A method for separating and recovering chloroperoxidase

A chloroperoxidase, separation and recovery technology, applied in the biological field, can solve the problems of complex composition of fermentation broth, low chromatographic purification products, large content of cell metabolites, etc., shorten the purification cycle, improve extraction interference, and volume requirements small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of CPO fermentation broth

[0024] Press the Caldariomyces fumago lawn cultivated on the PDA plate for 10 days by 2 cm 2 The inoculum of bacterial lawn / 250mL Erlenmeyer flask was inserted into the fermentation medium (including g / L: maltose 40, NaNO 3 2, KCl2, KH 2 PO 4 2. MgSO 4 ·7H 2 O 0.5, FeSO 4 ·7H 2 O 0.02, CaCl 2 0.09, plus 20% potato extract by volume, the initial pH is 7.0), the liquid volume in the shaker flask is 50ml / 250mL, the fermentation temperature is 25°C, the shaker speed is 240r / min, and the fermentation is 6d.

[0025] (2) Pretreatment of CPO fermentation broth

[0026] Centrifuge the fermented liquid at 4000g and 10°C for 10 minutes, or use vacuum filtration to remove mycelium and other solids, collect the supernatant containing melanin, and slowly add the supernatant to an amount equal to 6% of the supernatant in an ice bath. % PEG400 with constant stirring and mixing, let stand for 4 hours until the flocculation of PEG ...

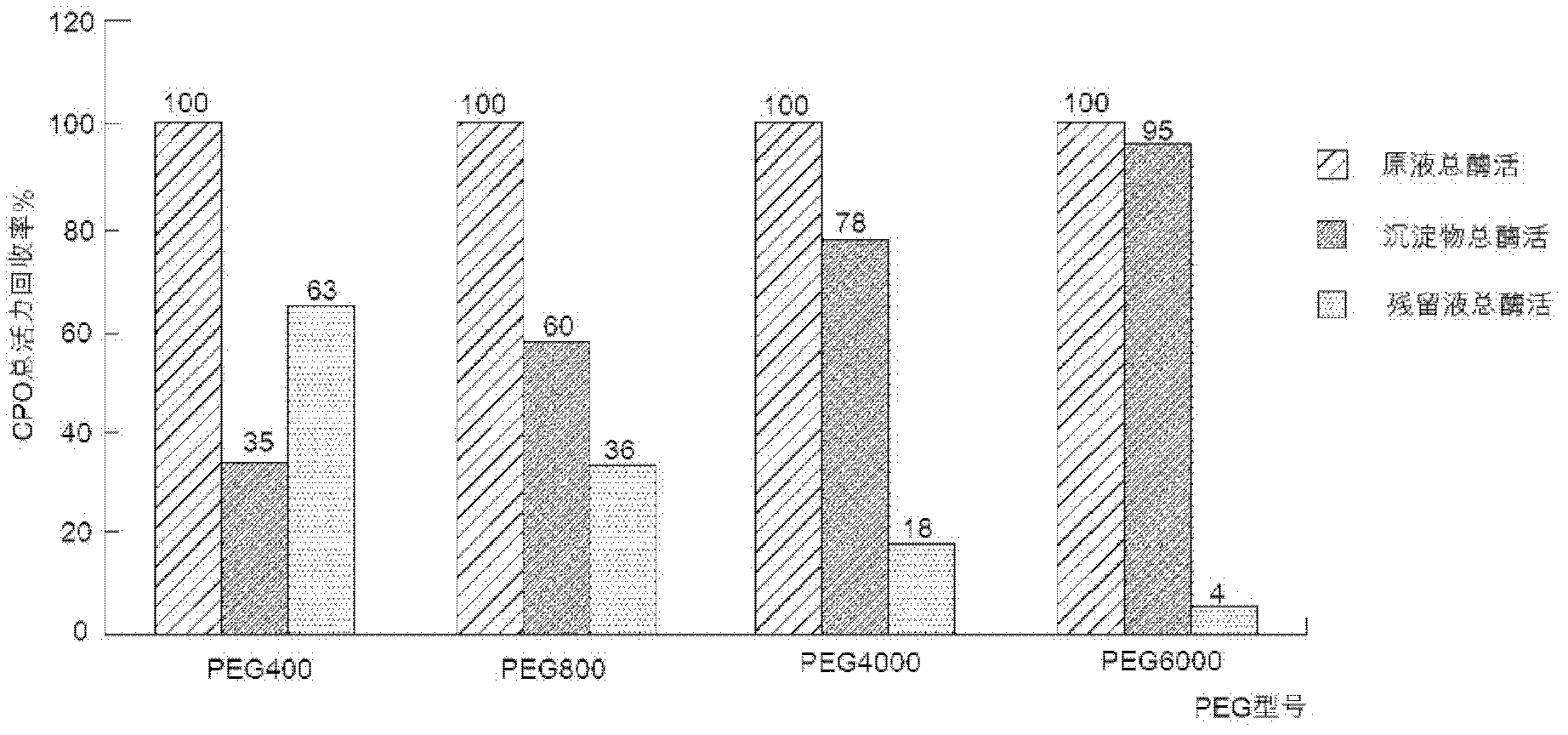

Embodiment 2

[0032] The process is the same as in Example 1, except that step (2) uses PEG800.

[0033] The results show that the total enzyme activity of the sediment is 60% of the total enzyme activity of the stock solution, the total enzyme activity of the residual solution is 36% of the total enzyme activity of the stock solution, and the total enzyme activity loss is 4%. It shows that the recovery effect of CPO using PEG800 is still unsatisfactory, but it is significantly improved compared with using PEG400.

Embodiment 3

[0035] The process is the same as in Example 1, except that step (2) uses PEG4000.

[0036] The results show that the total enzyme activity of the sediment is 78% of the total enzyme activity of the stock solution, the total enzyme activity of the residual solution is 18% of the total enzyme activity of the stock solution, and the total enzyme activity loss is 4%. It shows that the use of PEG4000 has a better recovery effect on CPO, but the loss of total enzyme activity is greater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com