Thermosetting weather-resistant low-temperature curing powder

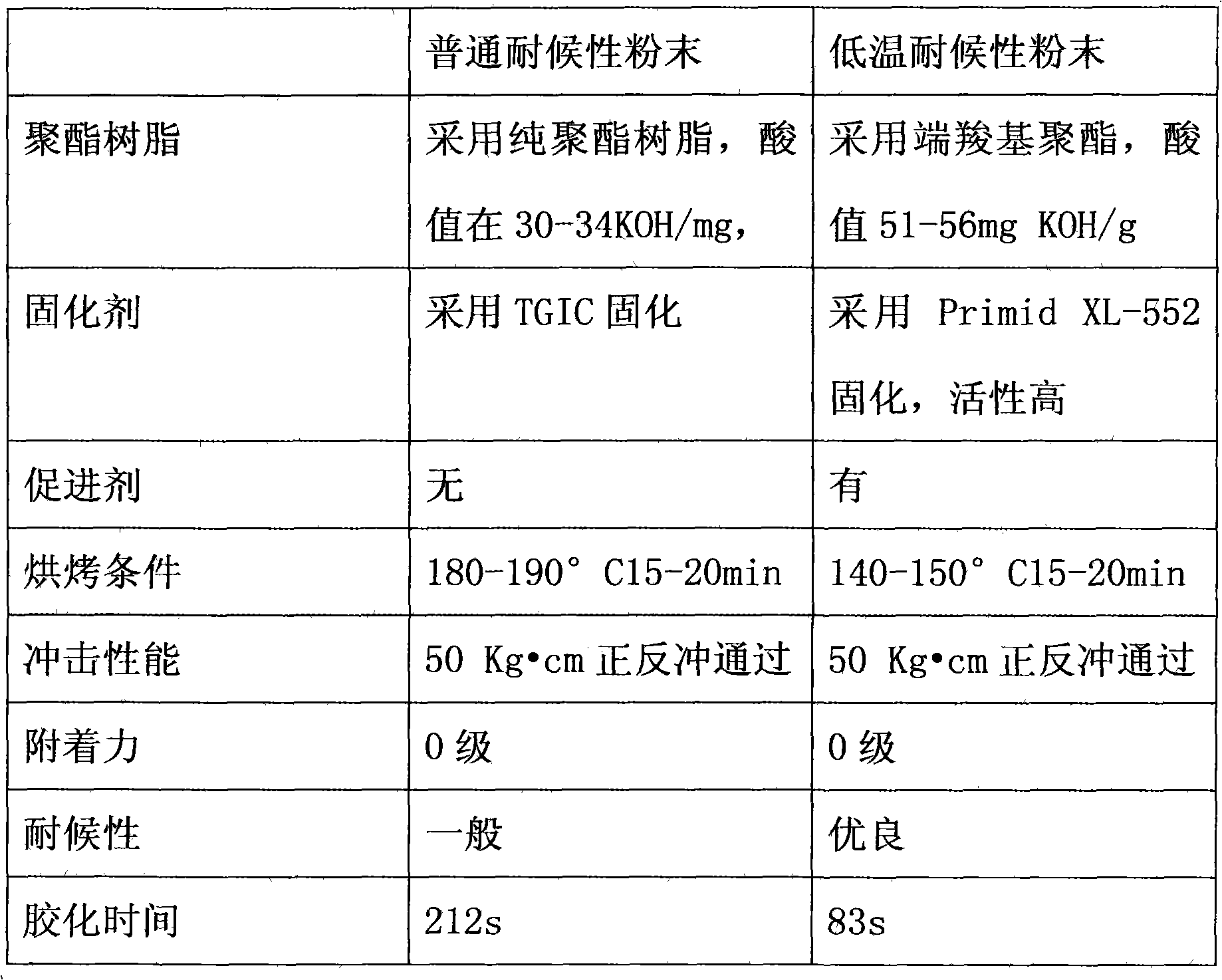

A weather-resistant, thermosetting technology, used in powder coatings, coatings, pre-treated surfaces, etc., to achieve the effect of shortened curing time, good weather resistance, and unaffected mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

