Preparation method of printed circuit board with metal micro heat sink

A technology for printed circuit boards and heat sinks, which is applied in the field of preparation of printed circuit boards, and can solve problems such as limited heat transfer capacity and low heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

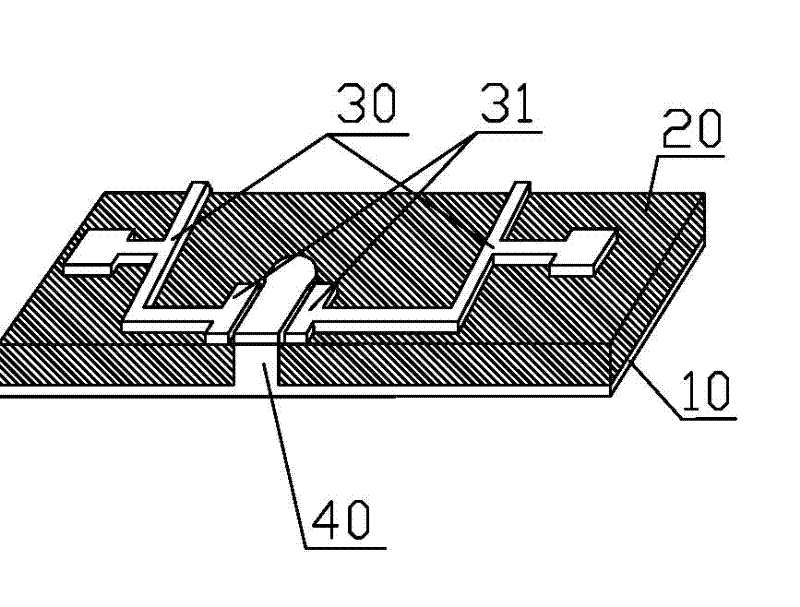

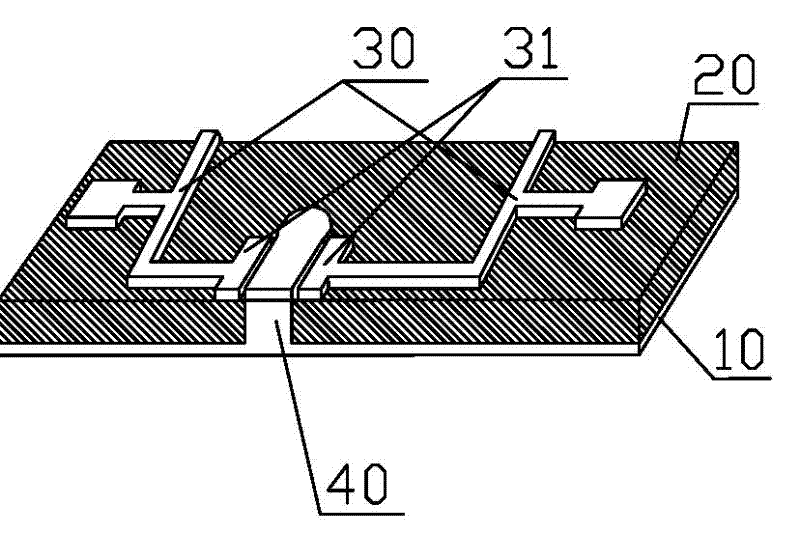

[0036] figure 1 A kind of preferred embodiment of the preparation method of shown printed circuit board with metal micro radiator comprises the following steps:

[0037] S1, prepare an integrally formed metal layer, the metal layer includes a metal bottom layer 10 and one or more protrusions of columnar structures located on one surface of the metal bottom layer, the metal bottom layer is the metal bottom layer 10 of the printed circuit board, The one or more protruding parts are metal micro radiators 40;

[0038] S2. Provide a single-sided or double-sided copper-clad insulating board, which is cut into a printed circuit board according to the predetermined size, and adopts the method of hole metallization and pattern transfer of the traditional printed circuit board on the first layer of the copper-clad insulating board. Metallized holes (not shown in the figure) and copper layer lines 30 of conventional printed circuit boards are made on the copper surface, that is, insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com