Novel vortex-preventing cone for water feeding of water pump

A technology for anti-vortex cones and water pumps, which is applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problems of ineffective prevention of bottom vortex, improve inlet water flow conditions, reduce pressure fluctuations, and design reasonably Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

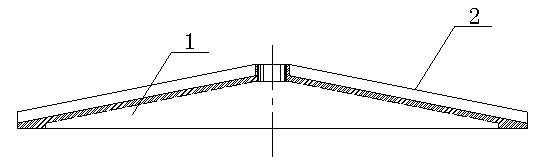

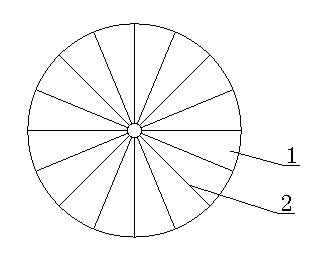

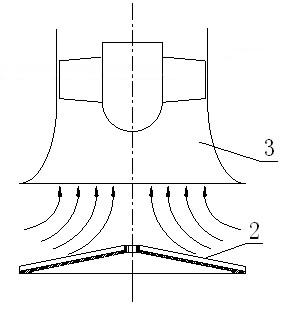

[0026] A new type of water pump inlet anti-vortex cone. A flat conical anti-vortex cone (or a cone with a regular polygonal bottom surface such as a regular triangle or square) is set directly below the 3 port of the water pump suction horn pipe. The distance between the anti-vortex cone and the suction horn pipe mouth Less than the suspended height. The tip of the anti-vortex cone is facing the center of the nozzle of the suction horn of the pump. The conical surface 1 of the anti-vortex cone is provided with uneven anti-vortex teeth 2. The cross-sectional shape of the rack of the anti-vortex cone is rectangular or triangular or trapezoidal. . The plane area of the anti-vortex cone is larger than the area of the nozzle of the suction horn. The cone axis of the flat cone is on the same straight line with the tube center line of the suction horn of the water pump.

[0027] The invention is suitable for various water pump devices. The anti-vortex cone is made of metal or non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com