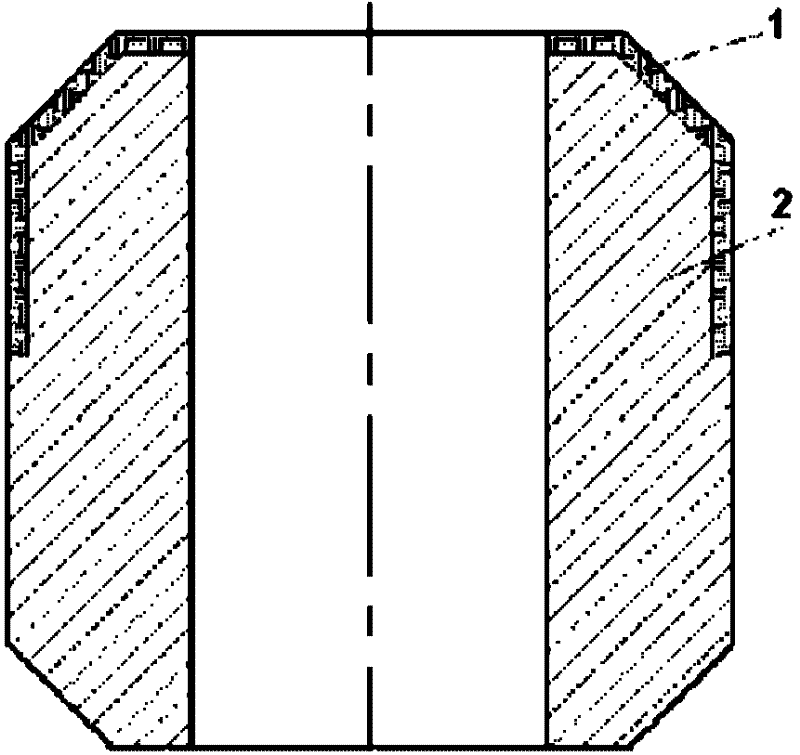

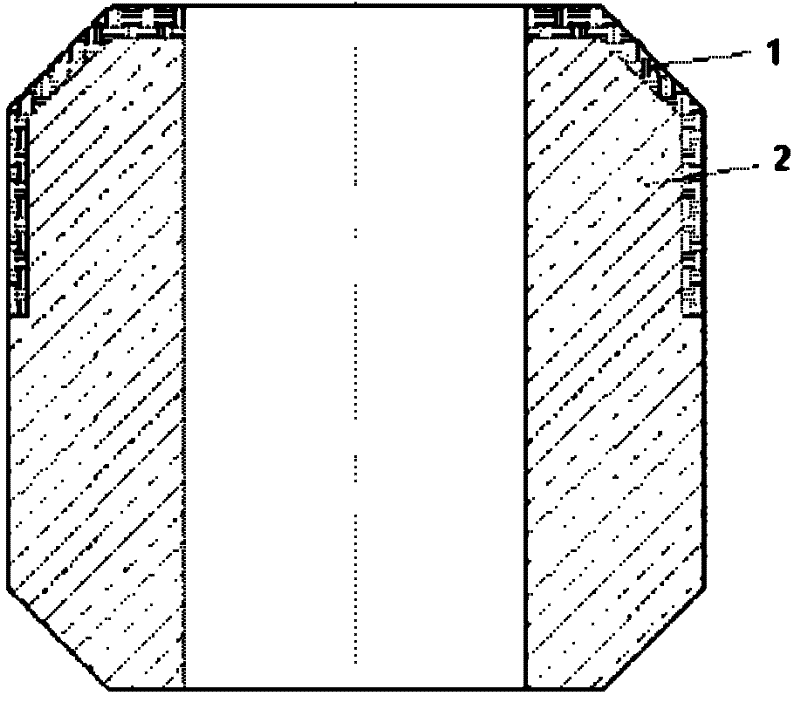

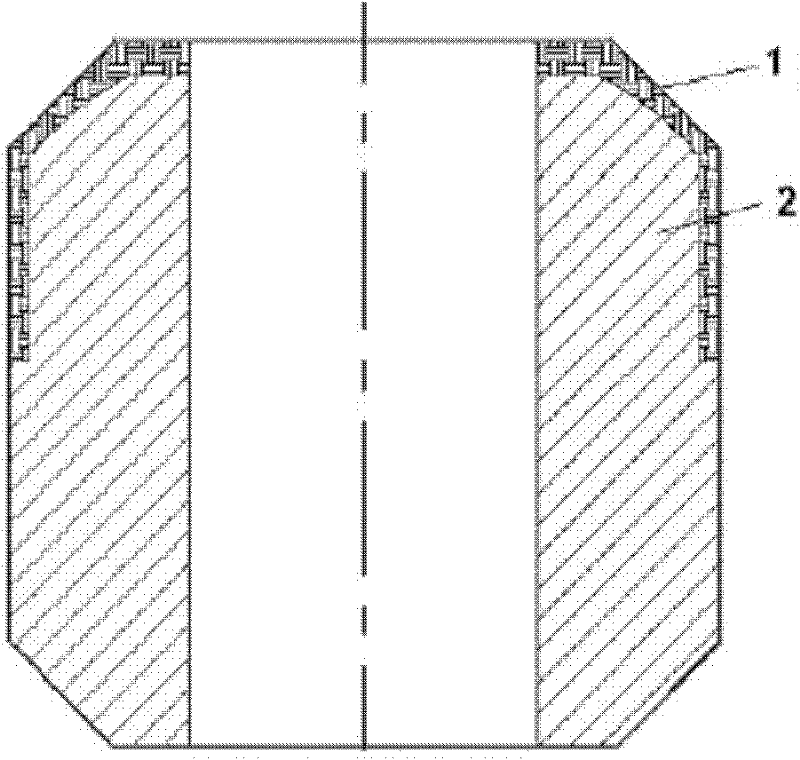

A compression packer rubber cartridge and its preparation method and application

A compression packer and rubber cartridge technology, used in sealing/isolation, other household appliances, applications, etc., can solve the problems of inconsistent shrinkage rate, poor compatibility of rubber cartridge substrates, and rubber cartridge seal failure, etc. Improve pressure bearing capacity and sealing effect, good ductility and elasticity, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the compression packer rubber cartridge of the present invention for example comprises the following steps:

[0020] (1) Preparation of rubber compound

[0021] The rubber compound used to prepare the main body and / or shoulder of the compression packer rubber cartridge of the present invention includes 100 parts by weight of rubber material, 30-90 parts by weight (preferably 40-85 parts by weight) of carbon black and / or white Carbon black and 1-10 parts by weight of crosslinking agent. Optionally, crosslinking accelerators, plasticizers, anti-aging agents, lubricants, mineral fillers, processing aids or mixtures thereof commonly used in the rubber field can also be added.

[0022] The above-mentioned cross-linking agent may be a cross-linking agent commonly used in the field of rubber, for example, including a free radical cross-linking agent or a redox cross-linking agent. Preferable examples include, for example, dicumyl peroxide, 2,5-dimet...

Embodiment 1

