Method and device for solid fuel powder combustion and work

A solid fuel and powder technology, applied in the direction of combustion methods, burners for burning powder fuel, gas turbine devices, etc., can solve problems such as trouble, blockage, melting and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

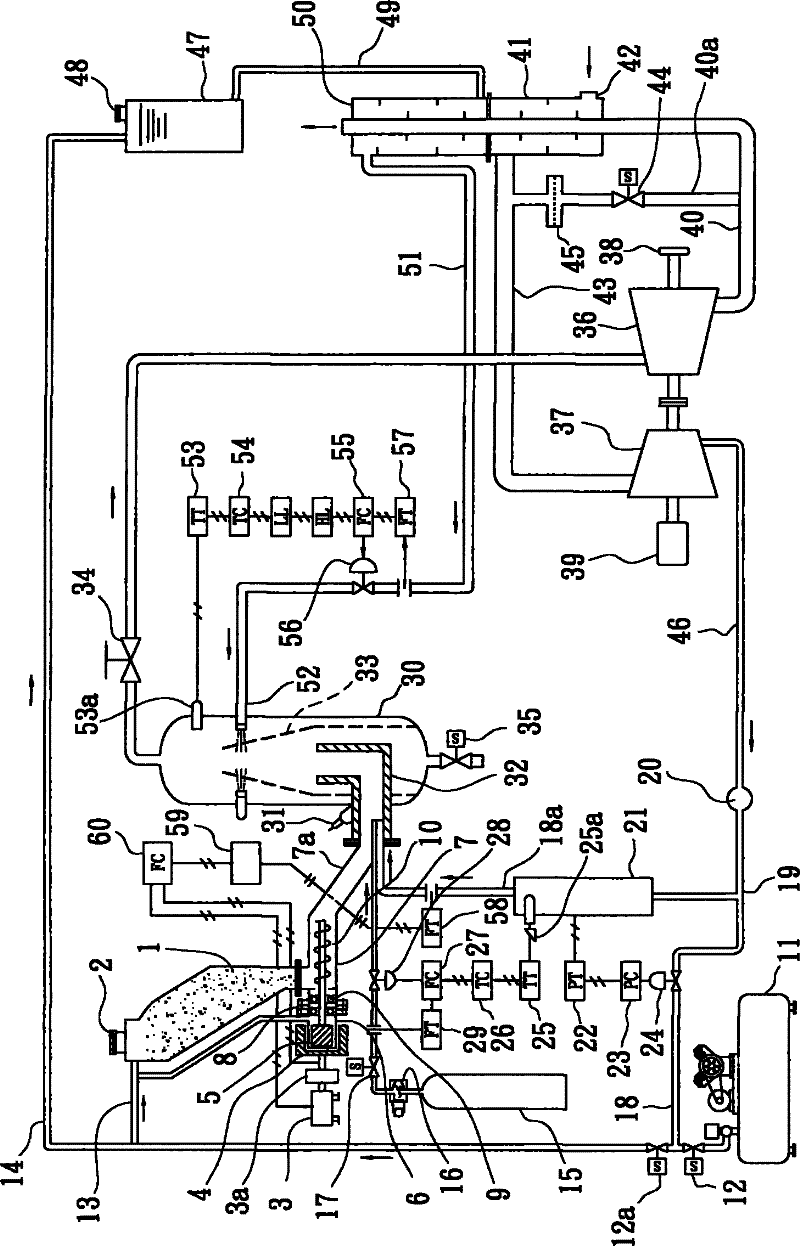

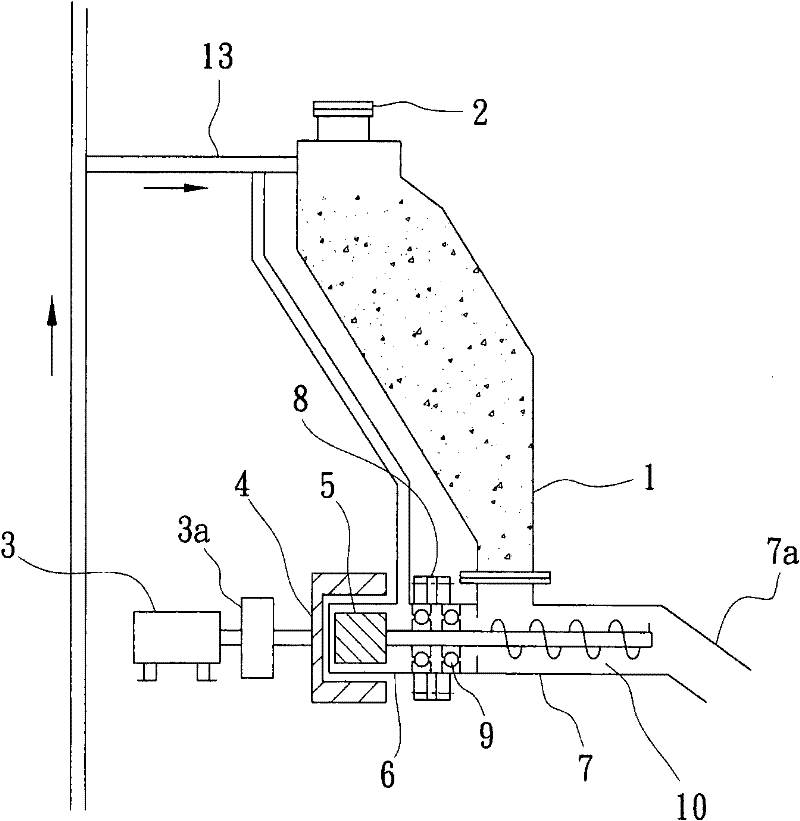

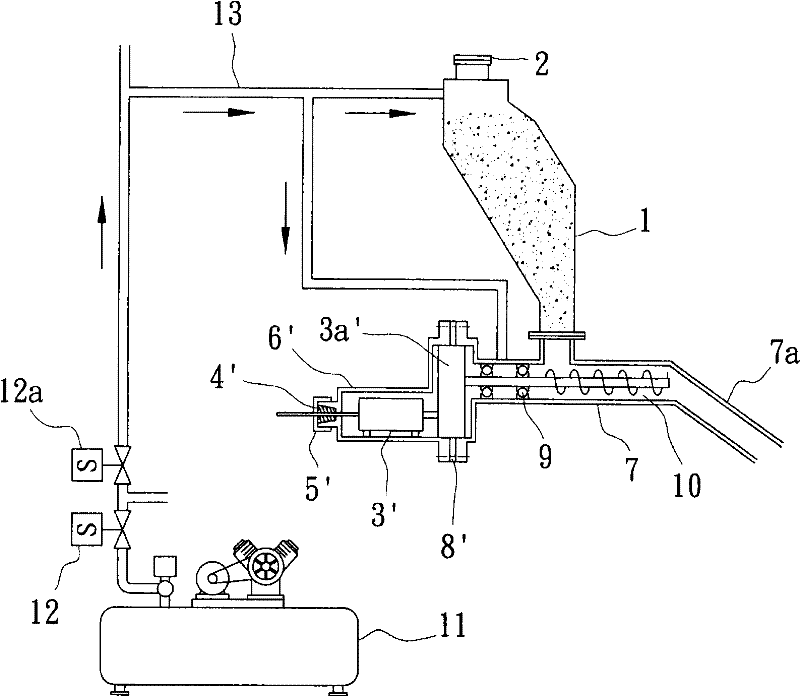

[0052] In order to make the features and advantages of the present invention more clearly understood, preferred embodiments of the present invention will be described in detail below together with the accompanying drawings. see figure 1 As shown, a solid fuel powder of the present invention utilizes a closed screw feeder to input the method and device for burning and working in an open-cycle gas turbine combustor, including a storage tank whose bottom communicates with a closed screw feeder 7 1. An airtight screw feeder 7, a burner 30, a gas turbine 36 and a compressor 37, wherein:

[0053] The storage tank 1 is a pressure-resistant tank with the function of accommodating solid fuel powder and allowing the solid fuel powder to fall into the closed screw feeder 7 from the bottom; the top is provided with a cover 2 that can be opened to load the fuel powder; the cover 2 It can also be closed tightly so that the high-pressure combustion gas is not allowed to leak out; the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com