Diameter reducing machine for small-sized pipe

A technology of reducing machine and pipe body, applied in the direction of the mandrel, etc., can solve the problems of inconsistent wall thickness, increased density, thickened pipe wall, etc., and achieve the effects of reducing production costs, good appearance quality, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

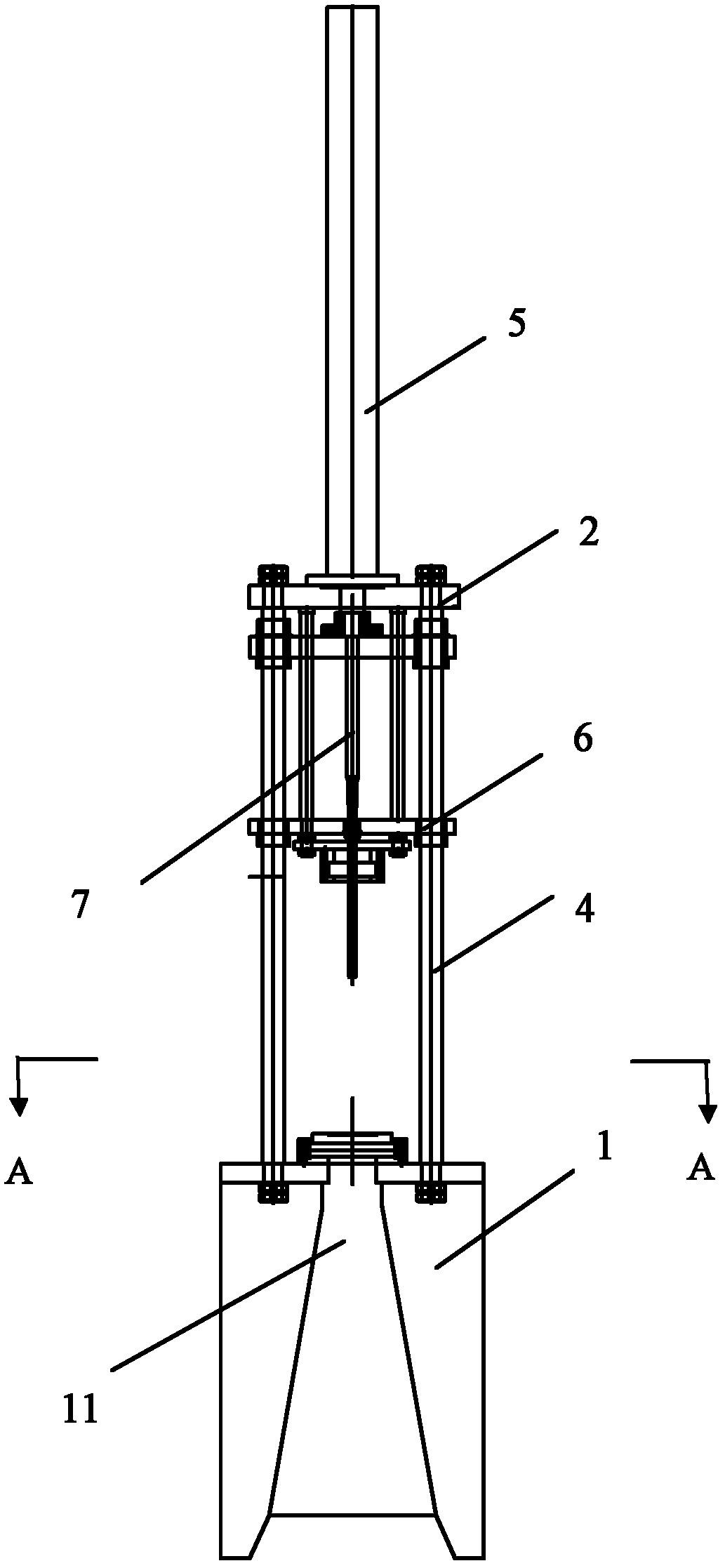

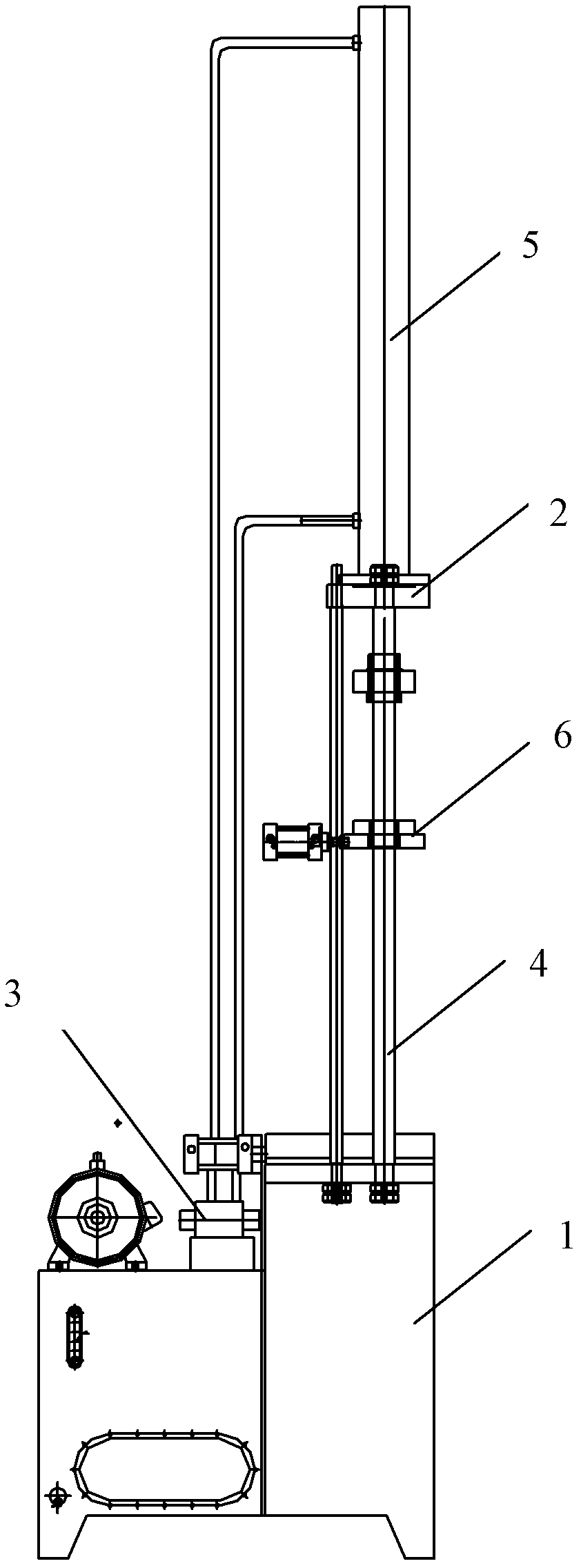

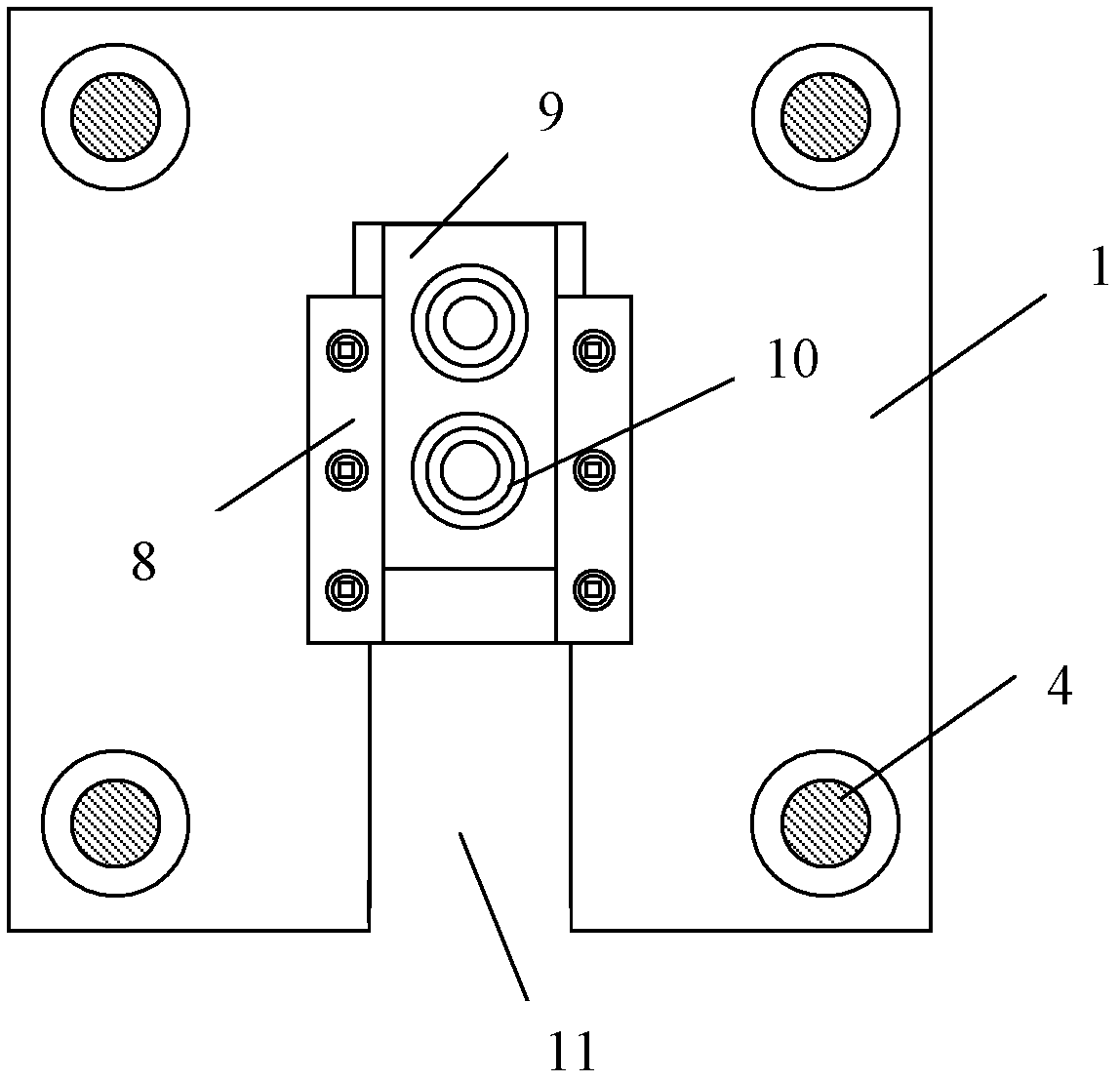

[0011] The small pipe body reducing machine provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0012] Such as Figure 1-Figure 3 As shown, the small pipe body reducing machine provided by the present invention includes a bracket 1, an oil cylinder support frame 2, an oil pump 3, a plurality of guide rails 4, an oil cylinder 5, a stripper plate 6, a mandrel 7, two bases 8, and a slide plate 9 and a reducing sleeve 10; wherein the support 1 is arranged on the ground, and an opening 11 is formed from the center part to the front; the oil pump 3 is installed on the rear surface of the support 1, and its inlet end is connected with the hydraulic system through an oil pipe; The root guide rails 4 are vertically installed on the surface of the support 1 outside the opening 11, and the top surface is provided with an oil cylinder support frame 2; the oil cylinder 5 is vertically installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com