Rolled self-fastening type cable bridge

A cable tray, self-buckling technology, applied in the direction of pipe supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of large cable line loss, use of material resources, poor heat dissipation performance, etc., to achieve material saving , light weight, beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

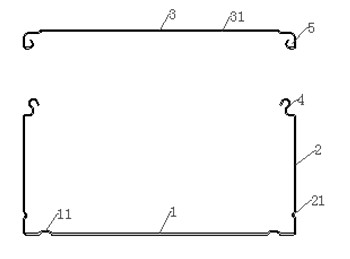

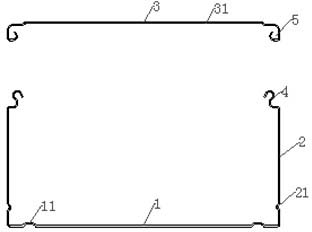

[0015] The main body and cover plate of the self-fastening cable tray involved in the present invention are formed by pultrusion and rolling by cold-rolled steel coils. It is pultruded into an "S" shape and bent; the middle part of the cover plate protrudes into two reinforcing ribs, and the two sides are pultruded inward and bent into a "G" shape. The "G" shaped edge of the cover plate fits closely with the "S" shaped edge of the tank body, and there is no need to use a snap lock device when installing the bridge, which is convenient for installation and disassembly.

[0016] According to different requirements, the bridge frame can be rolled and drawn by stainless steel, aluminum alloy and carbon steel coils and sheets. After forming, it can be painted, sprayed, electro-galvanized, hot-dip galvanized or surface oxidation treatment and other anti-corrosion treatments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com