Lightweight film solar module and manufacturing method thereof

A technology for solar cells and manufacturing methods, applied to electrical components, circuits, photovoltaic power generation, etc., can solve the problems of high cost, complicated process, and heavy weight of thin-film solar cell components, and achieve weight reduction, simplified production process, and reduced production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

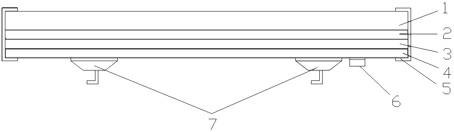

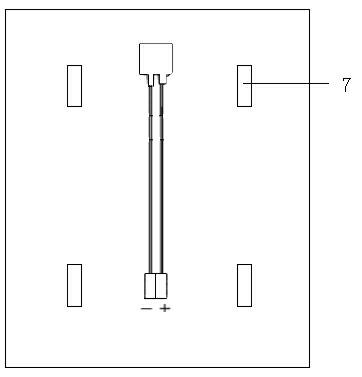

[0017] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0018] A lightweight thin-film solar cell module and a manufacturing method thereof, comprising the following process steps:

[0019] ① Use toughened glass or semi-tempered glass instead of ordinary float glass as the substrate of thin-film solar cells to ensure the mechanical strength of the module and reduce the weight of the module; ② Use reflective packaging materials instead of titanium dioxide back reflection layer or metal back reflection layer and transparent packaging materials to reduce the production cost of components and simplify the production process; ③A polymer composite film containing a metal layer is used as the backsheet of thin-film solar cells to prevent water vapor intrusion and reduce the weight of components; ④The electrodes at the junction box are drawn out The wire is pasted with insulating tape to prevent the electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com