A kind of method for preparing ferrous phosphate-based lithium salt material in high-pressure liquid phase

A ferrous phosphate-based, high-pressure liquid-phase technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problem of affecting the electrochemical performance of materials and electrodes, battery electrochemical performance, difficult to control crystallization uniformity, and complex preparation processes, etc. problem, to achieve the effect of improving electron mobility, reducing radius, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

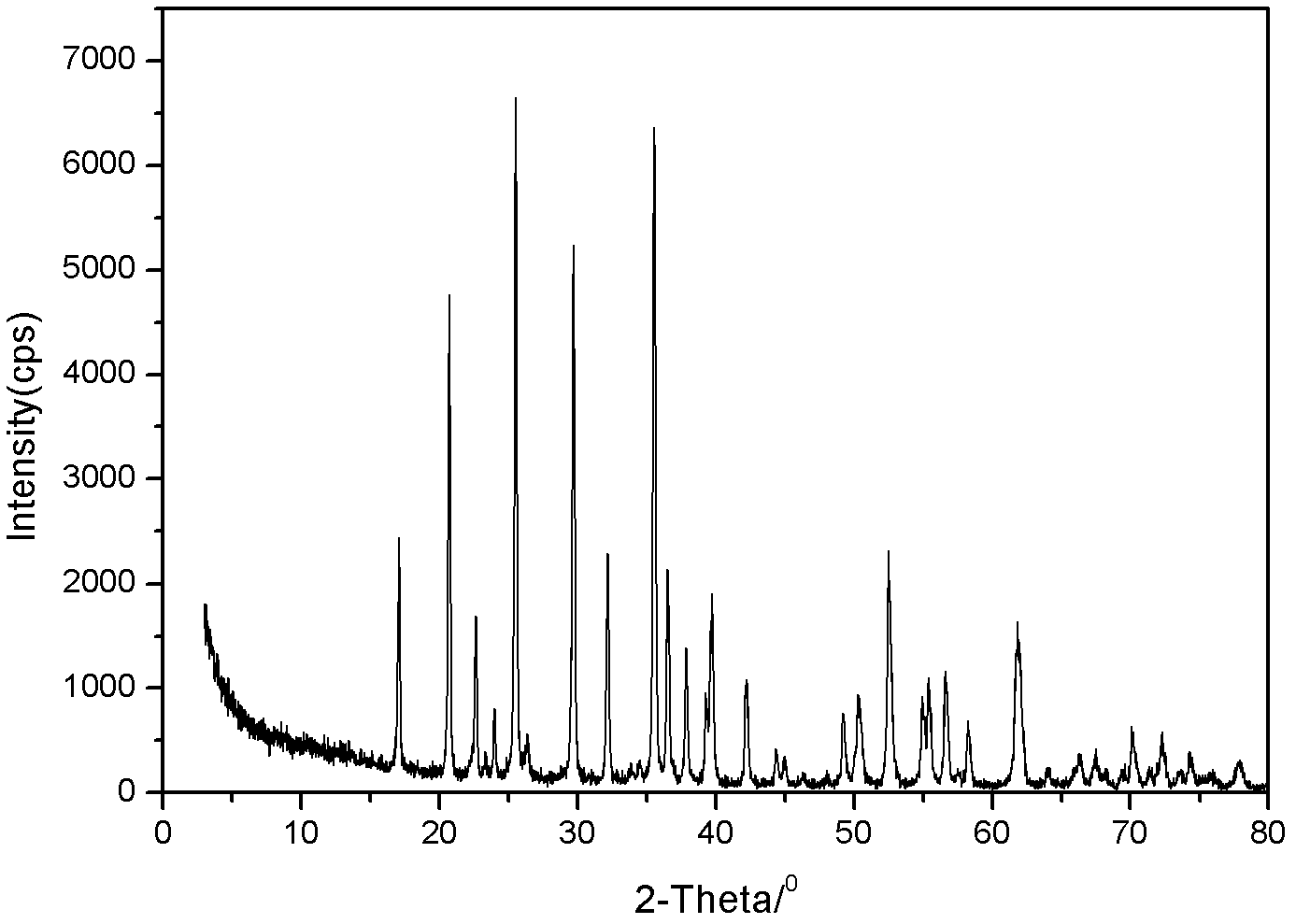

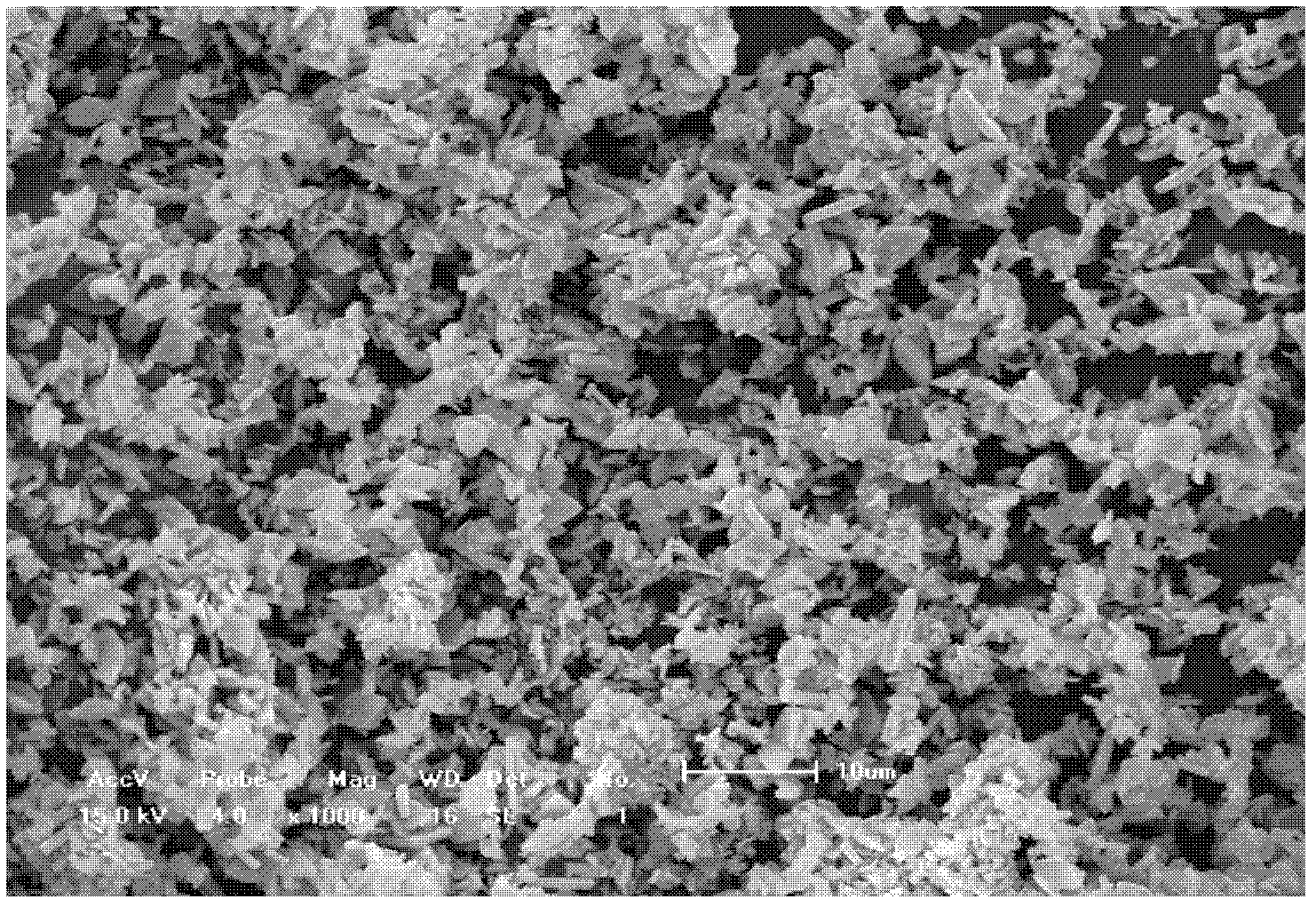

[0049] The lithium iron phosphate material is prepared by a high-pressure liquid phase method, and the preparation process is as follows:

[0050] 1) Under the reducing atmosphere of hydrogen, the mass percentage is 99.5% FeSO 4 ·7H 2 Adding 0.5% ascorbic acid in O to prepare iron salt solution, FeSO 4 ·7H 2 O solution and H 3 PO 4 According to the molar ratio of 1:1, the mixture is mixed in the liquid phase by stirring;

[0051] 2) LiOH·H 2 O and H in the above step 1) 3 PO 4 According to the molar ratio of 3:1, add it into the mixed solution and stir evenly, then add deionized water, and mix it into a white emulsion with a concentration of 3M;

