Method for recycling garbage plastics and special equipment

A technology for plastics and garbage, applied in the field of recycling and recycling of garbage plastics, to achieve the effect of less environmental pollution and simple process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

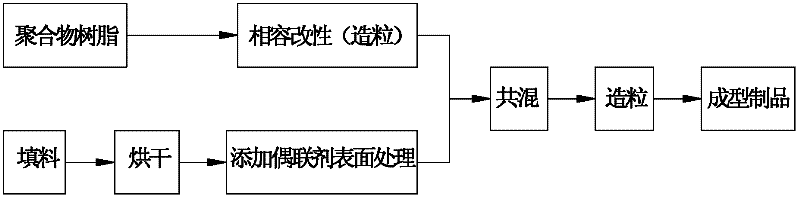

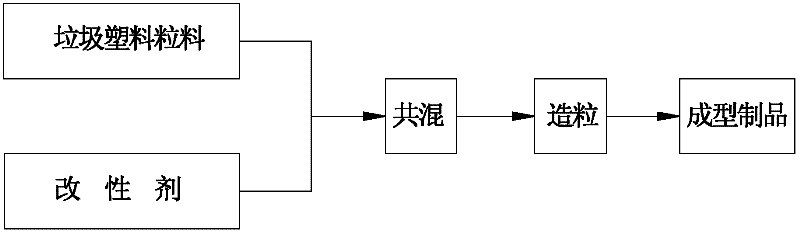

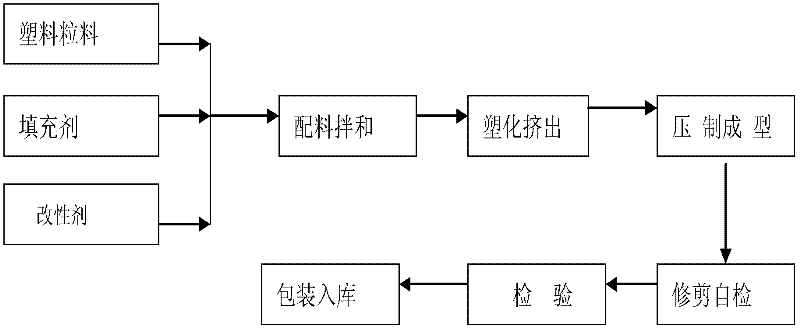

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, the garbage plastic sorting and rough processing process of the present invention includes plastics and impurities separation, plastic air-drying, granulation and other processes; the garbage plastic raw materials are first sent to the crushing equipment to be broken into flakes, and then the broken Garbage plastic flakes are fed into the winnowing equipment, and the plastic flakes and impurities in them are propulsed with the spiral of hot air flow, because vibration will be generated during the propulsion process, and due to the density difference between plastics and impurities, the plastics and impurities are completely separated And fall in different positions to select plastic flakes and remove impurities. At the same time, due to the accelerated vaporization of water under the action of hot air, the dry and clean plastic flakes selected by wind are sent to granulation equipment to make reusable particles. The crushing equipment, winnowing equipment ...

Embodiment 2

[0023] Embodiment 2, the control system of the present invention is connected with feeding conveying device, crushing device, winnowing equipment, impurity removing device and granulation equipment respectively; Utilize the principle of belt conveyor to sort out the waste dump under the control of computer Garbage plastics are sent to the crushing system. By measuring the content of moisture and impurities, the computer controls the speed of the conveyor belt to ensure uniform feeding and drying of the flakes; the sawtooth-shaped rotating blade is used to tear the garbage plastics, The film is made into flakes, and the flakes are sent to the drying system by the blower. Because the density of the plastic flakes and impurities is different, the flakes with low density are sent out, and the impurities with higher density fall into the impurity removal system to achieve crushing and the first The second impurity removal process; the heat generated by the hot air stove is used to c...

Embodiment 3

[0024] Embodiment 3, the special equipment used in the washing-free recovery method of garbage plastics according to the present invention includes feeding conveying device, crushing device, winnowing equipment, impurity removing device, granulating equipment, control system, and the control system is connected with feeding conveying device respectively , crushing device, air separation equipment, impurity removal device and granulation equipment are connected; the feeding conveying device adopts a belt conveyor, the crushing device adopts a sawtooth rotating blade, the air separation equipment includes a hot blast stove, a blower, and the impurity removal device includes air separation equipment At the bottom of the chamber, the granulation equipment includes a screw feeding device, a vibrating device and a granulation device installed on the feeding port; the control system includes an industrial computer and an induction device; a heating device can also be installed at the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com