Pure battery box of electric automobile suitable for replacing battery mode

A pure electric vehicle and battery mode technology, applied in the field of pure electric vehicle battery boxes, can solve the problems of difficult loading and unloading, various types, and inconsistent specifications, and achieve the effects of convenient loading and unloading, avoiding impact, and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

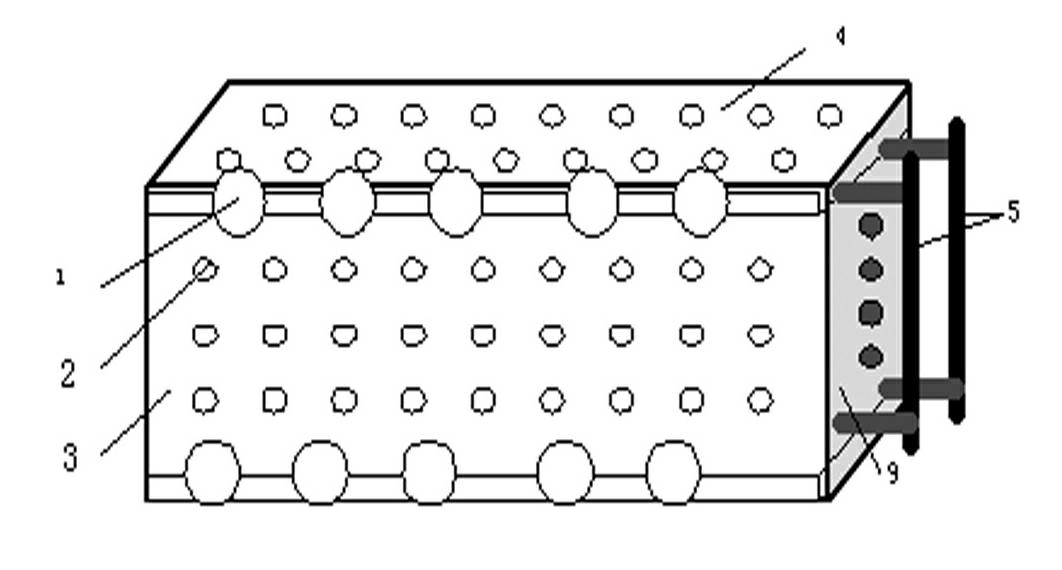

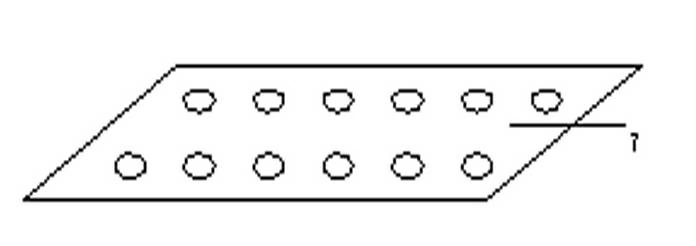

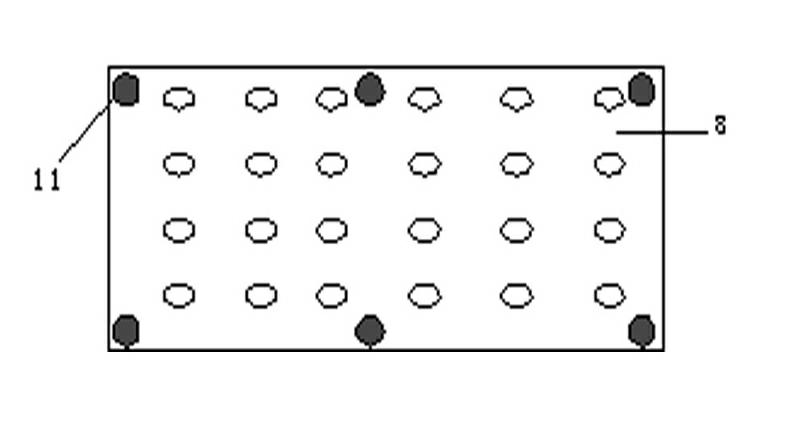

[0024] 1. Group configuration of pure battery car batteries

[0025] Generally, the power battery pack is composed of multiple 12 V or 24 V batteries in series. In order to be installed in different positions of the EV, the power battery pack is usually divided into multiple small battery packs and arranged in a scattered manner, which is beneficial to The mechanized installation, disassembly and maintenance of the battery pack is not conducive to the rapid replacement of the battery pack and hinders the large-scale commercial development of pure electric vehicles. In the present invention, the battery of the electric vehicle is configured, which consists of the following parts:

[0026] 1. Active power battery pack: a power battery pack formed by multiple 12 V or 24 V batteries in series, with a total voltage of 90-400 V, which is the main source of power for pure electric vehicles during driving, and is charged by a professional charging station. It can be quickly replaced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com