A kind of preparation method of graphene and manganese dioxide nanocomposite material

A nanocomposite material and manganese dioxide technology are applied in the field of preparation of graphene and manganese dioxide nanocomposite materials, which can solve the problems of different morphology, agglomeration phenomenon, inability to exert special properties and advantages, etc., and achieve a simple and convenient preparation method. The effect of easy operation, enlarged reaction area and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

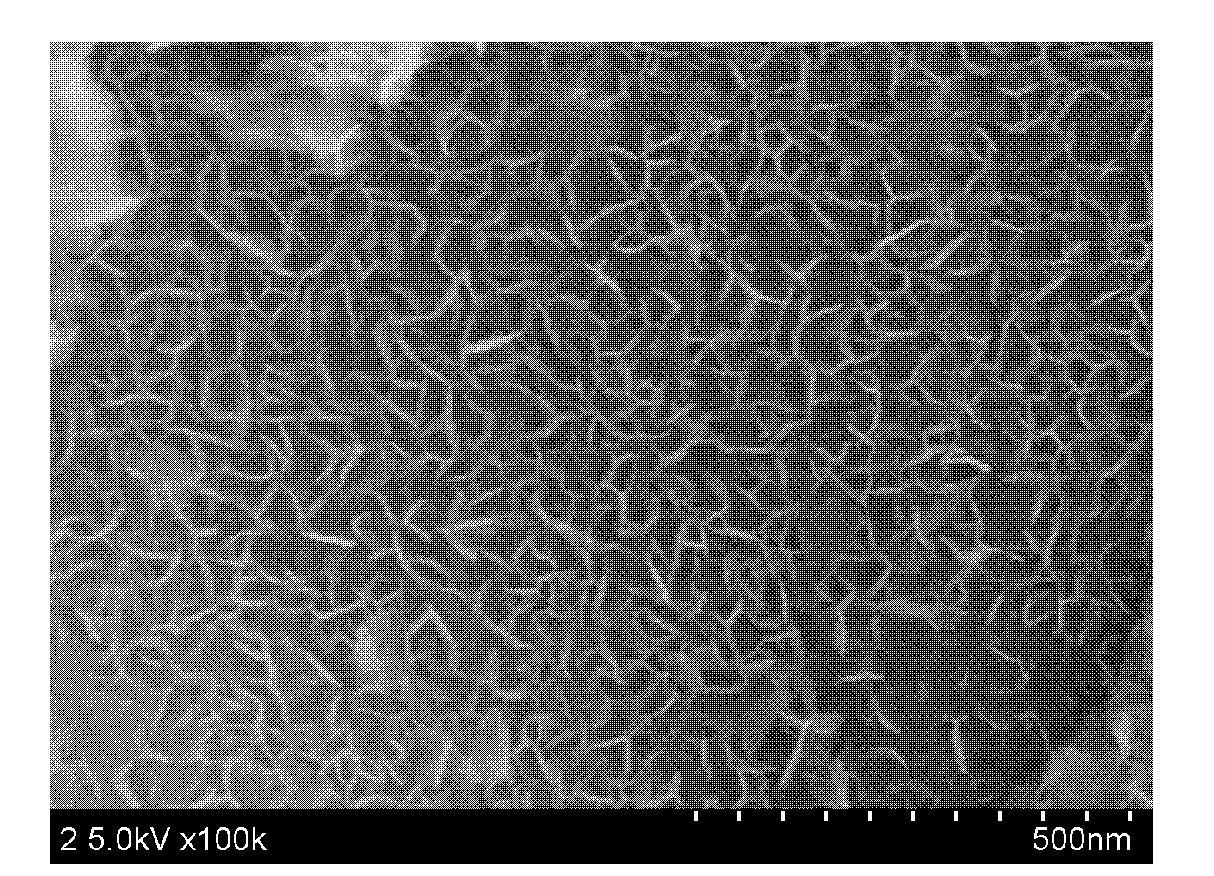

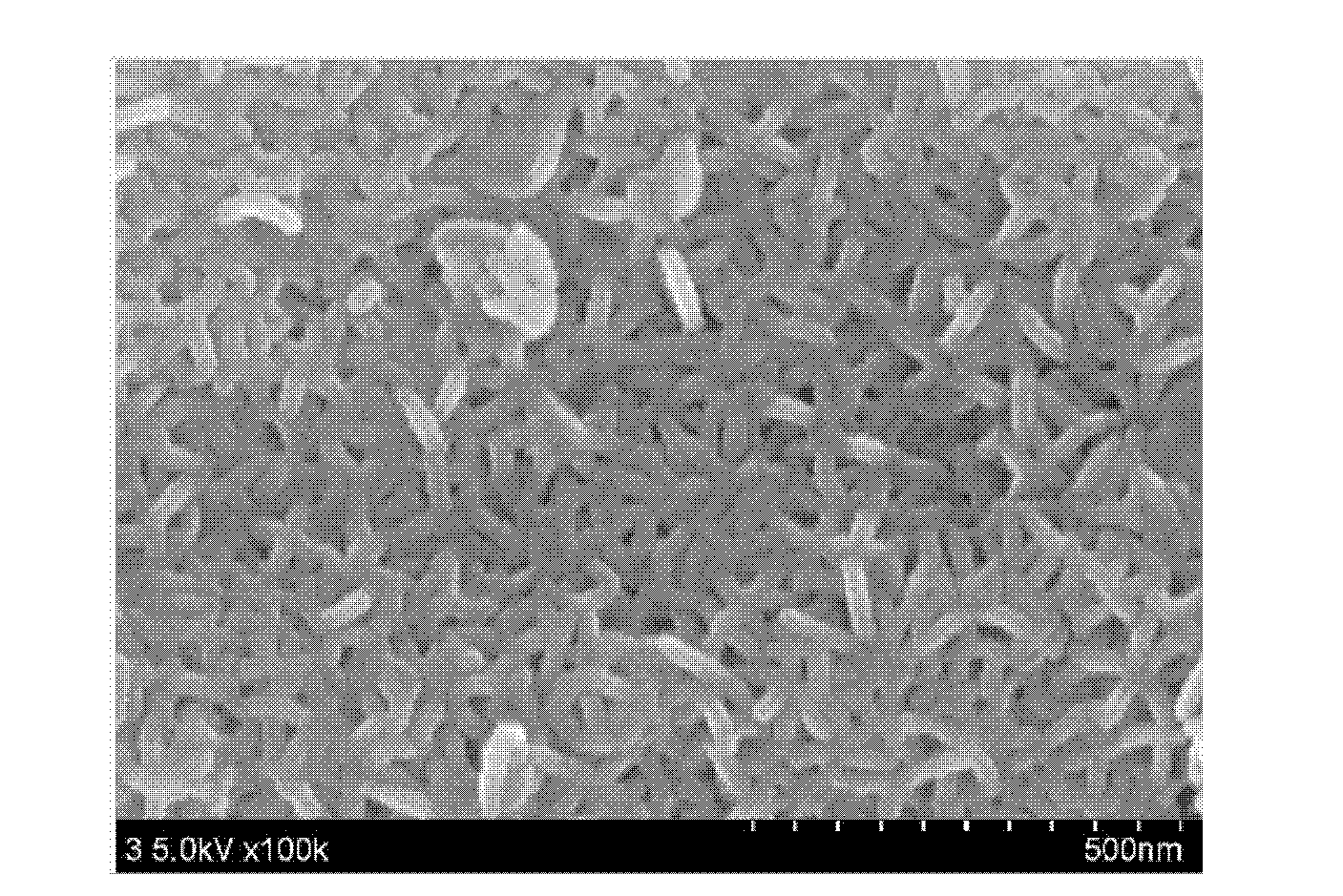

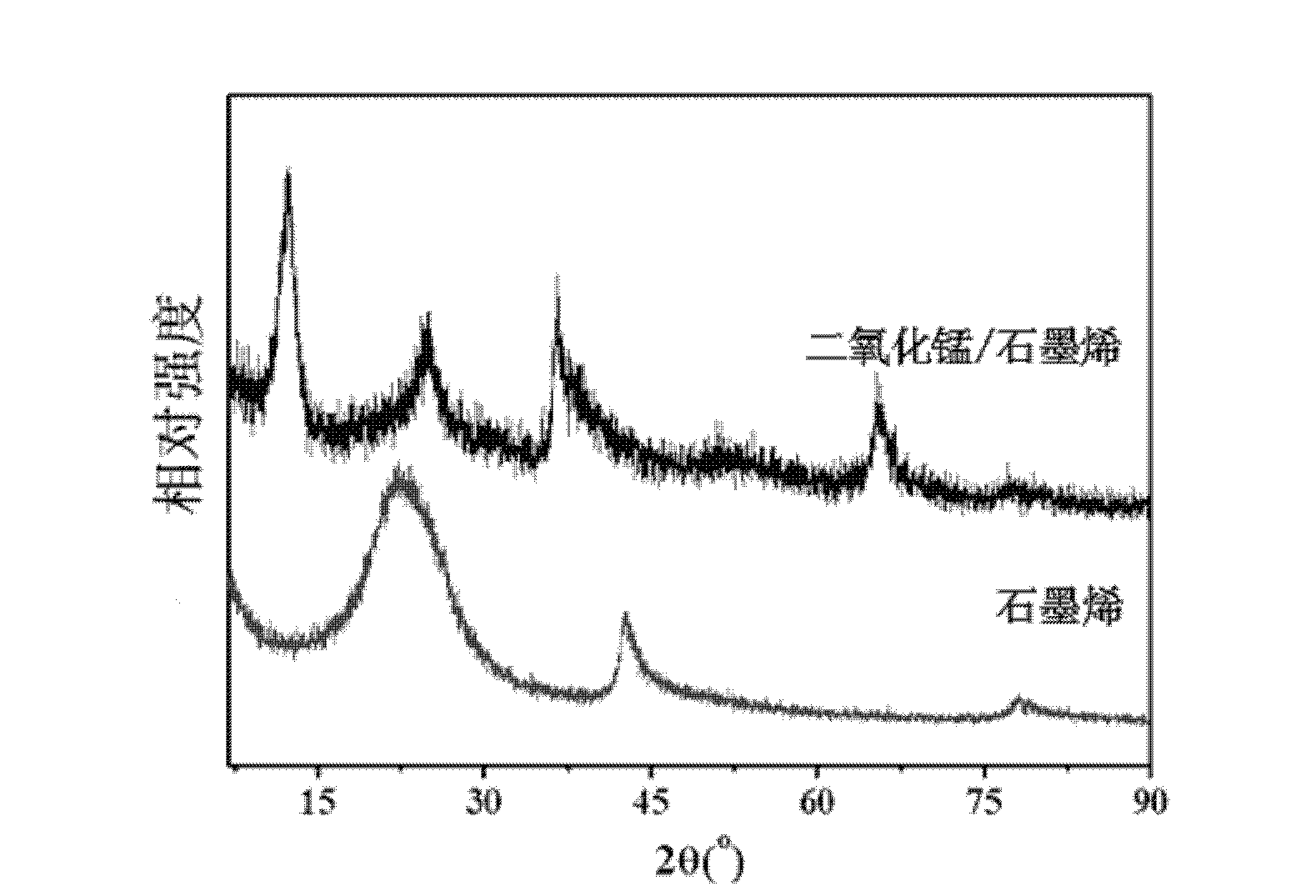

[0028] First mix 1g graphite, 0.75g sodium nitrate and 23ml 98wt.% sulfuric acid in an ice-water bath and mix well, gradually add 3g potassium permanganate within 0.5h; then react in a 35℃ water bath for 40min; then at room temperature Add 46ml of deionized water and stir for 15min, and finally add 140ml of deionized water and 10ml of hydrogen peroxide; the resultant product is repeatedly filtered and washed until it is neutral to obtain graphite oxide. Disperse 0.1 g of graphite oxide into 50 ml of water, add 0.1 ml of hydrazine hydrate, and reflux in a 95° C. water