[0052] 3) Transfer the homogeneously stirred emulsion in step 2) to a stainless steel hydrothermal reactor with polytetrafluoroethylene PTFE lining (the emulsion accounts for 50% of the volume of the reactor), and add the iron salt FeSO added in step 1). 4 ·7H 2 O mass percentage is 10% conductive agent carbon black, pass i...

Embodiment 2

[0057] The lithium iron phosphate material is prepared by a high-pressure liquid phase method, and the preparation process is as follows:

[0058] 1) LiOH·H 2 O solution and NH 4 h 2 PO 4 According to the molar ratio of 3:1, it is mixed in the liquid phase by stirring to form a mixed solution;

[0059] 2) Under a nitrogen reducing atmosphere, the mass percentage of 80% FeSO 4 ·7H 2 O solution was prepared by adding 20% tartaric acid, and the dissolved FeSO 4 ·7H 2 O with step 1) NH 4 h 2 PO 4 According to the molar ratio of 1:1, add it into the uniformly mixed solution and stir evenly, then add deionized water, and mix to form a white emulsion with a concentration of 1M;

[0060] 3) Transfer the homogeneously stirred emulsion in step 2) to a stainless steel hydrothermal reactor with polytetrafluoroethylene PTFE lining (the emulsion accounts for 80% of the volume of the reactor), and add the iron salt FeSO added in step 2). 4 ·7H 2 O mass percentage is 1% conducti...

