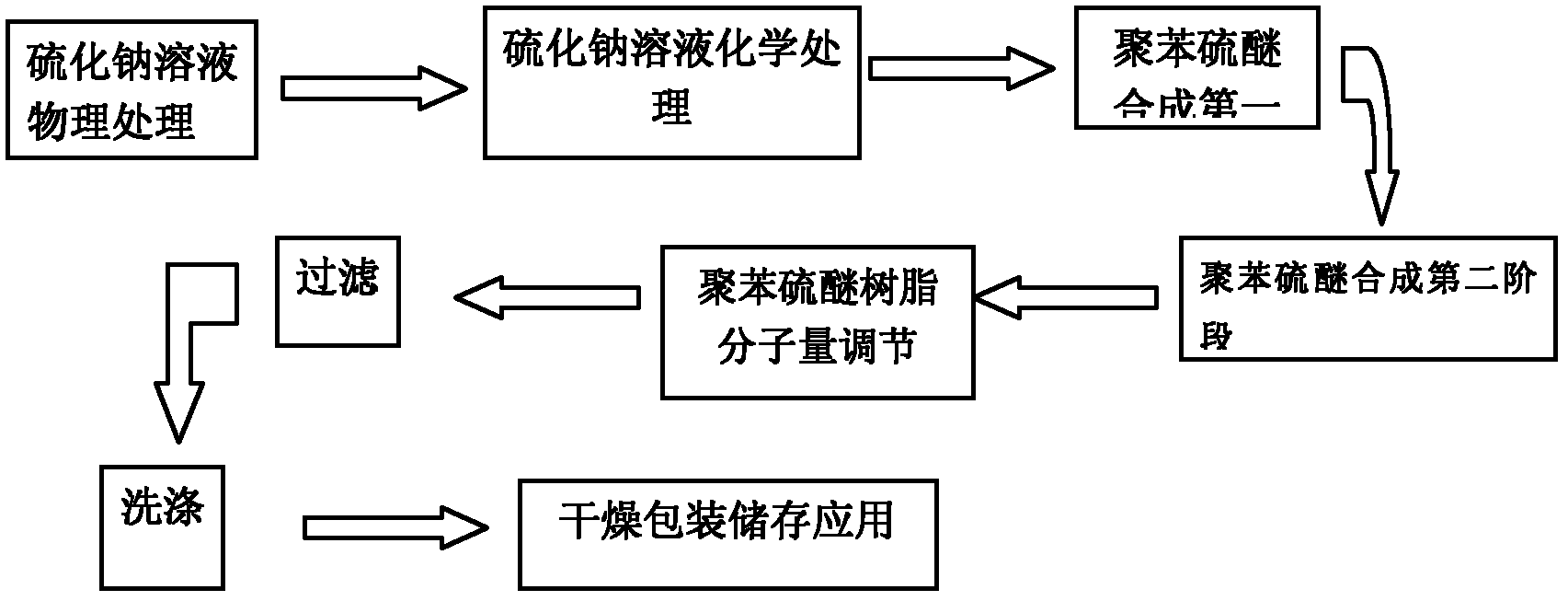

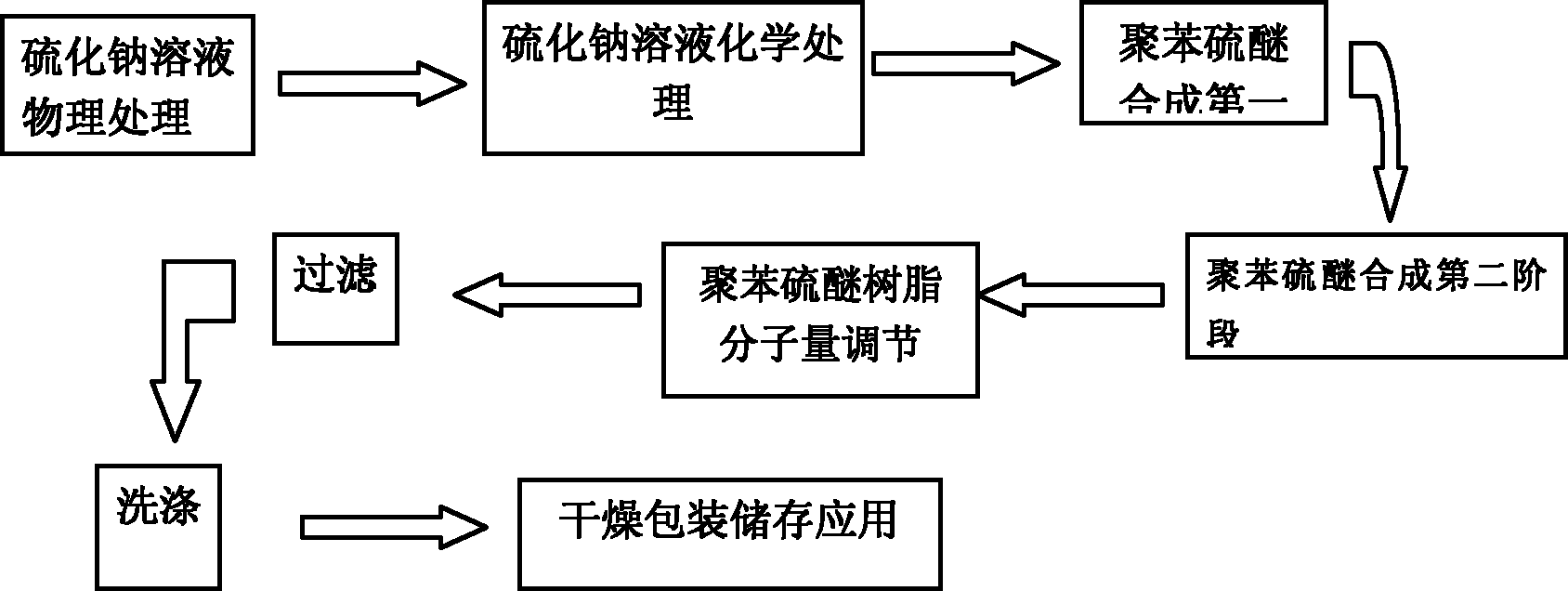

Synthesis process for polyphenylene sulfide resin

A polyphenylene sulfide resin and a synthesis process technology are applied in the field of polymer material resin synthesis to achieve the effects of shortening synthesis time, improving production efficiency and increasing reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Under the condition of online infrared monitoring system control and nitrogen protection, in the sodium sulfide dehydration treatment stage, 100mol sodium sulfide pentahydrate crystals were added to a 316L stainless steel reactor, under the condition of nitrogen protection with a purity of 99.995% v / v, and Heating to 120°C to fully dissolve the sodium sulfide, and then input the sodium sulfide solution into the pipeline filter with a heat preservation temperature of 120°C for the treatment of mechanical impurities. The filter element of the filter element is a pure titanium metal filter with a pore size of 0.01 um, the flow rate is 60m 3 / h, and then the sodium sulfide solution treated by the pipeline filter is input into the next stage 316L stainless steel reactor for use.

[0028] 2) Under the condition of online infrared monitoring system control and nitrogen protection, add the sodium sulfide aqueous solution obtained in 1) under the condition of nitrogen protecti...

Embodiment 2

[0036] 1) Under the condition of online infrared monitoring system control and nitrogen protection, in the sodium sulfide dehydration treatment stage, 100mol sodium sulfide pentahydrate crystals were added to a 316L stainless steel reactor, under the condition of nitrogen protection with a purity of 99.995% v / v, and