Polyurethane porous membrane as well as preparation method and application thereof

A technology of polyurethane and porous film, applied in the field of polyurethane porous film and its preparation, can solve the problems of high requirements, high film density, poor moisture permeability, etc., achieve high moisture absorption performance, promote healing, and prevent drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, the preparation method of hydrophilic polyurethane medical dressing

[0022] Weigh 12 grams of polyurethane in a 500 mL plastic container, add 88 grams of DMF (dimethylformamide) and seal the container, shake and stir sufficiently and place it at room temperature for 24 hours to fully dissolve the polyurethane. After adding 0, 1.5, 3.0, 6.0, 12.0 grams of powdered cross-linked CMC (sodium carboxymethyl cellulose) respectively in five parts of dissolved polyurethane solutions, fully stir with a stirrer to disperse the CMC particles in the polyurethane solution. Put the above solution into a 20cm×30cm flat-bottomed plastic container, and after the solution is evenly distributed in the container, slowly add 300mL of a mixed solution of ethanol and water with a volume ratio of 50 / 50 on the surface of the solution to solidify the polyurethane into a porous film. 2 hours (or appropriate time) to fully solidify the membrane, remove the liquid part, and then impre...

Embodiment 2

[0023] Embodiment 2, the test method of hygroscopicity

[0024] At present, the method commonly used in the world to test the hygroscopicity of wound dressings is the method formulated by the British Pharmacopoeia for alginic acid medical dressings. In this method, the dressing was first cut into 5cmx5cm size, and then placed at 20°C and 65% relative humidity for 24 hours to allow the moisture regain of the dressing to reach equilibrium. At this time, the dry weight of the dressing was measured as W g. Then place the dressing in solution A that is 40 times heavier than itself, place it in a petri dish with a diameter of 90 mm at 37°C for 30 minutes, hold a corner of the dressing gauze with tweezers and hang it in the air for 30 seconds before measuring The wet weight of the dressing (W 1 ). Hygroscopicity of dressing per unit weight = (W 1 -W) / Wg.g -1 , and the hygroscopicity per unit area=4(W 1 -W)g.100cm -2 .

[0025] Solution A can be composed of 8.3 grams of NaCl, ...

Embodiment 3

[0026] Embodiment 3, the hygroscopic performance of hydrophilic polyurethane medical dressing

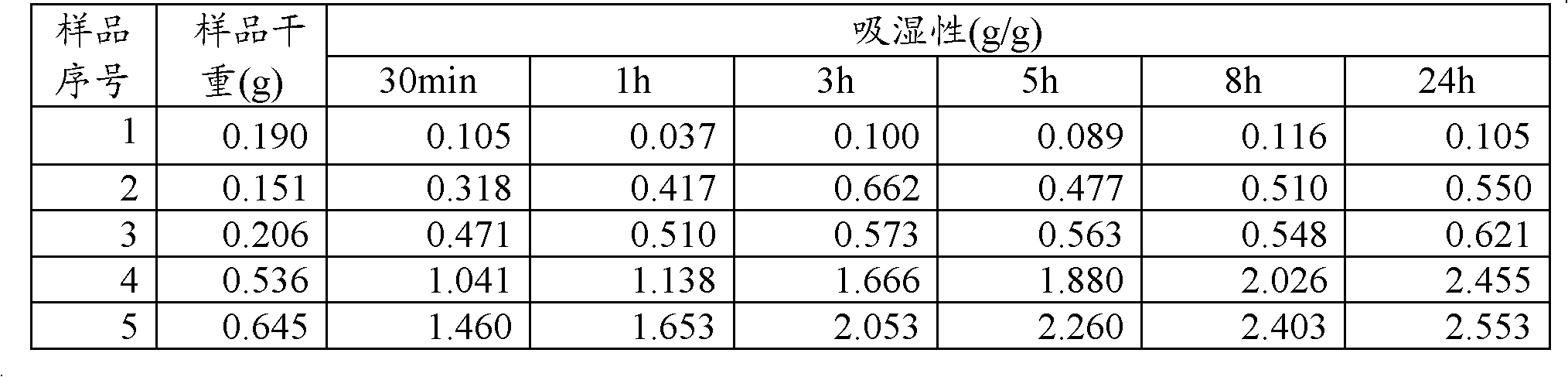

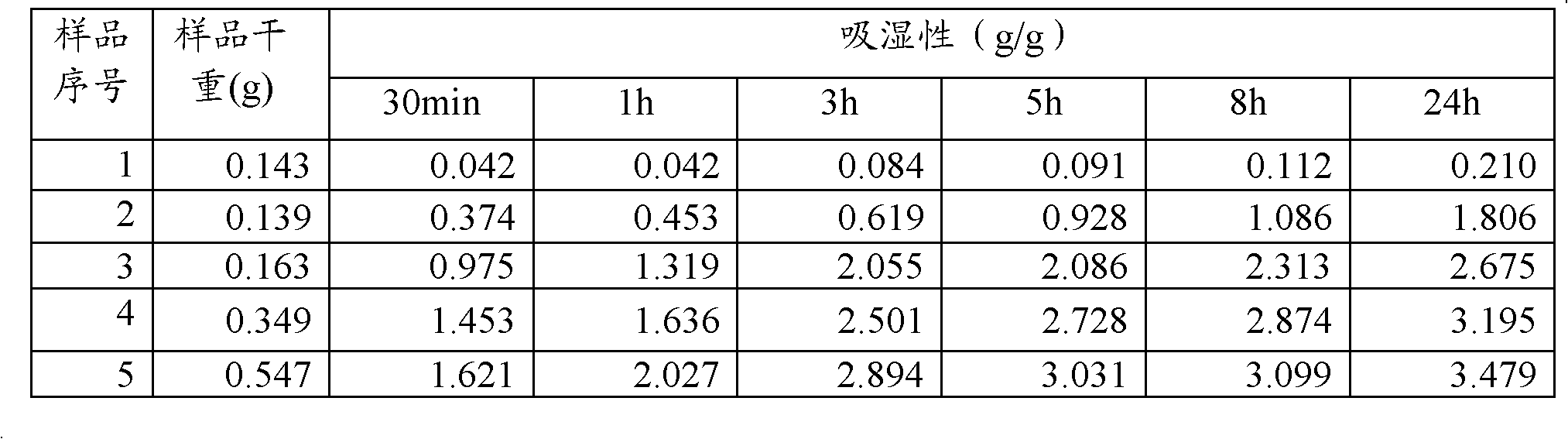

[0027] With the five samples obtained in Example 1, according to the test method in Example 2, respectively adopt A solution and deionized water to test the hygroscopicity of five samples, wherein crosslinked in samples 1, 2, 3, 4, 5 The amounts of CMC added were 0, 1.5g, 3.0g, 6.0g, and 12.0g, respectively. The results in Table 1 and Table 2 show that the addition of cross-linked CMC can significantly improve the hygroscopicity of polyurethane dressings.

[0028] Table 1. Hygroscopicity of PU films containing different amounts of cross-linked CMC in solution A

[0029]

[0030] Table 2. Hygroscopicity of PU films containing different amounts of cross-linked CMC in deionized water

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com