Green fleece washing method

A velvet washing and green technology, applied in the field of green velvet washing, can solve the problems of negative impact on human skin ecological environment, increase the difficulty of washing cost and process, increase the strength of fiber damage and energy consumption, and accelerate the pace of industrial upgrading. , The effect of improving the anti-pilling level and reducing the emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: adopt the mode of continuous addition of low-temperature detergent

[0024] 1. Basic information

[0025] (1) Model: 120;

[0026] (2) Raw materials: velvet or wool with an oil content of 6.12%;

[0027] (3) Driving speed: 450kg / hour;

[0028] (4) Net driving time per shift: 9 hours;

[0029] (5) Cleaning rate: 65%;

[0030] (6) Net velvet (hair): 2600kg;

[0031] (7) Use of detergent: low-temperature detergent (RC), the dosage is 30kg per ton of net (velvet) wool, and 78kg in total.

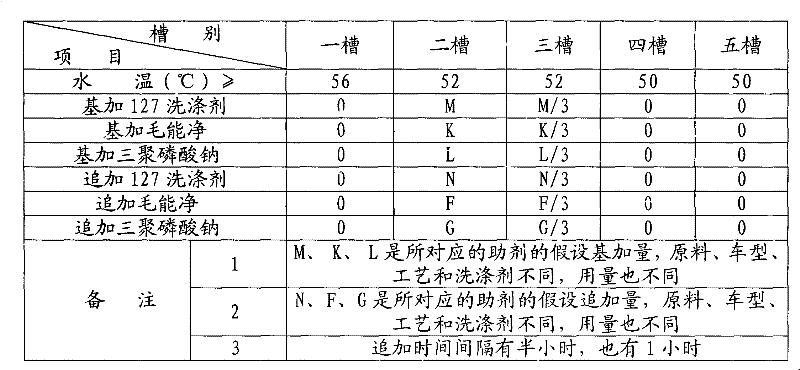

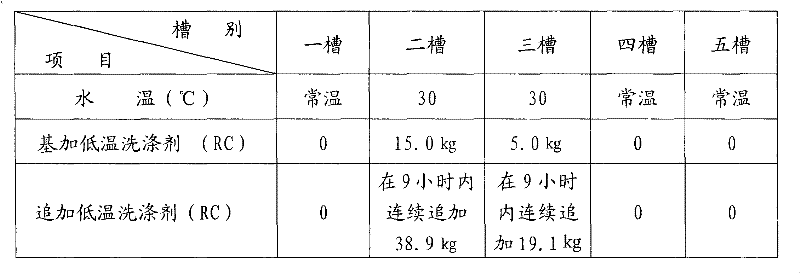

[0032] 2. Process

[0033]

[0034] 3. Description

[0035] (1) Put the lotion into the tank that should be added 20 minutes before driving, and turn on the circulation to fully dissolve;

[0036] (2) The starting point of timing starts when the down (hair) just enters the second slot;

[0037] (3) The detergent is continuously added by means of funnel or computer control;

[0038] (4) The first tank is running water after two hours of driving, and the fourth an...

Embodiment 2

[0045] Embodiment 2: adopt the mode of low-temperature detergent to add intermittently

[0046] 1. Basic information

[0047] (1) Model: 120;

[0048] (2) Raw materials: velvet or wool with an oil content of 6.12%;

[0049] (3) Driving speed: 450kg / hour;

[0050] (4) Net driving time per shift: 9 hours;

[0051] (5) Cleaning rate: 65%;

[0052] (6) Net velvet (hair): 2600kg;

[0053] (7) Use detergent: low-temperature detergent (RC), the dosage is 30kg per ton of clean cashmere (hair), 78kg in total.

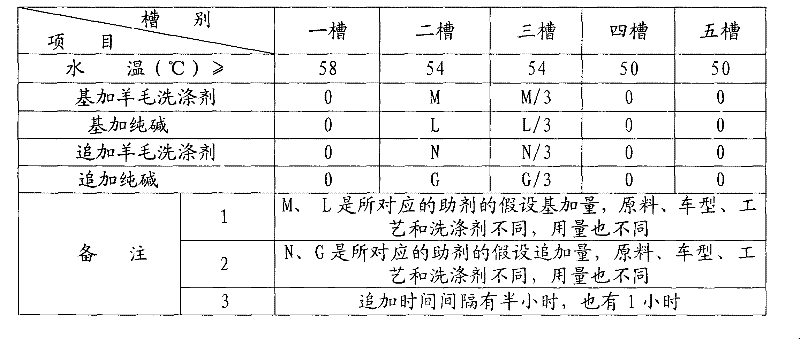

[0054] 2. Process

[0055]

[0056] 3. Description

[0057] (1) Put the lotion into the tank that should be added 20 minutes before driving, and turn on the circulation to fully dissolve;

[0058] (2) The starting point of timing starts when the down (hair) just enters the second slot;

[0059] (3) Detergent is added once every half hour. In this example, a total of 17 times is added; 2.0kg is added every half hour for the first 10 times of the second tank, 2.7kg is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com