Pitavastatin calcium lipid solid preparation

A technology of pitavastatin calcium and solid preparation, applied in the field of medicine, can solve problems such as increasing drug retention time, and achieve the effects of improving medication compliance, improving quality and improving curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Example 1 Preparation of Pitavastatin Calcium Liposome Tablets

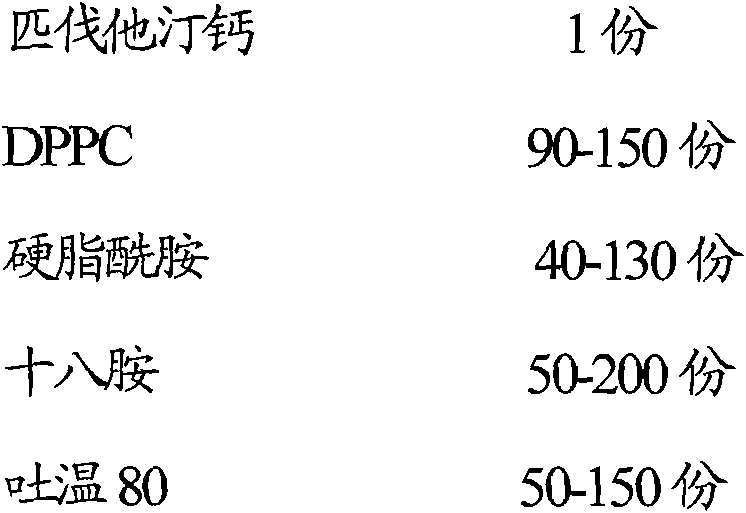

[0066] The raw and auxiliary materials used are as follows:

[0067]

[0068]

[0069] Adopt the following production process to prepare pitavastatin calcium liposome tablet:

[0070] (a) Dissolve 150g DPPC, 50g stearylamide, 200g octadecylamine and 50g Tween 80 in a mixed solvent of ethanol and chloroform with a volume ratio of 5:1 in 1000ml, mix well, and depressurize at 45°C on a rotary evaporator Remove ethanol and chloroform to obtain a phospholipid film;

[0071] (b) Add 1000ml of pH 6.8 phosphate buffer solution, oscillate and stir to completely hydrate the phospholipid membrane, homogeneously emulsify at 500rpm, and filter through a 0.45 μm microporous membrane to obtain a blank liposome suspension;

[0072] (c) 1 g of pitavastatin calcium was dissolved in blank liposome suspension, filtered through a 0.45 μm microporous membrane, kept at 50° C. for 30 minutes, and spray-dried to obtain l...

Embodiment 2

[0075] The preparation of embodiment 2 pitavastatin calcium liposome sheet

[0076] The raw and auxiliary materials used are as follows:

[0077]

[0078] Adopt the following production process to prepare pitavastatin calcium liposome tablet:

[0079] (a) Dissolve 150g DPPC, 100g stearylamide, 50g octadecylamine and 150g Tween 80 in 1200ml of a mixed solvent of ethanol and chloroform with a volume ratio of 5:1, mix well, and depressurize at 45°C on a rotary evaporator Remove ethanol and chloroform to obtain a phospholipid film;

[0080] (b) Add 1200ml of phosphate buffer solution with a pH of 6.8, oscillate and stir to completely hydrate the phospholipid membrane, homogeneously emulsify at 5000rpm, and filter through a 0.45 μm microporous membrane to obtain a blank liposome suspension;

[0081] (c) 1 g of pitavastatin calcium was dissolved in blank liposome suspension, filtered through a 0.45 μm microporous membrane, kept at 50° C. for 50 minutes, and spray-dried to obtai...

Embodiment 3

[0084] The preparation of embodiment 3 pitavastatin calcium liposome sheet

[0085] The raw and auxiliary materials used are as follows:

[0086]

[0087] Adopt the following production process to prepare pitavastatin calcium liposome tablet:

[0088](a) 180g DPPC, 80g stearylamide, 130g octadecylamine and 140g Tween 80 are dissolved in 1500ml of a mixed solvent of ethanol and chloroform with a volume ratio of 5:1, mix well, and reduce the temperature at 45°C on a rotary evaporator. Ethanol and chloroform were removed by pressure to obtain a phospholipid film;

[0089] (b) Add 1500ml of pH 6.8 phosphate buffer solution, oscillate and stir to hydrate the phospholipid membrane completely, homogeneously emulsify at 5000rpm, and filter through a 0.45 μm microporous membrane to obtain a blank liposome suspension;

[0090] (c) 2 g of pitavastatin calcium was dissolved in blank liposome suspension, filtered through a 0.45 μm microporous membrane, kept at 50° C. for 40 minutes, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com