An axial pneumatic drive planetary rotating device

A planetary rotation and pneumatic technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as stuck, unstable transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

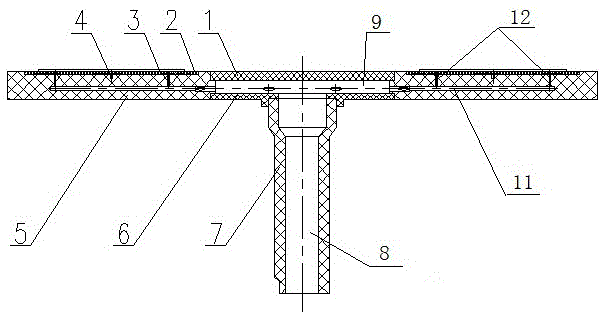

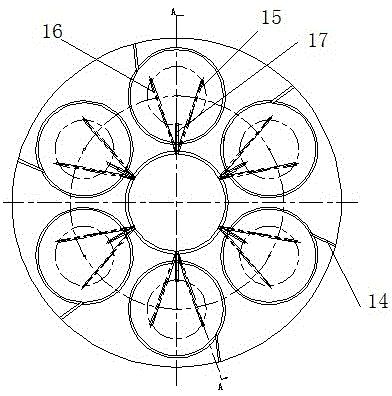

[0018] Such as figure 1 , figure 2 As shown, an axial pneumatically driven planetary rotation device includes an autorotation disk 5 that drives the substrate 3 to rotate. The center of the bottom surface of the autorotation disk 5 is equipped with a hollow shaft 7 with a vent hole 8 inside. The inner center of the rotation disk 5 is provided with There is a main air hole 9 communicated with the air hole 8 of the hollow shaft 7, and the radial center of the main air hole 9 coincides with the center line of the minute air hole 11 of the rotating disk 5; as image 3 , Figure 4 As shown, the top surface of the rotation disk 5 is provided with a plurality of planetary disk grooves 10 arranged along the circumference, and the top surface of the rotation disk 5 is provided with an air guide groove 14 communicating with the planetary disk grooves 10 near the outer periphery of the rotation disk 5, and The planetary disk 2 is installed in the planetary disk groove 10, and the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com