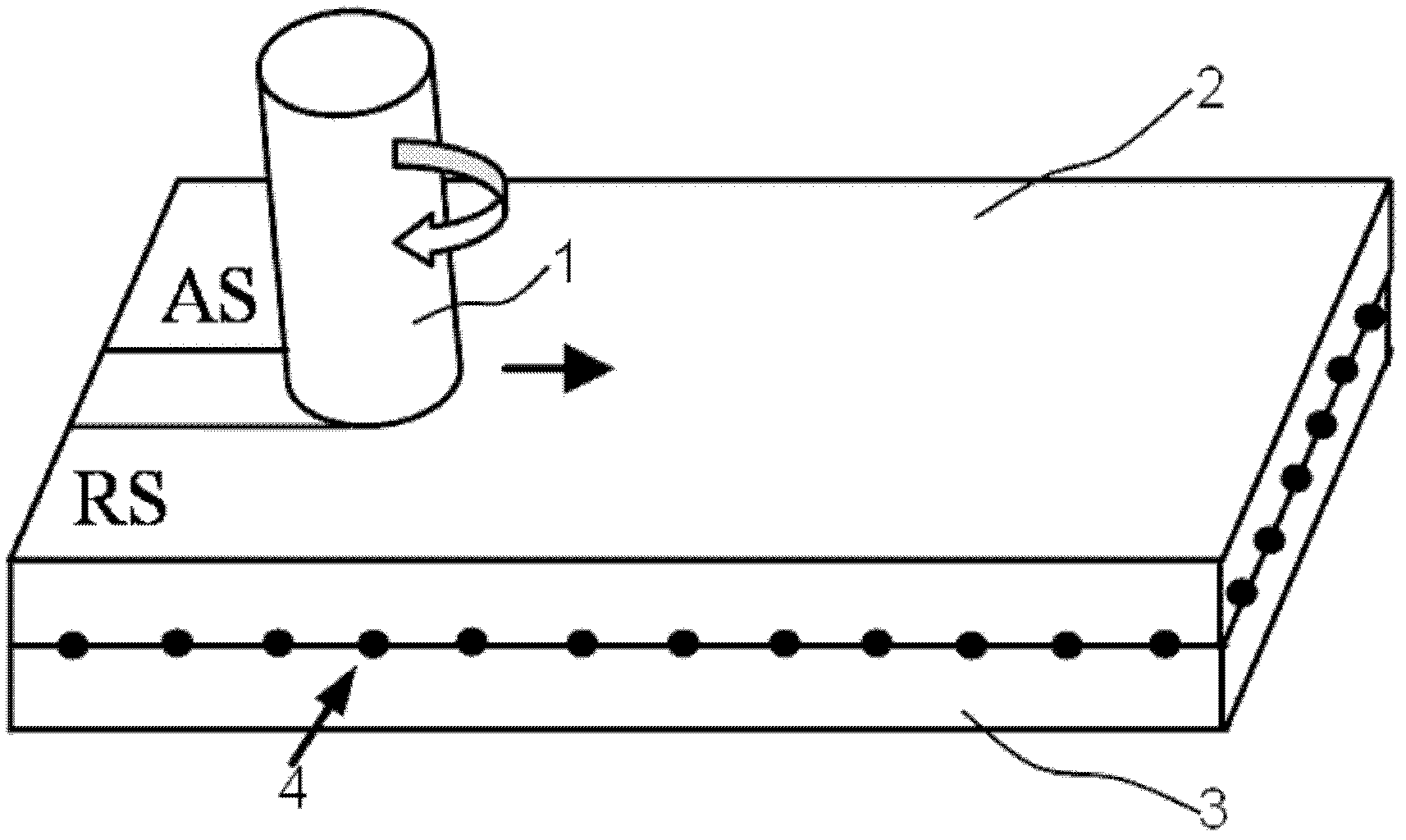

Large-diameter multi-pass pin-less friction stir processing method for fabricating fiber-reinforced metal matrix composites

A friction stir, composite material technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of complicated pressurizing equipment, long construction period, expensive, etc., to improve the appearance flatness, strengthen the forging effect, and avoid waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

