A method for regulating the fermentation process of fumaric acid-producing Rhizopus

A fermentation process, fumarate technology, applied in the field of bioengineering to achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

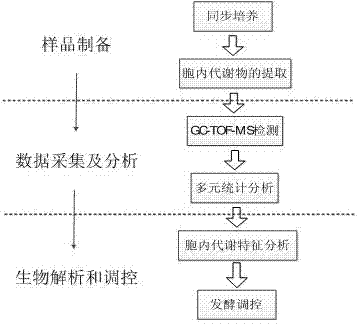

Method used

Image

Examples

Embodiment 1

[0030] This embodiment illustrates that fumarate-producing Rhizopus oryzae ( Rhizopus oryzae ) method for regulating the fermentation process.

[0031] Strains: (1) The original strain Rhizopus oryzae (ATCC 20344).

[0032] (2) High-yield fumaric acid mutant strains: the above-mentioned original strains were treated with a femtosecond laser with a wavelength of 800 nm and a repetition rate of 76 MHz under the conditions of an irradiation power of 5-40 mW and an irradiation time of 5-30 s. treatment, obtained a high-yield fumaric acid strain of Rhizopus oryzae; the optimized femtosecond laser mutagenesis method used therein comes from the patent publication number CN102061294A, and the name is "Femtosecond laser mutagenesis of Rhizopus oryzae for breeding fumaric acid high-yield strains method” patent application literature.

[0033] 1. Synchronously culture the above-mentioned original strain and the high-yielding mutant strain induced by femtosecond laser mutagenesis ...

Embodiment 2

[0039] This embodiment illustrates that fumaric acid-producing Rhizopus aureus ( Rhizopus arrhizus ) method for regulating the fermentation process.

[0040] Strains: (1) The original strain Rhizopus arrhizus (NRRL 2582).

[0041] (2) High-yield mutant strain of fumaric acid: the above-mentioned original strain was treated with a UV lamp with a power of 15 W, an irradiation distance of 30 cm, and an irradiation time of 50 s, and a strain of Rhizopus lessi with high yield and rich malic acid strain.

[0042] 1. Synchronously culture the high-yield mutant strain of Rhizopus alicifera and the original bacterial strain at 400 rpm, 35° C. of temperature, 10% inoculum size, and a 7 LNBS fermenter with a liquid filling capacity of 5 L (the composition of the fermentation medium and the mass content For: glucose 80 g, (NH 4 ) 2 SO 2 2 g, yeast extract (total nitrogen content 9.8%) 0.4 g, KH 2 PO 4 0.4 g, MgSO 4 ·7H 2 O 0.4 g, ZnSO 4 7H2O 0.05 g, FeSO 4 ·7H 2 O 0.01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com