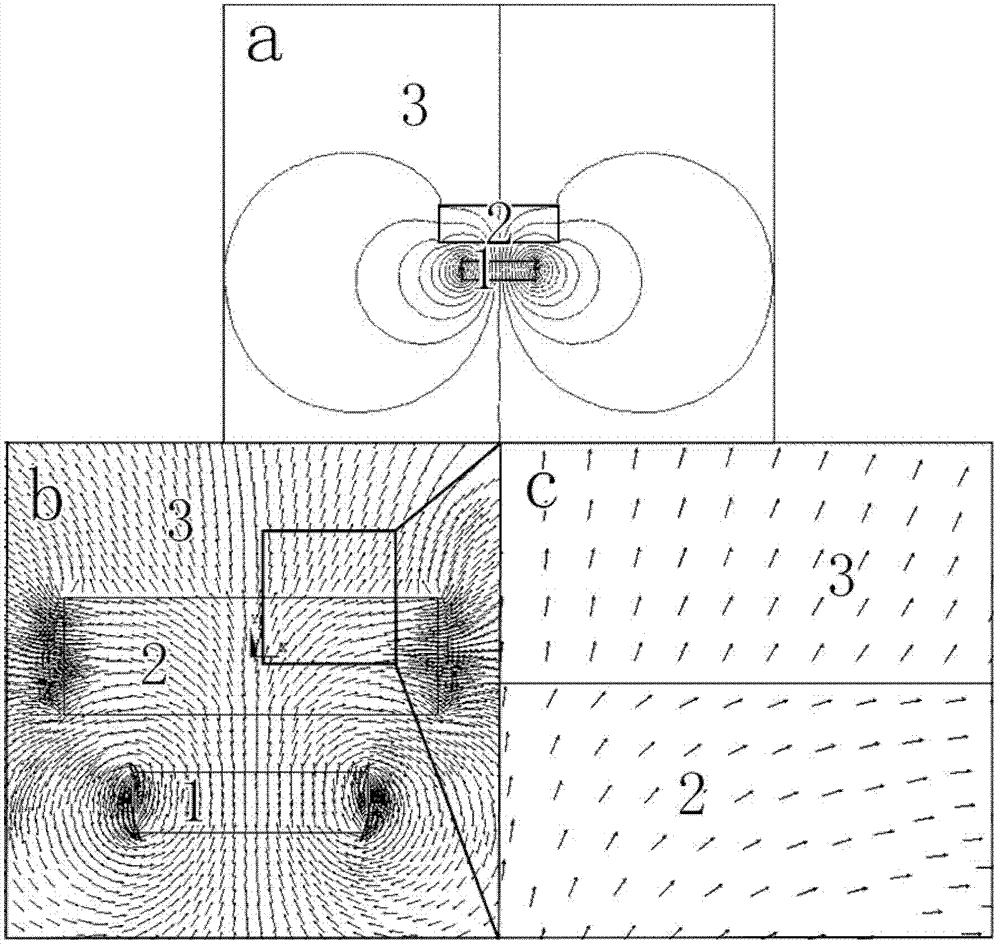

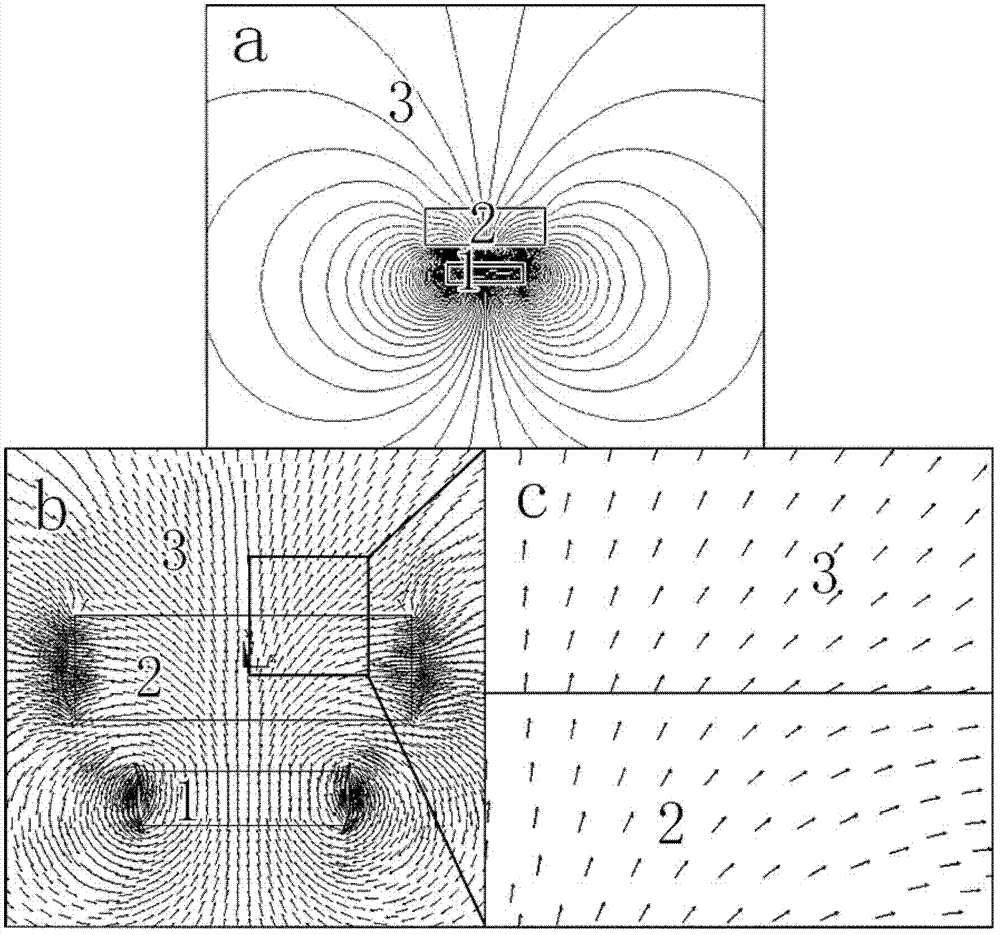

[0045] Figure 7 a-h are video screenshots of the process of using a common cobalt alloy target. It can be seen from the figure that the arc spot moves quickly to the target edge for etching after arc ignition. The reason is that at lower temperatures (lower than the Curie temperature), the transverse magnetic field at the edge of the target is dense (see figure 1 a-c), and the metal or ceramic target shell with no low saturation vapor pressure and low secondary electron emission yield at the edge is etched in the center of the magnetic target, resulting in th...

Embodiment 2

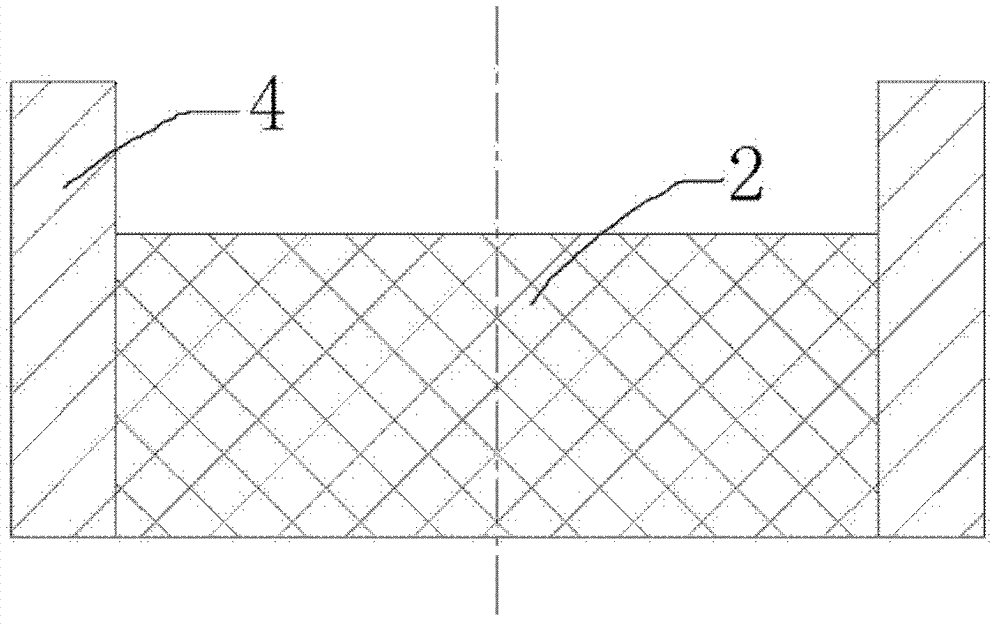

[0050] Such as Figure 6 As shown, the zirconia ceramic target shell 9 plasma-sprayed on the stainless steel ring and the cobalt alloy target 8 (Si: 3-5wt.%, Fe: 8 ~10wt.%, Co: the balance) composed of a composite target, the zirconia ceramic target shell 9 and the cobalt alloy target 8 that are plasma sprayed on the stainless steel ring are fixed by bolts, and the two parts of the composite target are fixed with the same composition of cobalt The use of alloy common targets is compared.

[0051] Figure 9 a-h are video screenshots of the use process of zirconia-cobalt alloy composite targets. At working temperature, zirconia ceramics are insulators with extremely low secondary electron emission, and their saturated vapor pressure is much lower than that of cobalt alloys. Therefore, the arc spot is more likely to be stably etched on the cobalt alloy target, so that the arc spot is forcibly confined to the center of the magnetic target. Until the self-heating effect of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com