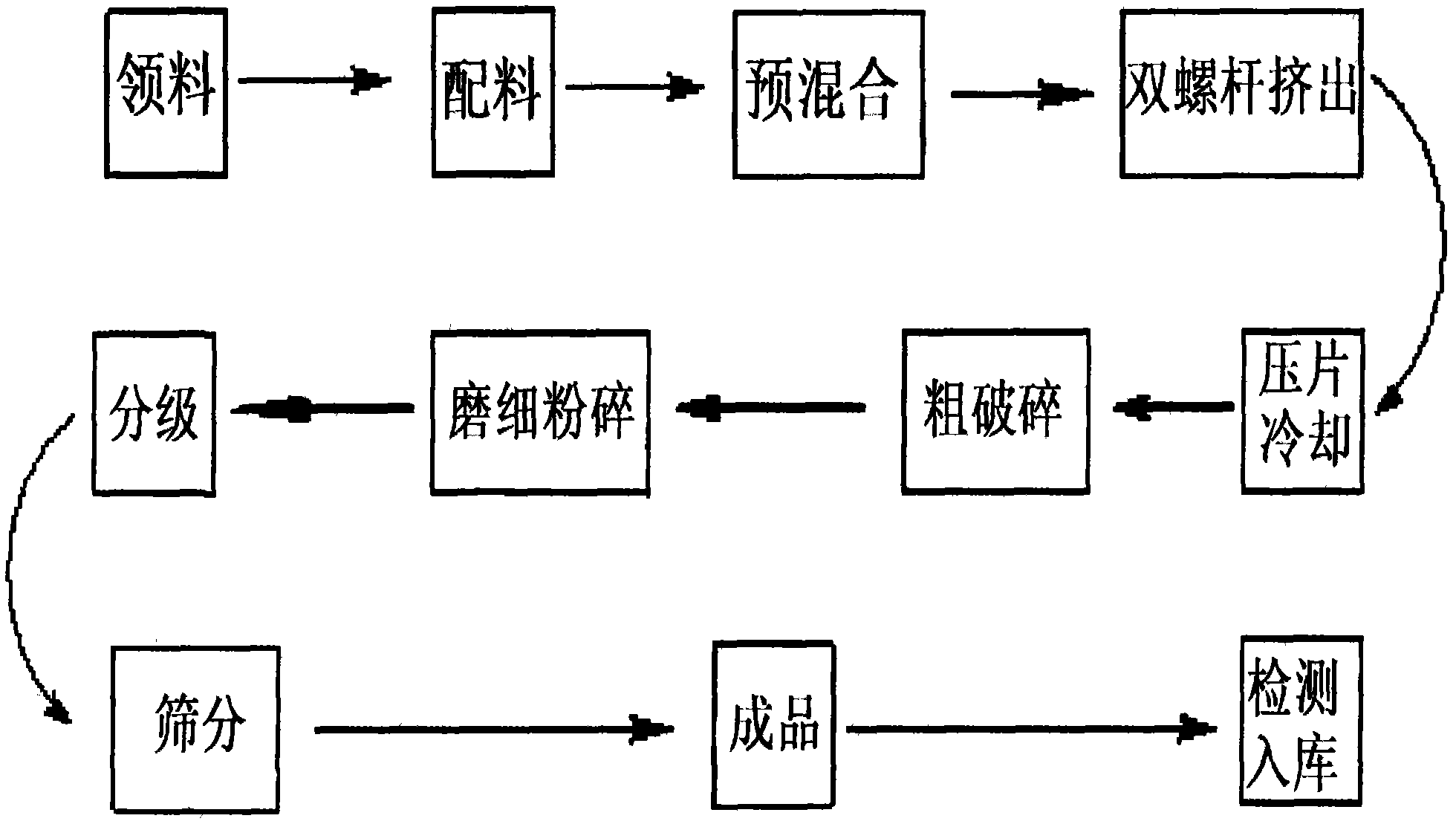

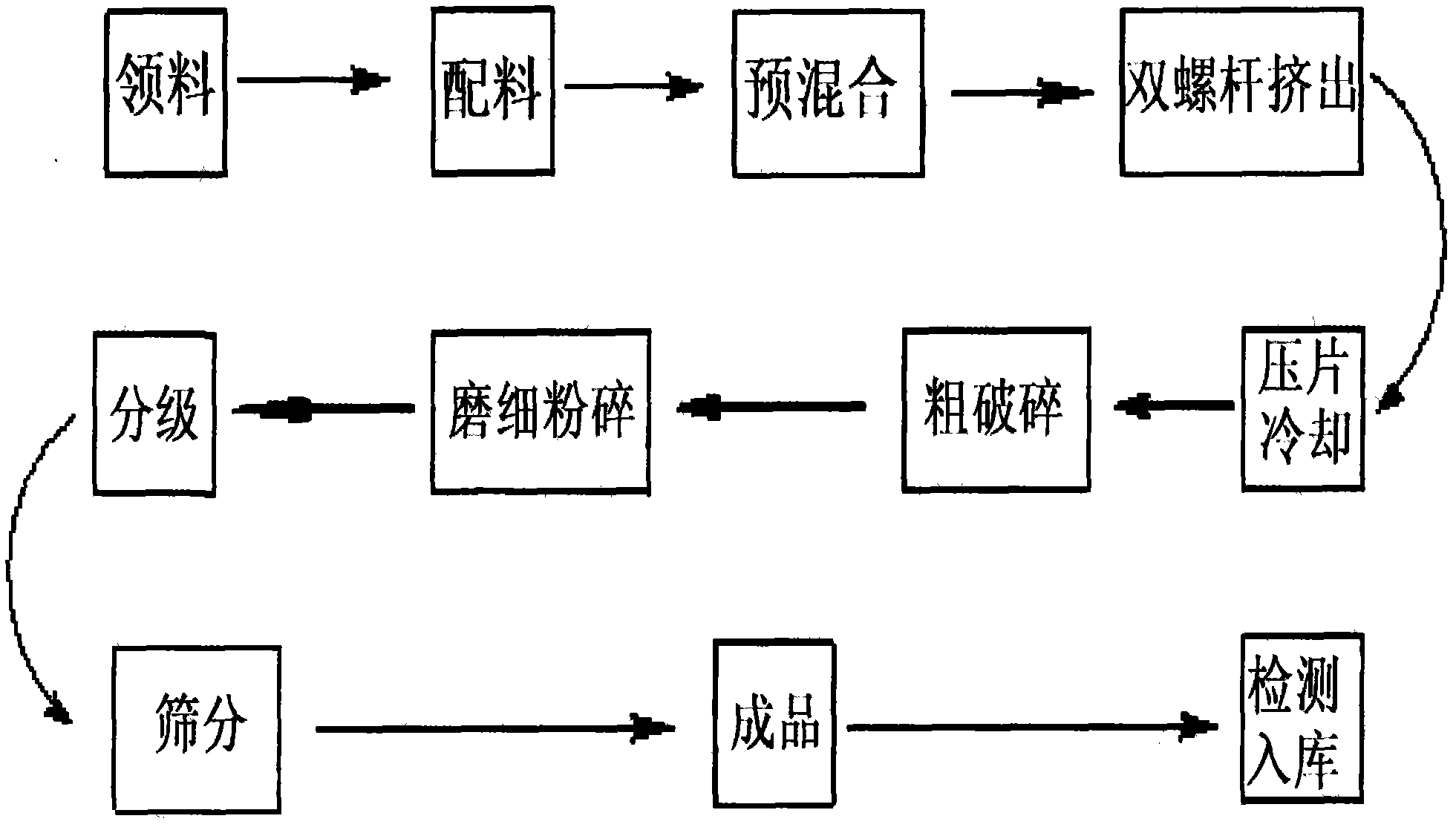

Method used

Image

Examples

Embodiment 1

[0041] According to the following ratio of raw materials:

[0042] raw material

[0043] According to the above processing method, the product can achieve the highest performance, the gloss is 91 degrees, the curing condition is 150 ℃, and it can be cured within 20 minutes.

Embodiment 2

[0045] According to the following ratio of raw materials:

[0046] raw material

[0047] According to the above processing method, the product can achieve the highest performance, the gloss is 54 degrees, and the curing condition is 150 ℃, within 20 minutes.

Embodiment 3

[0050] According to the above processing method, the product can achieve the highest performance, gloss 5 degrees, curing condition 150 ℃, within 20 minutes.

[0051] Example 1-3 of the present invention product quality detection index is as follows: coating film main performance (curing condition 150 ℃, 20 minutes, test substrate: 1mm galvanized steel plate)

[0052] Recipe 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com