bath for 1 hour. The resulting product is repeatedly filtered and washed until it is neutral to obtain graphene. Then add 0.1g graphene to 50ml deionized water; after ultrasonic dispersion for 1h, add 2.724g potassium permanganate saturated solution, drop 3.1g hydrochloric acid, and ultrasonically assist the reaction at 70℃ for 3h; the resulting product is repeatedly filtered Washing until it is neutral, and vacuum...

Embodiment 2

[0030] First mix 1g graphite, 0.75g sodium nitrate and 23ml 98wt.% sulfuric acid in an ice water bath and mix well, gradually add 3g potassium permanganate within 0.5h; then react in a water bath at 35℃ for 20min; then at room temperature Add 46ml of deionized water and stir for 15min, and finally add 140ml of deionized water and 10ml of hydrogen peroxide; the resultant product is repeatedly filtered and washed until it is neutral to obtain graphite oxide. 0.1 g of graphite oxide was dispersed into 50 ml of water, 0.2 ml of hydrazine hydrate was added, and refluxed in a water bath at 95° C. for 1 h. The resulting product was repeatedly filtered and washed until it became neutral to obtain graphene. Then add 0.1g of graphene to 50ml of deionized water; after ultrasonic dispersion for 2h, add 1.816g of potassium permanganate saturated solution, add dropwise 2.06g of hydrochloric acid, and ultrasonically assist the reaction at 70°C for 2h; the resulting product is repeatedly filter...

Embodiment 3

[0032] First mix 1g graphite, 0.75g sodium nitrate and 23ml 98wt.% sulfuric acid in an ice-water bath and mix well, gradually add 3g potassium permanganate within 0.5h; then react in a 35℃ water bath for 40min; then at room temperature Add 46ml of deionized water and stir for 15min, and finally add 140ml of deionized water and 10ml of hydrogen peroxide; the resultant product is repeatedly filtered and washed until it is neutral to obtain graphite oxide. 0.1 g of graphite oxide was dispersed into 50 ml of water, 0.3 ml of hydrazine hydrate was added, and refluxed in a 95° C. water bath for 1 h. The resulting product was repeatedly filtered and washed until it became neutral to obtain graphene. Then add 0.1g graphene to 50ml deionized water; after ultrasonic dispersion for 3h, add 1.008g potassium permanganate saturated solution, drop 1g hydrochloric acid, and ultrasonically assist the reaction at 70℃ for 4h; the resulting product is repeatedly filtered and washed Until it is neu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com