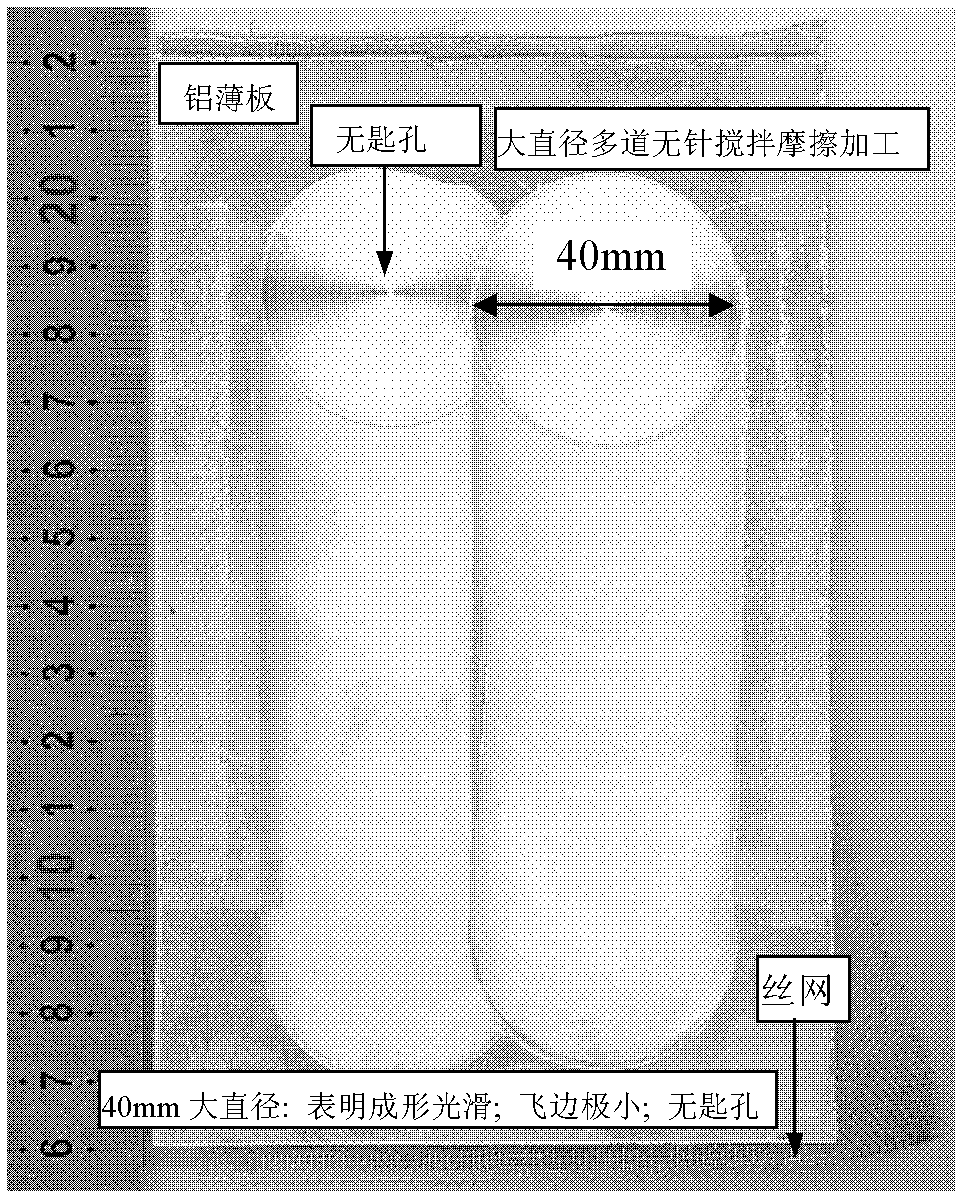

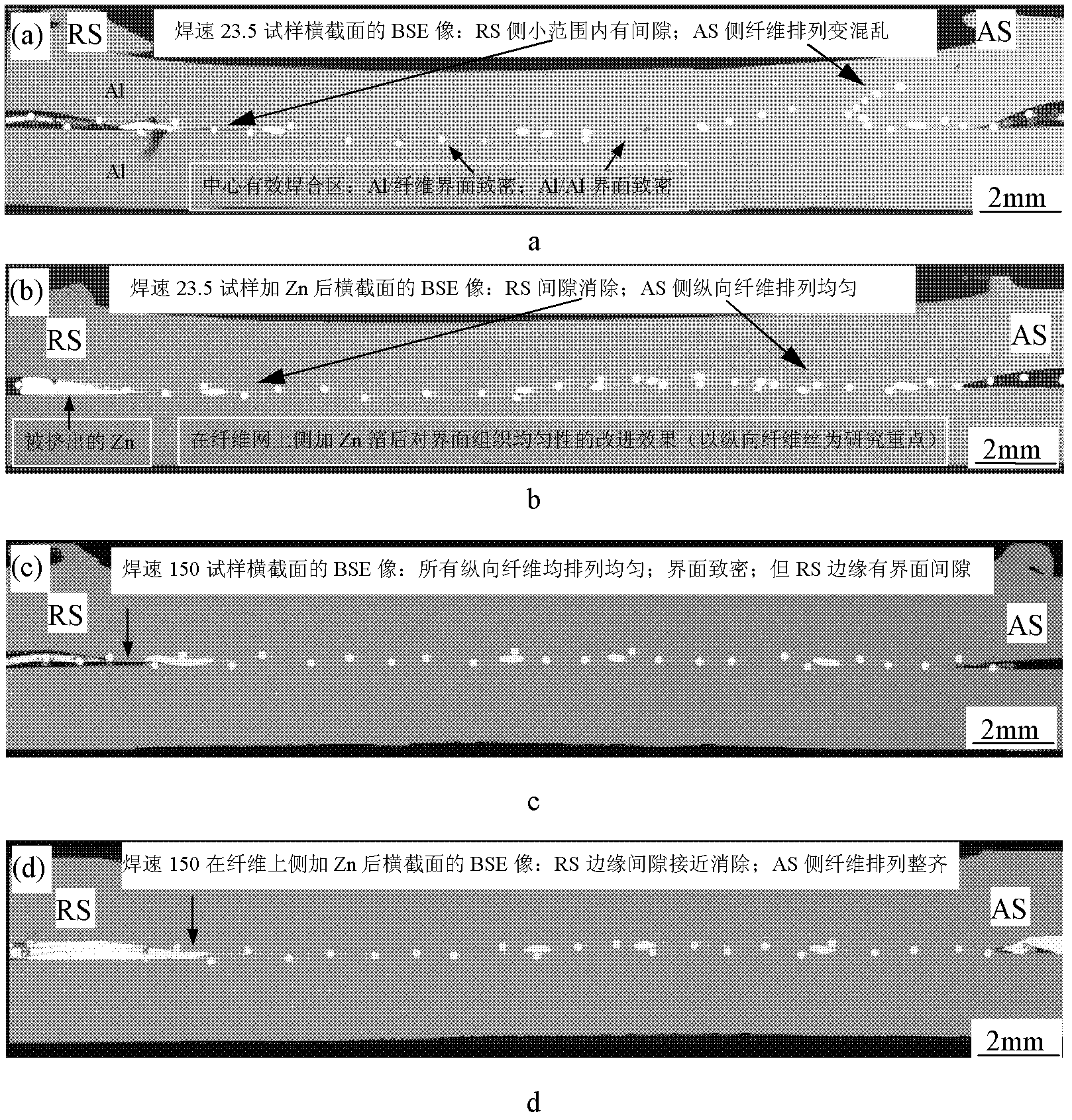

[0030] A specific embodiment is introduced below. In order to save the test cost, the metal substrate used is a commercially available 1.8mm thick pure aluminum plate, and the reinforced body used is a commercially available galvanized steel wire mesh (wire diameter about 150 μm). Cut the aluminum plate into a large sample of 160×100×1.8mm and a small sample of 1000×60×1.8mm. The large sample is welded with a 40-50mm large-diameter multi-channel needle-free cylindrical friction stir tool (limited by the power of the laboratory machine tool - 7.5KW, the large diameters selected in the embodiment are 40 and 50mm; while the usual friction stir welding The diameter of the shoulder is mostly 15-20mm, which is far smaller than the 40-50mm large diameter adopted in the embodiment of the present invention), which is used to study the surface forming influencing factors and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com