Flame-retardant PC (polycarboante)/PET (polyethylene terephthalate) composite material and preparation method thereof

A composite material and flame retardant technology, applied in the field of flame retardant PC/PET composite material and its preparation, can solve the problems of easy embrittlement and poor effect, and achieve the effect of excellent low temperature impact performance and good filling fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

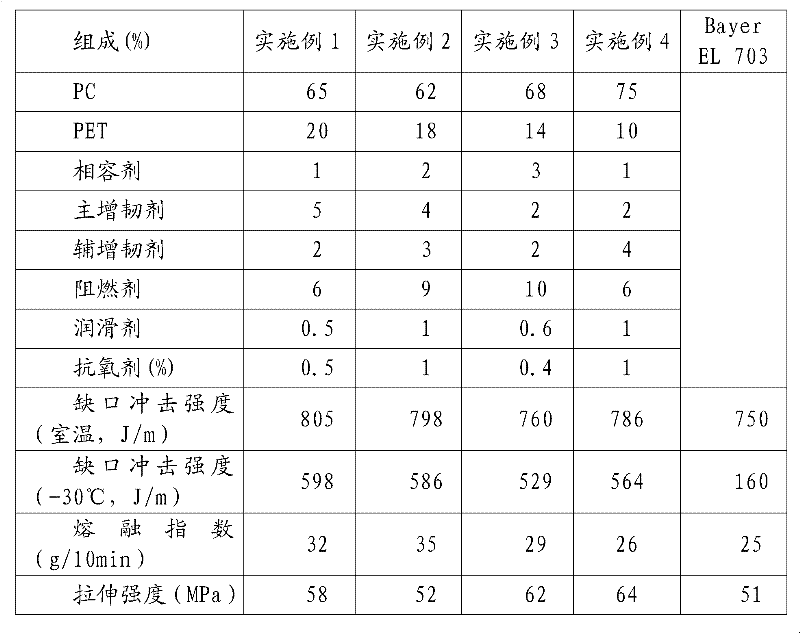

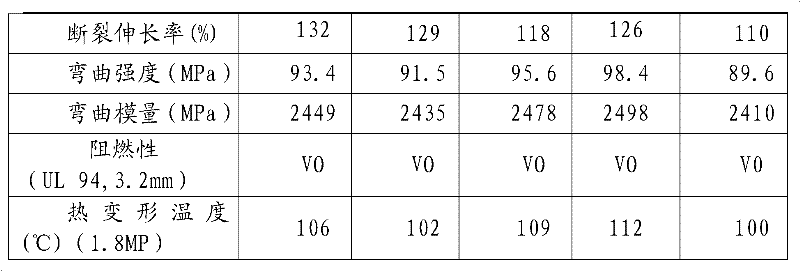

Embodiment 1

[0037] Prepare the premix according to the following weight percentage: polycarbonate (GE EXL1414) 65%, PET (FC-01-68) 20%, compatibilizer (PETG AN0004) 1%, main toughening agent 5% (S2001), Auxiliary toughener (1125AC) 2%, lubricant (EBS 120) 0.5%, antioxidant (1010) 0.5%, flame retardant (BC-58) 6%. Add the dry PC and PET into the high-speed batch mixer together, add antioxidant, toughener, flame retardant, compatibilizer and main and auxiliary lubricants and mix for 5-10 minutes, and put the mixed premix in Granulated by melt extrusion in a twin-screw machine. The process is: twin-screw first stage temperature 220-230°C, second stage temperature 230-240°C, third stage temperature 240-250°C, mold temperature 60-100°C, residence time 1-2 minutes, pressure 10-15MPa.

Embodiment 2

[0039] Prepare the premix according to the following weight percentage: polycarbonate (GE EXL1414) 62%, PET (CZ5011) 18%, compatibilizer (PETG AN0004) 2%, primary toughening agent (S2001) 4%, auxiliary toughening agent (1125AC) 3%, lubricant (EBS 120) 0.6%, antioxidant (1010) 0.4%, flame retardant (BC-58) 9%. Add the dry PC and PET into the high-speed batch mixer together, add antioxidant, toughener, flame retardant, compatibilizer and main and auxiliary lubricants and mix for 5-10 minutes, and put the mixed premix in Granulated by melt extrusion in a twin-screw machine. The process is: twin-screw first stage temperature 220-230°C, second stage temperature 230-240°C, third stage temperature 240-250°C, mold temperature 60-100°C, residence time 1-2 minutes, pressure 10-15MPa.

Embodiment 3

[0041] Prepare the premix according to the following weight percentage: polycarbonate (GE EXL1414) 68%, PET (CZ5011) 14%, compatibilizer (PETG AN0004) 3%, primary toughening agent (S2001) 2%, auxiliary toughening agent (1125AC) 2%, lubricant (EBS 120) 1%, antioxidant (1010) 1%, flame retardant (BC-58) 10%. Add the dry PC and PET into the high-speed batch mixer together, add antioxidant, toughener, flame retardant, compatibilizer and main and auxiliary lubricants and mix for 5-10 minutes, and put the mixed premix in Granulated by melt extrusion in a twin-screw machine. The process is: twin-screw first stage temperature 220-230°C, second stage temperature 230-240°C, third stage temperature 240-250°C, mold temperature 60-100°C, residence time 1-2 minutes, pressure 10-15MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com