High CTI brominated flame-retardant reinforced PBT material and preparation method thereof

A technology of brominated flame retardants and brominated flame retardants, which is applied in the field of brominated flame retardant reinforced PBT materials and its preparation, can solve the problems of limited application of materials, limited space for improving CTI value, and poor mechanical properties, so as to achieve no precipitation Effect of GWIT value, excellent mechanical properties, and high CTI value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

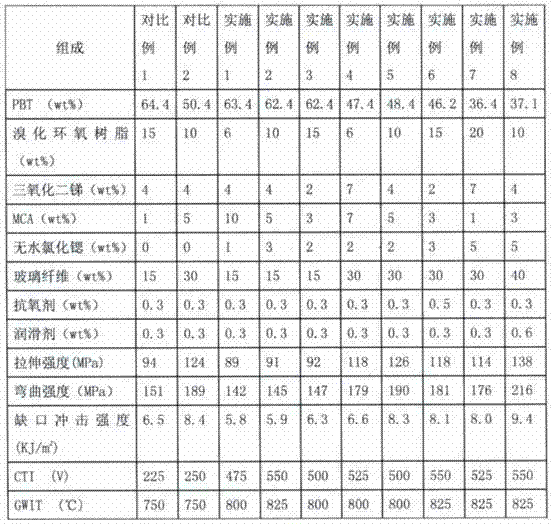

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment, the present invention is described in further detail. The examples are only used to explain the invention in detail, and should not be construed as limiting the protection scope of the present invention.

[0023] Raw material kind is selected as follows in embodiment and comparative example:

[0024] The grade of PBT resin is PBT 1100-211M, the relative density is 1.31, the melting point is 222±2°C, and the intrinsic viscosity is 1.0dl / g. It is a product of Taiwan Changchun Group; the brominated flame retardant is brominated epoxy resin, grade CXB-2000H, The product of South Korea Yujin; the synergistic flame retardant is dusty antimony white (antimony trioxide), a product of Anhua Huayu Antimony Industry Co., Ltd. in Hunan Province; the nitrogen-containing compound is melamine cyanurate, brand MCA, Sichuan Fine Chemicals Research and Design Institute products; strontium chloride anhydrous strontium chloride, Chongqing Xianfeng Str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com