[0044] Get the raw materials ready according to the following formula (parts by weight): hydrogenated nitrile butadiene rubber 100 parts of C4369 (Lanxess Company), 85 parts of N550 carbon black (Cabot Company), 2.5 parts of stearic acid, 1.5 parts of antioxidant Naugard 445 (Chemtura Company), dicumyl peroxide (40% effective Components) 5.0 parts, 5.0 parts of cross-linking accelerator Pertac / GR (Kettlitz-Chemie, Germany), 10.0 parts of trioctyl trimellitate, 5.0 parts of zinc oxide; add the above raw materials into an open mill, and mix at 80°C Mix evenly to obtain hydrogenated nitrile rubber mix. Weigh 10Kg of the above-mentioned hydrogenated nitrile rubber compound, thin it to a thickness of 2mm, cut it into small pieces, put it into a 50L barrel, and add butyl acetate / methyl isobutyl ketone=50:50 mass ratio configuration Mix solvent 25Kg, start stirring, until the hydrogenated nitrile butadiene rubber mix dissolves evenly. The glue of gained concentration 28.5% is coat...

Embodiment 2

[0046] Get the raw materials ready according to the following formula (parts by weight): hydrogenated carboxylated nitrile rubber 100 parts of XT (Lanxess Corporation), 50 parts of N550 carbon black, 35 parts of white carbon black, 2.5 parts of stearic acid, 4451.5 parts of antioxidant Naugard, 7.0 parts of dicumyl peroxide (40% active ingredient), triene 1.5 parts of propyl isocyanurate, 5.0 parts of trioctyl trimellitate, and 5.0 parts of zinc oxide; put the above raw materials into an open mill, and mix them evenly at 80°C to obtain a hydrogenated carboxylated nitrile rubber compound . Weigh 10Kg of the above-mentioned hydrogenated nitrile rubber compound, thin it to a thickness of 2mm, cut it into small pieces, put it into a 50L barrel, and add butyl acetate / methyl isobutyl ketone=50:50 mass ratio configuration Mix 30Kg of solvent, start stirring until the hydrogenated nitrile rubber mix dissolves evenly. The glue of gained concentration 25.0% is coated on the area dens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com