Impact-resistant packaging sheet and its preparation method

A packaging sheet and impact-resistant technology, applied in the field of impact-resistant packaging sheet and its preparation, can solve the problems of material brittleness and impact resistance, poor water resistance, material cracking, etc., and achieve good impact resistance, smooth surface, phase Good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

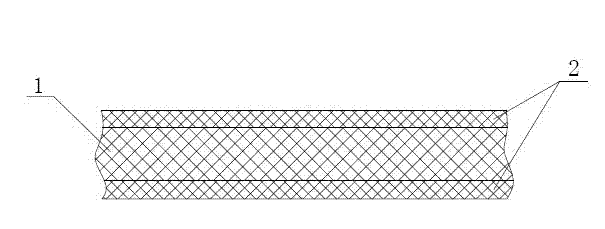

[0013] according to figure 1 As shown, the impact-resistant packaging sheet of the present invention is composed of an amorphous polyethylene terephthalate APET substrate layer 1 and surface layers 2 on both sides of the substrate layer. Amorphous polyethylene terephthalate APET has an intrinsic viscosity of 0.810±0.02 dL / g and a weight of 90kg. The surface layer 2 is composed of the following components: polyethylene terephthalate-1,4-cyclohexanedimethanol PETG resin 9kg, RTC103 smooth masterbatch 0.05kg, antistatic agent glyceryl monostearate 0.1kg, auxiliary agent dispersant polyethylene wax 0.85kg. The antistatic agent can be 2-hydroxyethyl alkylamine or octyl polyoxyethylene ether. Auxiliary dispersant can be oxidized polyethylene wax.

[0014] The preparation method of the impact-resistant packaging sheet above is to pre-crystallize the weighed non-crystallized polyethylene terephthalate APET at 115°C for 1.5 hours, then dry at 175°C for 3 hours, and then weigh Good ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com