Preparation and application of hierarchical mesoporous γ-al2o3 nanostructured adsorbent

A nanostructure and adsorbent technology, applied in solid adsorbent liquid separation, separation methods, other chemical processes, etc., can solve problems such as product application performance that is not mentioned, and achieve controllable morphology, strong adsorption performance, and mild conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Sorbent provided by the invention, its preparation method comprises the following steps:

[0030] 1. Dissolve one of aluminum sulfate, aluminum chloride, aluminum nitrate, aluminum ammonium sulfate and aluminum potassium sulfate or a mixture of any proportion in distilled water, then add thiourea, stir evenly to form Al 3+ The concentration is 0.01~0.5 mol / L, thiourea and Al 3+ The molar ratio is 1.0~25.0:1.0, then it is transferred to a hydrothermal kettle, and reacted at 130~200 °C for 2~24 h to obtain a hydrothermal product;

[0031] 2. After the hydrothermal product is cooled and filtered, it is first washed with distilled water until neutral, then the neutral filter cake is dispersed and washed with absolute ethanol and filtered, and the obtained filter cake is vacuum-dried at 60-100 °C for 4-16 h Finally, alumina precursor powder is obtained;

[0032] 3. The vacuum-dried product was calcined in a static air atmosphere at 450-700 °C for 2-6 h to prepare hierarchi...

Embodiment 1

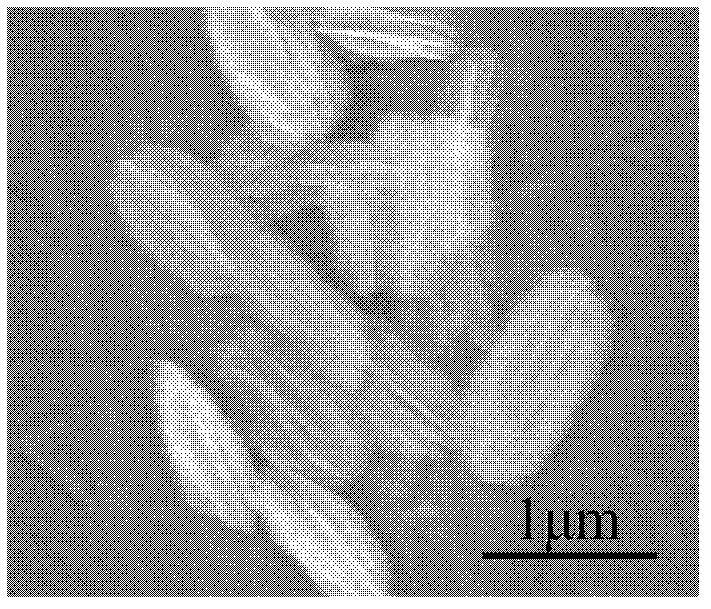

[0037] Weigh a certain amount of aluminum chloride and thiourea respectively, mix and dissolve them in 70 mL distilled water, and stir evenly to form Al 3+ concentration of 0.1 mol / L, thiourea and Al 3+ The mixed solution with a molar ratio of 10.0:1.0 was then transferred to a hydrothermal kettle and reacted for 3 h under closed hydrothermal conditions at 180 °C. The hydrothermal product was sequentially cooled, filtered, dispersed and washed with a small amount of absolute ethanol, filtered, and then vacuum-dried at 80 °C for 12 h. The obtained sample was analyzed by XRD to be pure pseudo-boehmite phase. Then, the temperature was programmed to 550 °C at a heating rate of 1.5 °C / min, and roasted for 4 h under a static air atmosphere to obtain a product whose morphology and structure were stacked by irregular nano-sheets, see figure 1 , analyzed by XRD as pure γ-Al 2 o 3 Mutually. Its specific surface area and pore volume are 145.4 m 2 / g and 0.20 cm 3 / g, the pore diame...

Embodiment 2

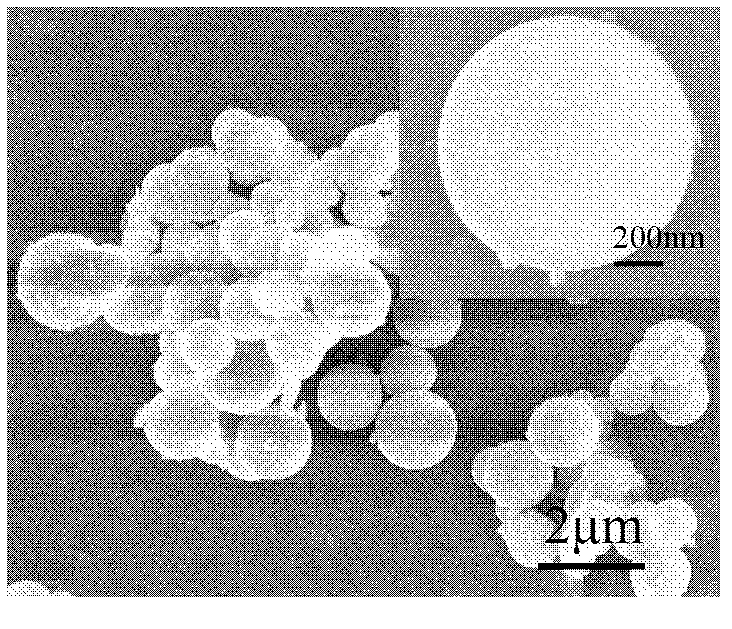

[0041] Weigh a certain amount of aluminum nitrate, potassium aluminum sulfate, and thiourea respectively, mix and dissolve them in 70 ml distilled water, and stir evenly to form Al 3+ The concentration is 0.05 mol / L (among them, aluminum nitrate, aluminum potassium sulfate 3+ The contribution of concentration is 0.025 and 0.025 mol / L), thiourea and Al 3+ The mixed solution with a molar ratio of 4.0:1.0 was then transferred to a hydrothermal kettle and reacted for 3 h under closed hydrothermal conditions at 180 °C. The hydrothermal product was sequentially cooled, filtered, dispersed and washed with absolute ethanol, filtered, and then vacuum-dried at 60 °C for 16 h. The obtained sample was analyzed by XRD to be pure pseudo-boehmite phase. Then the temperature was programmed to 450 °C at a heating rate of 1.5 °C / min, and roasted for 6 h under a static air atmosphere to obtain spindle-shaped particles whose morphology was assembled from nano-sheets, see figure 2 , analyzed by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com