A low-cost and high-fluidity halogen-free flame-retardant PC material and preparation method thereof

A high-fluidity, low-cost technology, applied in the field of polycarbonate modification, can solve the problems of damage to mechanical properties, low decomposition temperature, and low addition amount, achieving small loss of mechanical properties, high flame retardant efficiency, and easy injection molding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

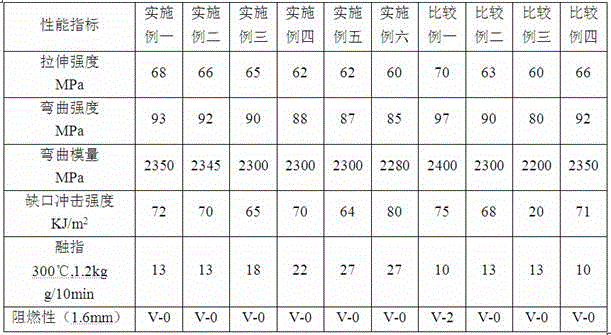

Examples

Embodiment 1

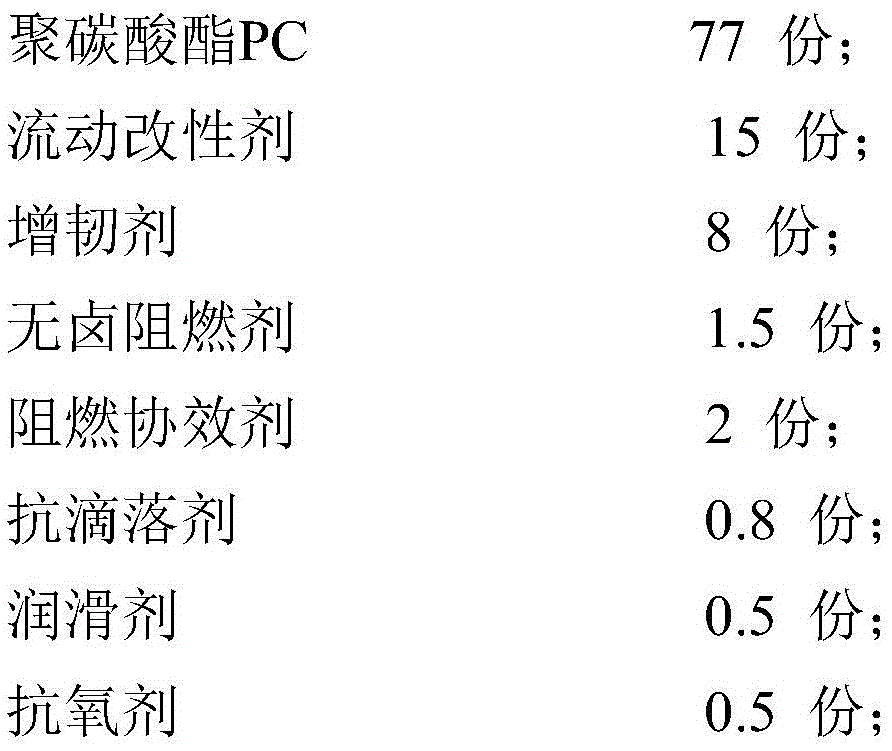

[0038] Example 1: Prepare the premix according to the following formula: 100 parts of polycarbonate, 0.5 part of sulfonate halogen-free flame retardant, 0.4 part of special modified anti-dripping agent, 0.5 part of lubricant, and 0.5 part of antioxidant . Put the mixed premixed material in a twin-screw extruder for melt extrusion and granulation, and dry the obtained granules at 100°C for 2 hours to obtain the finished product. The process is as follows: the screw temperature of each section of the twin-screw extruder is controlled between 250-275°C, and the screw speed is 300 rpm.

Embodiment 2

[0039] Example 2: Prepare the premix according to the following formula: 100 parts of polycarbonate, 0.2 part of sulfonate halogen-free flame retardant, 0.5 part of organosilicon synergistic flame retardant, 0.4 part of special modified anti-dripping agent, 0.5 parts of lubricant, 0.5 parts of antioxidant. Put the mixed premixed material in a twin-screw extruder for melt extrusion and granulation, and dry the obtained granules at 100°C for 2 hours to obtain the finished product. The process is as follows: the screw temperature of each section of the twin-screw extruder is controlled between 250-275°C, and the screw speed is 300 rpm.

Embodiment 3

[0040] Example 3: Prepare the premix according to the following formula: 92 parts of polycarbonate, 5 parts of flow modifier, 3 parts of toughening agent, 0.6 part of sulfonate halogen-free flame retardant, silicone synergistic flame retardant 0.5 parts, 0.5 parts of special modified anti-dripping agent, 0.5 parts of lubricant, 0.5 parts of antioxidant. Put the mixed premixed material in a twin-screw extruder for melt extrusion and granulation, and dry the obtained granules at 100°C for 2 hours to obtain the finished product. The process is as follows: the screw temperature of each section of the twin-screw extruder is controlled between 250-275°C, and the screw speed is 300 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com