A kind of method for preparing mesoporous silica

A mesoporous silica and silicon source technology, applied in the direction of silica, silicon oxide, etc., can solve the problems of potential safety hazards, low solvent volatilization efficiency, environmental pollution, etc., achieve mild reaction conditions, facilitate large-scale production, Simple and efficient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

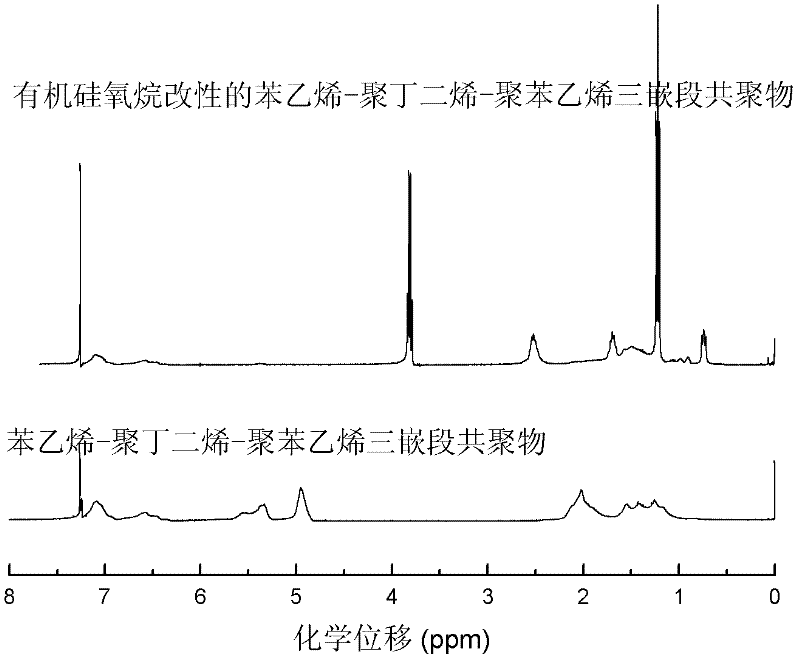

[0037] (1) Dissolve 1g of styrene-butadiene-styrene triblock copolymer and 24.79g of mercaptopropyltriethoxysilane in 48mL of dioxane, and stir evenly at 10-45°C; then Add 0.17 g of azobisisobutyronitrile and disperse evenly, then gradually raise the temperature to 60°C and react for 1 day. After precipitation, suction filtration and drying, an organosiloxane-modified styrene-butadiene-styrene triblock copolymer is obtained;

[0038] (2) Dissolve 0.2010g of organosiloxane-modified styrene-butadiene-styrene triblock copolymer and 1.8015g of ethyl orthosilicate in 5mL of tetrahydrofuran in a closed container at 10-45°C and stirring constantly, then add 0.6544g deionized water and 0.6568g 1M hydrochloric acid drop by drop, along with the carrying out of stirring, the generation of sol-gel reaction makes the system viscosity rise gradually; Stop stirring after about 25 minutes, keep the reactor 10 It was sealed at -45°C for 14 days; then it was degraded at high temperature in a t...

Embodiment 2

[0040] (1) Dissolve 1g of styrene-butadiene-styrene triblock copolymer and 24.79g of mercaptopropyltriethoxysilane in 48mL of dioxane, and stir evenly at 10-45°C; then Add 0.17 g of azobisisobutyronitrile and disperse evenly, then gradually raise the temperature to 60°C and react for 1 day. After precipitation, suction filtration and drying, an organosiloxane-modified styrene-butadiene-styrene triblock copolymer is obtained;

[0041] (2) Dissolve 0.4002g of organosiloxane-modified styrene-butadiene-styrene triblock copolymer and 1.6039g of ethyl orthosilicate in 5mL of tetrahydrofuran in a closed container at 10-45°C and stirring continuously, then add 0.6175g deionized water and 0.6300g 1M hydrochloric acid drop by drop, along with the carrying out of stirring, the occurrence of sol-gel reaction makes the viscosity of the system gradually increase; stop stirring after about 15 minutes, keep the reactor for 10 It was sealed at -45°C for 14 days; then it was degraded at high t...

Embodiment 3

[0043] (1) Dissolve 1g of styrene-butadiene-styrene triblock copolymer and 24.79g of mercaptopropyltriethoxysilane in 48mL of dioxane, and stir evenly at 10-45°C; then Add 0.17 g of azobisisobutyronitrile and disperse evenly, then gradually raise the temperature to 60°C and react for 1 day. After precipitation, suction filtration and drying, an organosiloxane-modified styrene-butadiene-styrene triblock copolymer is obtained;

[0044] (2) Dissolve 0.6024g of organosiloxane-modified styrene-butadiene-styrene triblock copolymer and 1.4080g of ethyl orthosilicate in 5mL of tetrahydrofuran in a closed container at 10-45°C and stirring constantly, then add 0.5807g deionized water and 0.5764g 1M hydrochloric acid dropwise, along with the carrying out of stirring, the occurrence of sol-gel reaction makes the viscosity of the system gradually increase; stop stirring after about 8 minutes, keep the reactor for 10 It was sealed at -45°C for 14 days; then it was degraded at high temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com