Preparation method of high temperature resistant non-halogen fire resistant ultraviolet curing solder resist ink

A solder mask ink, flame retardant technology, applied in the direction of ink, printed circuit parts, household appliances, etc., can solve the technical limitations of printed circuit boards, high prices and other problems, to improve scratch resistance, improve cross-linking Density, the effect of improving the yield of qualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better explain the present invention, the present invention will be further described below in conjunction with specific examples. The formulations of each example are shown in Table 1, wherein Example 1 and Example 2 are comparative reference examples, and the amounts of materials used in each example are weight percentages (%).

[0041] Table 1 specific embodiment

[0042]

[0043] Note*: Color paste is obtained by mixing, dispersing and grinding 15% pigment, 84.6wt.% main resin and 0.4wt.% dispersant.

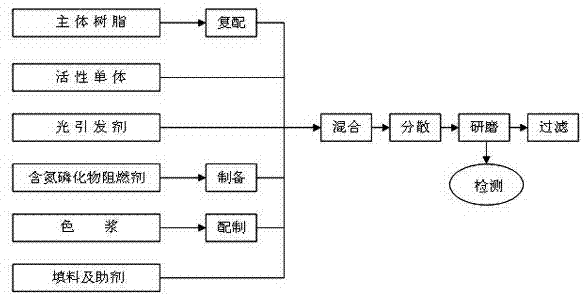

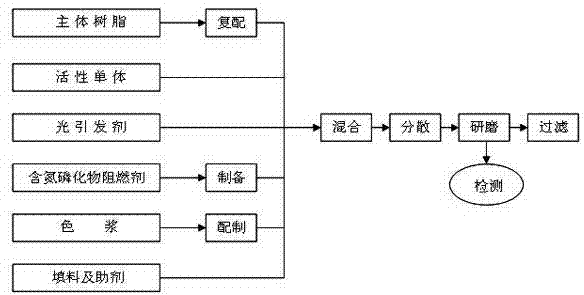

[0044] All the above examples were prepared according to the following steps: (1) Compounding of the main resin: put acrylate modified novolac epoxy resin and β-hydroxyethyl acrylate modified melamine formaldehyde resin into the resin compounding barrel, and use high-speed dispersion The mixing machine is stirred at a speed of 500~800r / min until it is mixed until uniform; (2) Preparation of color paste: 15% pigment by weight, 84.6% main resin and 0.4% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pencil hardness | aaaaa | aaaaa |

| Temperature resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com