Heating to 130°C to fully dissolve the sodium sulfide, and then input the solution into a pipeline filter with a heat preservation temperature of 130°C for processing of mechanical impurities. The filter element of the filter is a pure titanium metal filter with a pore size of 0.01um. The flow rate is 40m 3 / h, and then the sodium sulfide treated by the pipeline filter is the solution input to the next stage 316L stainless steel reactor.

[0037] 2) Under the condition of online infrared monitoring system control and nitrogen protection, add the sodium sulfide aqueous solution obtained in 1) under the condition of nitrogen protection, add 10% mol of 13mol NaOH in t...

Embodiment 3

[0045] 1) Under the condition of online infrared monitoring system control and nitrogen protection, in the sodium sulfide dehydration treatment stage, 100mol sodium sulfide pentahydrate crystals were added to a 316L stainless steel reactor, under the condition of nitrogen protection with a purity of 99.995% v / v, and Heating to 125°C to fully dissolve the sodium sulfide, and then input the solution into a pipeline filter with a heat preservation temperature of 125°C for processing of mechanical impurities. The filter element of the filter is a pure titanium metal filter with a pore size of 0.01um. The flow rate is 50m 3 / h, and then the sodium sulfide treated by the pipeline filter is the solution input to the next stage 316L stainless steel reactor.

[0046] 2) Under the condition of online infrared monitoring system control and nitrogen protection, add the sodium sulfide aqueous solution obtained in 1) under the condition of nitrogen protection, add 10% mol of 12mol NaOH in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com