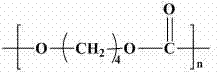

Fully biodegradable aliphatic polycarbonate mulch film and preparation method thereof

A biodegradable, polycarbonate technology, used in plant protection covers and other directions, can solve the problems of limited use range, insufficient weather resistance and water resistance, and achieve improved mechanical properties and water resistance, low decomposition rate, and long residual effect time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh each component according to the following parts by weight: PBC: 50.0, corn starch: 10, PLA: 35, acetochlor (herbicide): 1.5, silicon dioxide (opening agent): 1.0, stearic acid (lubricant) : 1.5, polyethylene glycol (plasticizer): 4.0, dibutyltin maleate (heat-resistant stabilizer): 1.5, ethyl phosphite (antioxidant): 0.1, titanate coupling agent: 0.5, oxalic acid (biodegradation accelerator): 0.15, cerium stearate (photodegradation agent): 0.5.

[0028] Preparation steps and conditions are:

[0029] Put the PBC, starch and PLA weighed in proportion into the high-speed mixer, start stirring at a low speed, and add the weighed herbicide, anti-blocking agent, lubricant, plasticizer, heat-resistant stabilizer, antioxidant Agent, coupling agent, biodegradation accelerator, photodegradation agent, stirring at low speed for 5 minutes, then adding and stirring at high speed for 10 minutes, after stirring evenly, enter the co-rotating twin-screw extruder. Carry out extru...

Embodiment 2

[0033] Weigh each component according to the following parts by weight: PBC: 50.0, starch phosphate: 20, PLA: 20, alachlor: 1.0, superfine calcium carbonate powder: 1.5, zinc stearate: 2.0, polypropylene glycol adipic acid Ester: 6.0, zinc oxide: 2.0, ethyl phosphite: 0.8, titanate coupling agent: 0.8, oxalic acid: 0.8, cerium stearate: 1.0.

[0034] Preparation steps and conditions are:

[0035] Put the PBC, starch and PLA weighed in proportion into the high-speed mixer, start stirring at a low speed, and add the weighed herbicide, anti-blocking agent, lubricant, plasticizer, heat-resistant stabilizer, antioxidant Agent, coupling agent, biodegradation accelerator, photodegradation agent, stirred at low speed for 10 minutes, then added and stirred at high speed for 15 minutes, stirred evenly, and then entered the co-rotating twin-screw extruder. Carry out extrusion granulation at a temperature of 60-180°C, and then use film blowing equipment to blow film to obtain the require...

Embodiment 3

[0039] Weigh each component according to the following parts by weight: PBC: 40.0, acetate starch: 30, PLA: 35, acetochlor: 2.0, silicon dioxide: 2.0, stearic acid: 3.0, epoxy soybean oil: 7.0, hard Calcium fatty acid: 1.5, bisphenol A: 0.15, titanate coupling agent: 1.0, oxalic acid: 0.7, cerium stearate: 2.0.

[0040] Preparation steps and conditions are:

[0041] Put the PBC, starch and PLA weighed in proportion into the high-speed mixer, start stirring at a low speed, and add the weighed herbicide, anti-blocking agent, lubricant, plasticizer, heat-resistant stabilizer, antioxidant Agent, coupling agent, biodegradation accelerator, photodegradation agent, stirring at low speed for 5 minutes, then adding and stirring at high speed for 5 minutes, after stirring evenly, enter the co-rotating twin-screw extruder. Carry out extrusion granulation at a temperature of 60-180°C, and then use film blowing equipment to blow film to obtain the required film. The test results of the per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com