Test tube uncapping machine and uncapping method thereof

A test tube and cap opening device technology, which is applied in the field of scientific research equipment, can solve the problems of increasing the risk of infection and increasing cross-contamination between test tubes, and achieve the effect of reducing the risk of infection and avoiding cross-infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

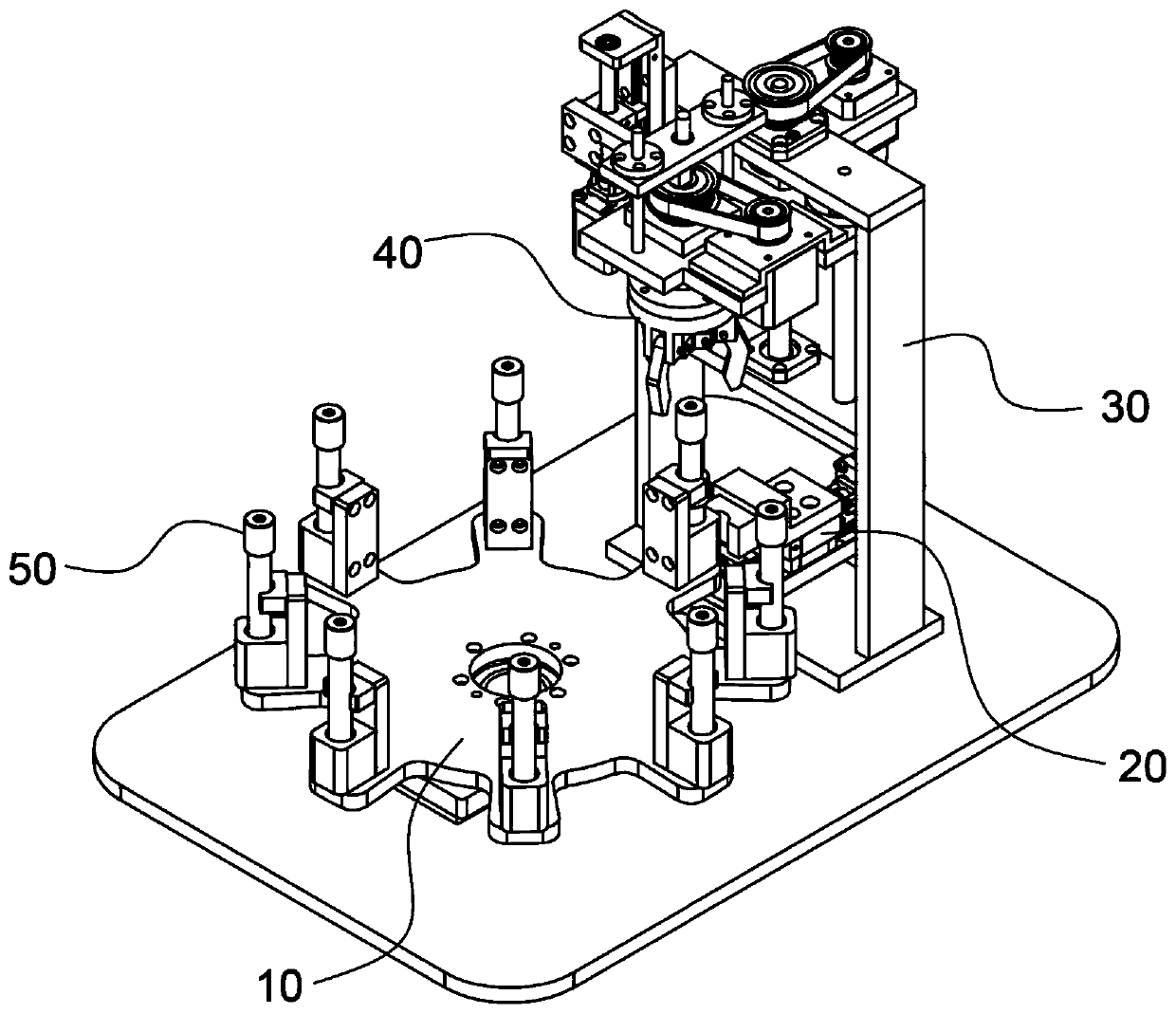

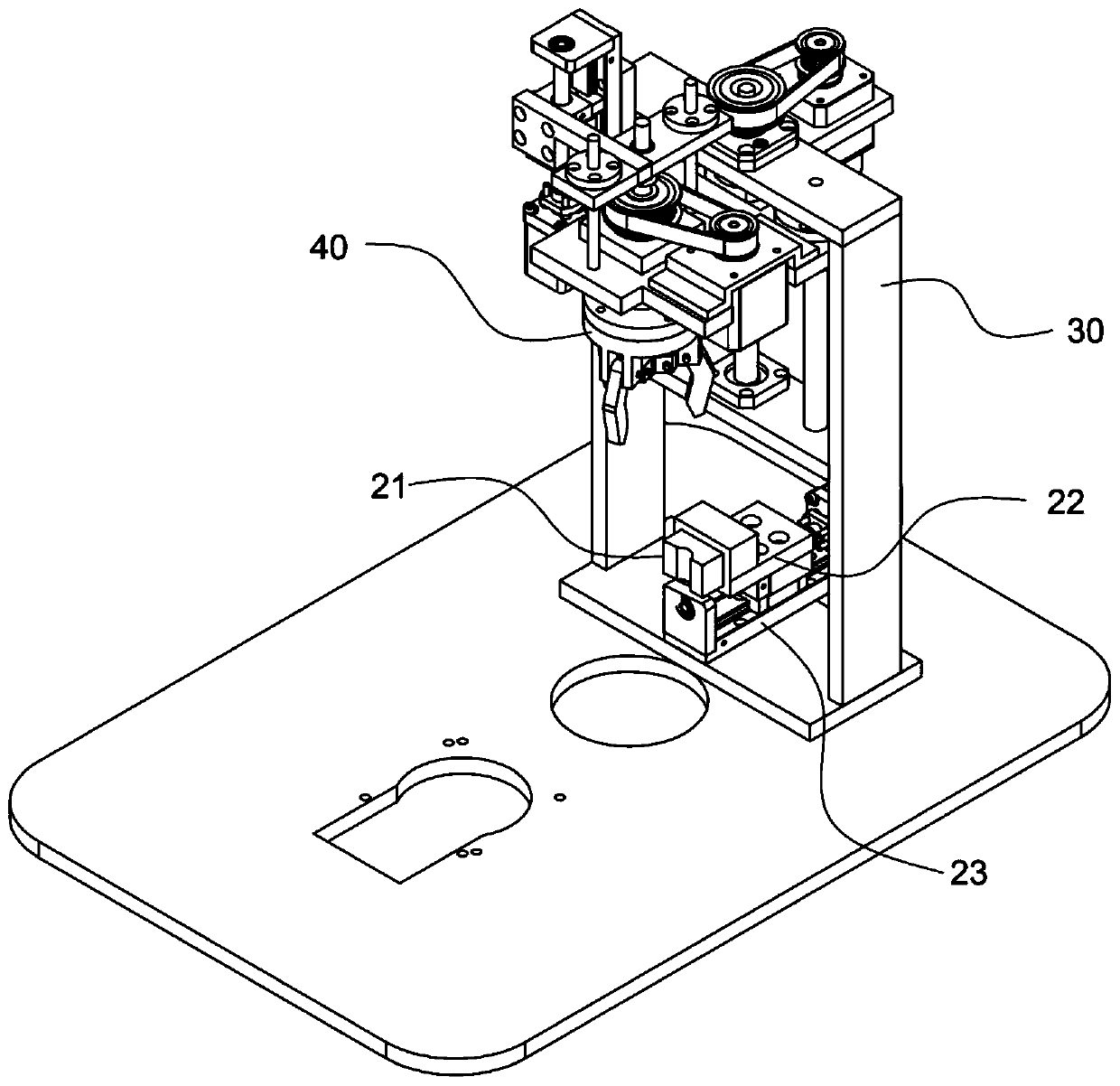

[0048] Such as figure 1 , figure 2 , image 3 and Figure 6 As shown, a test tube uncapping machine includes a test tube 50 provided with an end cap, and also includes a turntable device 10, a clamping device 20, a lifting device 30 and a cap uncapping device 40;

[0049]Wherein the turntable device 10 includes a turntable 12 and a test tube holder 13, the turntable 12 is disc-shaped, and eight support ears are evenly arranged on the circumference of the turntable 12, and each support ear is an "n"-shaped square, and the thickness of the support ears is Equal to the thickness of the turntable 12, a test tube holder 13 is fixed above each support ear, the bottom of the test tube 50 is placed in the test tube holder 13, and the length direction of the test tube 50 is consistent with the axis direction of the turntable 12;

[0050] Suppose, after the test tube 50 is placed, the end of the test tube 50 with the end cap is the upper side, and the bottom end of the test tube 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com