Method for simultaneously determining contents of various preservatives in soy by capillary gas chromatography internal standard method

A technology of gas chromatography and internal standard method, which is applied in the field of detection of various preservatives in soy sauce, can solve the problems of unsatisfactory precision and accuracy, increased operational errors in the measurement steps, difficult stratification, etc., and achieves sample pretreatment time The effect of shortening, improving utilization rate, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

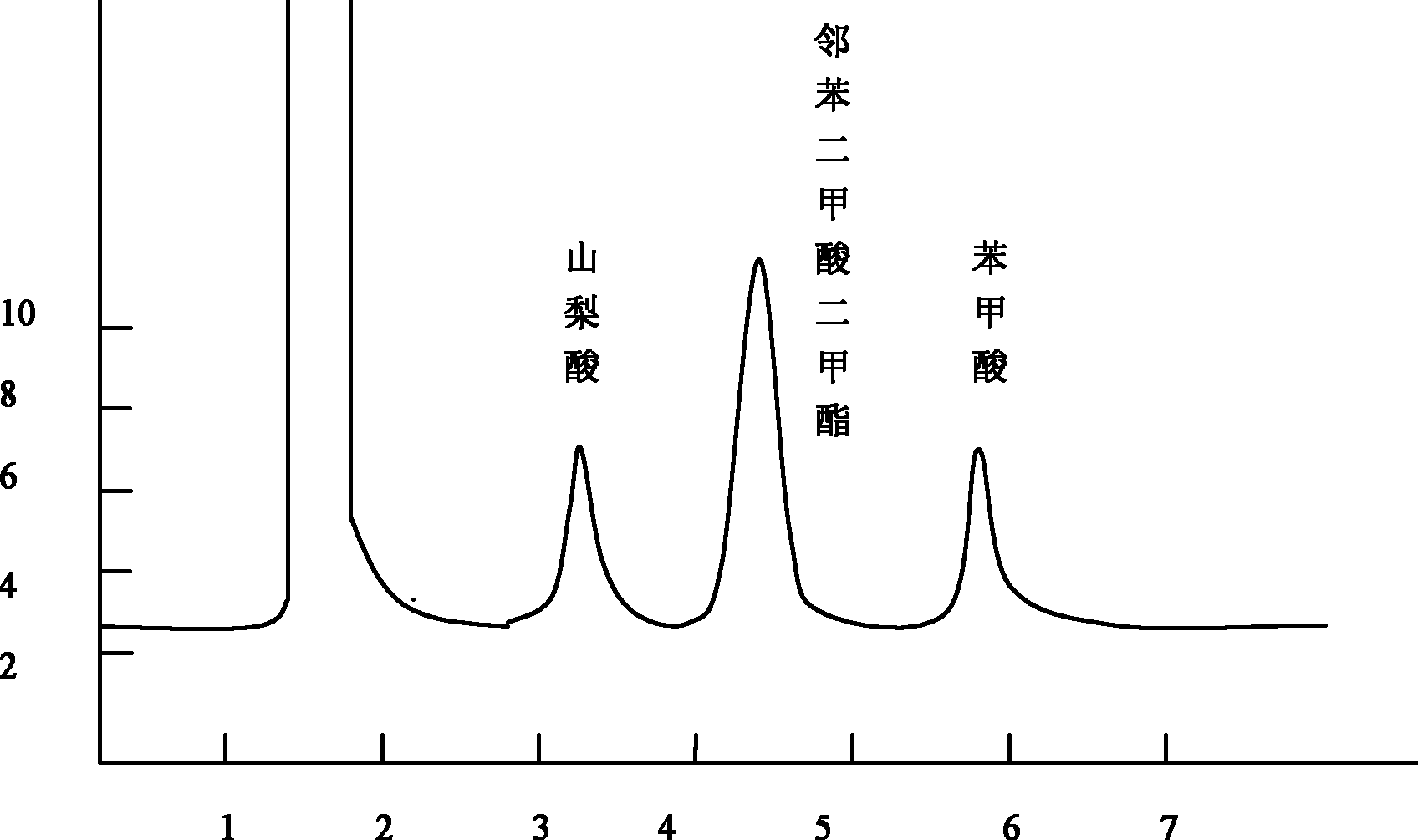

[0023] 1. Chromatographic conditions:

[0024] Gas chromatograph equipped with FID detector;

[0025] The capillary column is DB-WAX (30m×0.32mm×0.25μm)

[0026] The column temperature is 210°C, the vaporization chamber and the detection chamber are both 230°C

[0027] Manual injection 1.0μl

[0028] The carrier gas is high-purity nitrogen, the column head pressure is 0.07Mpa, and the split ratio is 100:1

[0029] 2. Correction Factor Determination

[0030] Preparation of standard solution: Accurately weigh 0.2g each of benzoic acid and sorbic acid, dissolve in acetone and dilute to 100ml;

[0031] Prepare internal standard solution: Accurately weigh 0.2 g of methyl heptadecanoate, dissolve it in acetone and set the volume to 100 ml;

[0032] Preparation of standard solution: Take an appropriate amount of standard solution and mix with internal standard solution, the concentration of internal standard is 0.4g / L, and the concentration of standard substance is 0.2, 0.4, 0.6...

Embodiment 2

[0039] 1. Chromatographic conditions:

[0040] Gas chromatograph equipped with FID detector;

[0041] The capillary column is DB-WAX (30m×0.32mm×0.25μm)

[0042] The column temperature is 210°C, the vaporization chamber and detection room temperature are 230°C

[0043] Manual injection 0.5μl

[0044] The carrier gas is high-purity nitrogen, the column head pressure is 0.07Mpa, and the split ratio is 100:1

[0045] 2. Correction Factor Determination

[0046] Preparation of standard solution: Accurately weigh 0.2g each of benzoic acid, sorbic acid, dehydroacetic acid, methyl p-hydroxybenzoate, ethyl p-hydroxybenzoate, and propyl p-hydroxybenzoate, dissolve in acetone and dilute to 100ml;

[0047] Prepare internal standard solution: Accurately weigh 0.2 g of methyl heptadecanoate, dissolve it in acetone and set the volume to 100 ml;

[0048] Preparation of standard solution: Take an appropriate amount of standard solution and mix it with internal standard solution. The conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| carbon number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com