Composite antibacterial peptide produced by bacillus natto NT-6 and production method thereof

A technology of Bacillus natto and NT-6, which is applied in the biological field, can solve the problems of no identification and no literature on the identification of antibacterial substances of Bacillus natto, and achieve high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

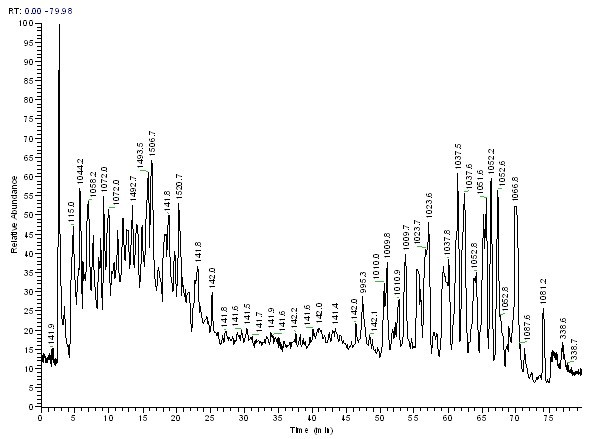

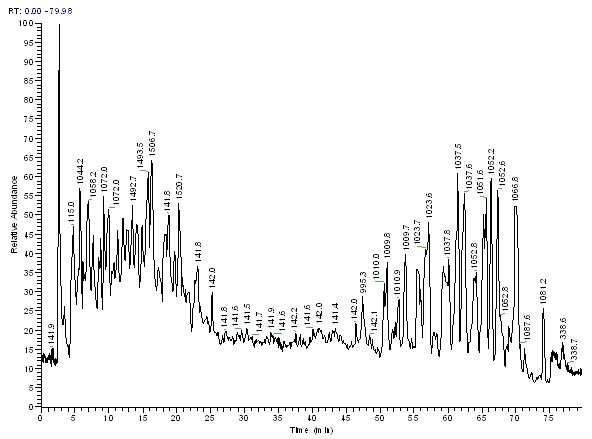

Image

Examples

Embodiment 1

[0027] After expanded cultivation of seeds, submerged fermentation was carried out in a fermenter at 28-35°C for 30-48 hours to accumulate antibacterial metabolites. The fermentation liquid was centrifuged to remove bacteria, and then HCl was added to the supernatant to adjust the pH to 2. Centrifuge after placing, the precipitate is further extracted with 3-5 times of methanol or ethanol, the extract is adsorbed by excipients and dried to obtain the finished product of antibacterial peptide, which is determined by high performance liquid chromatography, and the content of antibacterial peptide is not less than 100g / kg.

Embodiment 2

[0029] Bacillus natto ( Bacillus natto ) After the NT-6 bacterial strain is expanded through the above-mentioned seed medium, carry out liquid submerged fermentation in the above-mentioned liquid fermentation medium in a fermenter at 28-35° C., accumulate antibacterial metabolites for 30-48 hours, and remove the bacteria through centrifugation of the fermentation liquid. Then the supernatant is concentrated and dried to obtain the finished product of the antimicrobial peptide, and the content of the antimicrobial peptide is not less than 100 g / kg as determined by high performance liquid chromatography.

Embodiment 3

[0031] Bacillus natto ( Bacillus natto ) After the NT-6 bacterial strain is expanded through the above-mentioned seed medium, carry out liquid submerged fermentation in the above-mentioned liquid fermentation medium in a fermenter at 28-35° C., accumulate antibacterial metabolites for 30-48 hours, and remove the bacteria through centrifugation of the fermentation liquid. Then the supernatant is concentrated, extracted with 3-5 times of methanol, and dried to obtain the finished antimicrobial peptide. The content of the antimicrobial peptide is not less than 500g / kg as determined by high performance liquid chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com