Embodiment 3

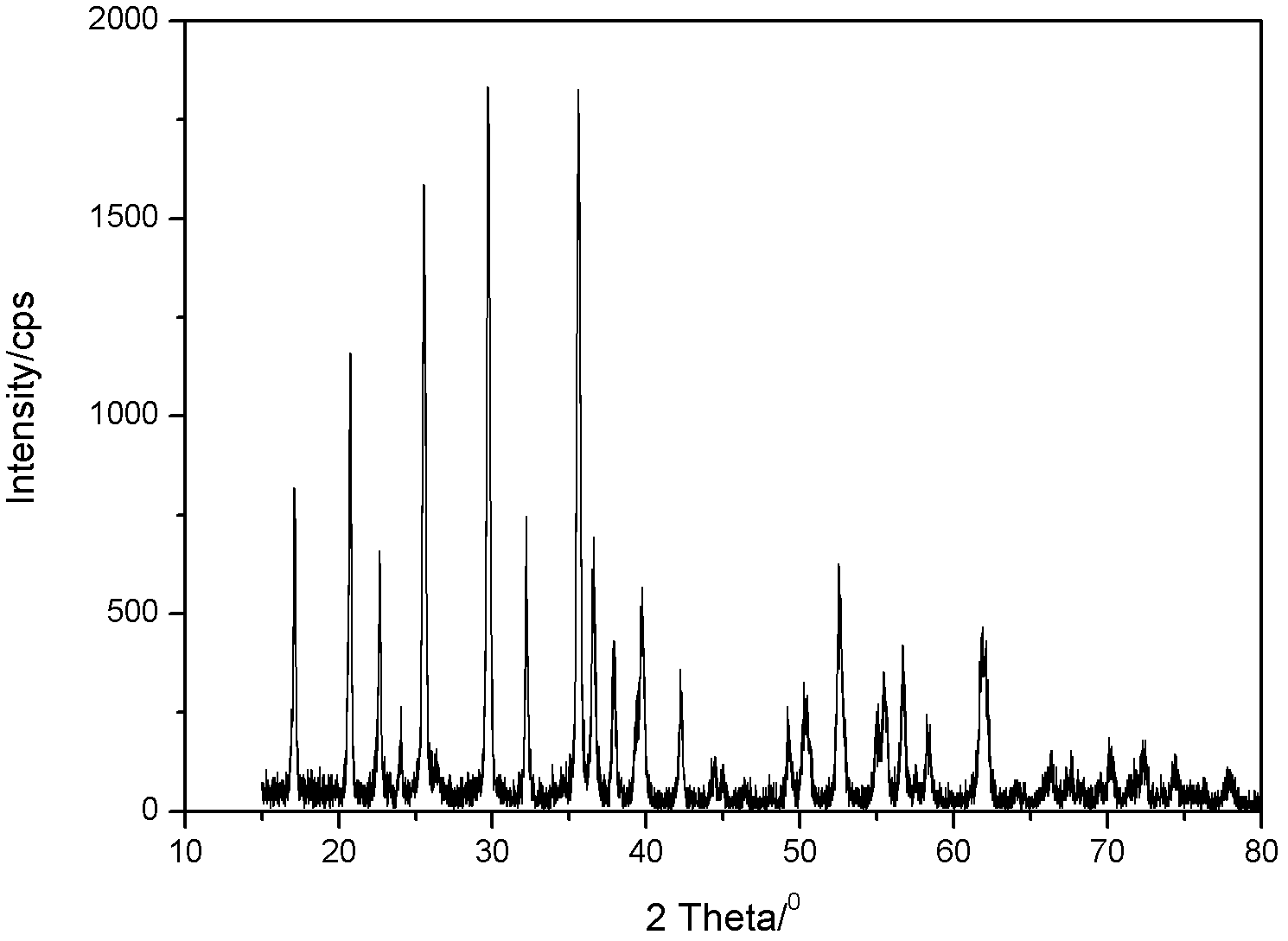

[0065] Preparation of doped lithium iron phosphate LiFe by high-pressure liquid phase method 1-x m x PO 4 , and its preparation process is as follows:

[0066] 1) Under a reducing atmosphere where nitrogen and hydrogen are mixed at a volume ratio of 9.5:0.5, according to FeSO 4 ·7H 2 O and MgSO 4 ·7H 2 O molar ratio is that the ratio of 99.9:0.1 is mixed with doped iron salt, is that 0.1% ascorbic acid is mixed with the ascorbic acid that adds mass percentage in 99.9% doping iron salt in mass percentage and is mixed with solution, FeSO 4 ·7H 2 O and MgSO 4 ·7H 2 O solution and H 3 PO 4 According to the molar ratio of 1:1, it is mixed into a solution in the liquid phase by stirring;

[0067] 2) LiOH·H 2 O follow with H 3 PO 4 Add the molar ratio of 3:1 to step 1) in the uniformly mixed solution and stir evenly, then add deionized water, and mix to form a 0.5M white emulsion;

[0068] 3) Transfer the homogeneously stirred emulsion in step 2) to a stainless steel h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com