Continuous slagging and pressure relief device for pressurized gasifier

A technology of pressurized gasification and pressure relief device, applied in the direction of granular/powder fuel gasification, etc., can solve the problems of waste of resources and energy, high operating costs, complex structure, etc., to protect the environment, improve work efficiency, change Effects of working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

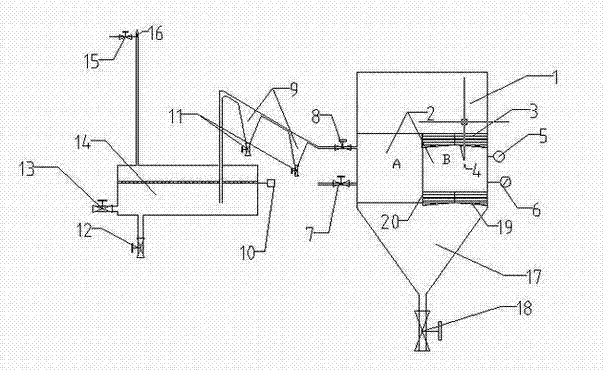

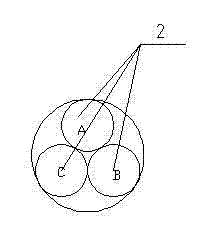

[0024] 1. As attached figure 1 As shown, before the gasifier 1 works, first ensure that all valves are in the closed state. The gasifier 1 starts to work, and the upper flap valve 4 is opened. After a certain time delay, the upper flap valve 3 is opened, and the slag starts to flow from the gasifier 1 falls into the slag discharge tank 2, and the material level gauge 5 starts to work at the same time, when the slag in the slag discharge tank 2 reaches the height set by the material level gauge 5, the upper flap valve 3 is automatically closed, and then the upper flap valve 4 is closed .

[0025] 2. Then open the pressure relief valve 8, harmful gas and powder enter the pressure relief and dust removal unit, initially remove the toxic gas in the slag discharge tank, then open the purge valve 7, fill the flue gas, and discharge the residual toxic gas in the slag, Part of the discharged dust lands at the ash hopper 9, and the ash hopper 9 collects it, and the rest of the dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com