C-axis device of CNC vertical lathe

A CNC vertical and shaft device technology, applied in metal processing and other directions, can solve the problems of low positioning accuracy, unable to achieve positioning accuracy drilling and milling functions, etc., and achieve processing efficiency and accuracy improvement, comprehensive processing efficiency and accuracy, and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

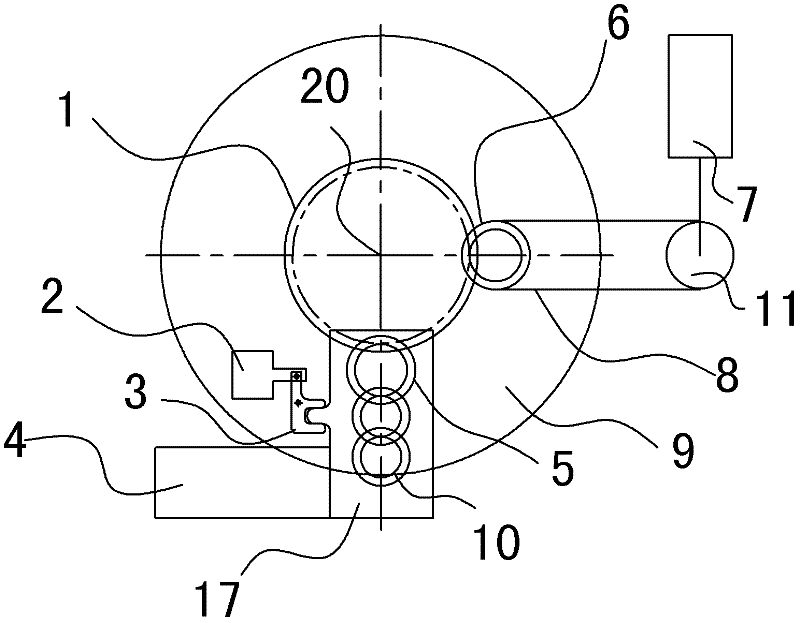

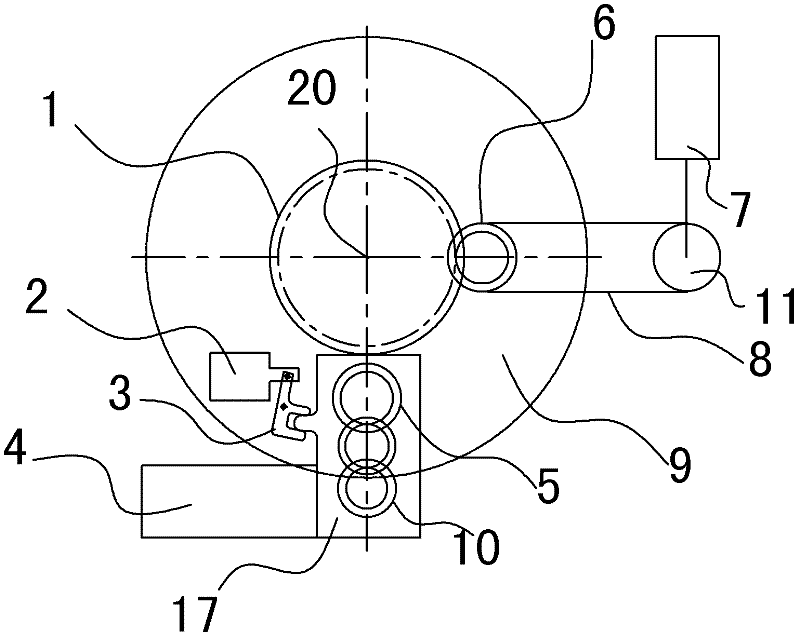

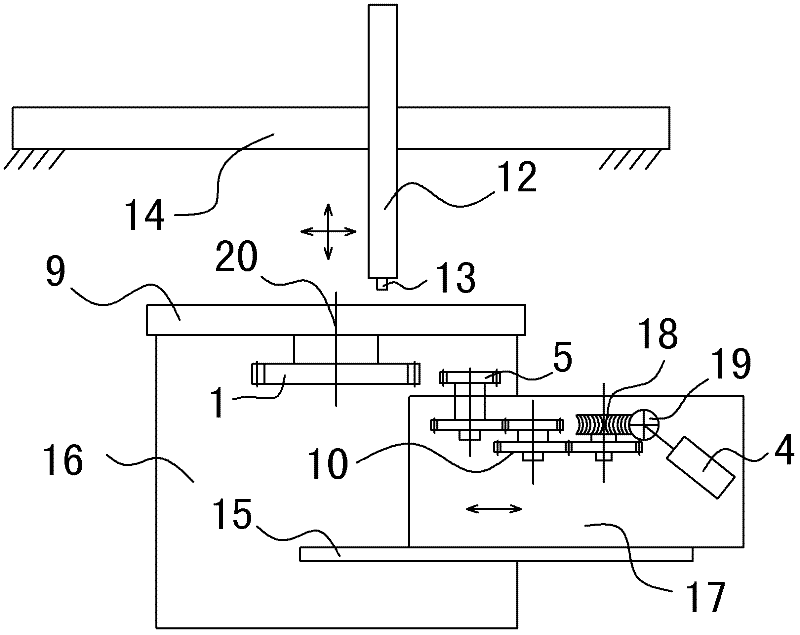

[0018] Embodiment: A C-axis device of a numerically controlled vertical lathe

[0019] Such as figure 1 , figure 2 with image 3 As shown, the C-axis device is arranged beside the first gear 1 that drives the table 9 to rotate and is fixedly connected with the main shaft 20 . The C-axis device is mainly composed of a servo motor 4, a transmission mechanism, a slide rail 15, a sliding seat 17 and a linear drive mechanism 2. Wherein, the transmission mechanism is composed of a pair of worm gear mechanism and a group of gear transmission mechanism 10, the output shaft of the servo motor 4 is connected with the transmission of one end of the worm 19, one end of the worm wheel 18 is connected with the input end of the gear transmission mechanism 10, and the gear transmission mechanism The output end of 10 is provided with a second gear 5, and the second gear 5 cooperates with the first gear 1. Both the servo motor 4 and the transmission mechanism are installed on the sliding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com