Ceramic gas discharge metal halide lamps

A metal halide, gas discharge technology, applied in the field of argon-mercury mixture, ceramic gas discharge metal halide (CDM) lamps, can solve the problem of low lumen maintenance rate, and achieve the effect of reliable ignition characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

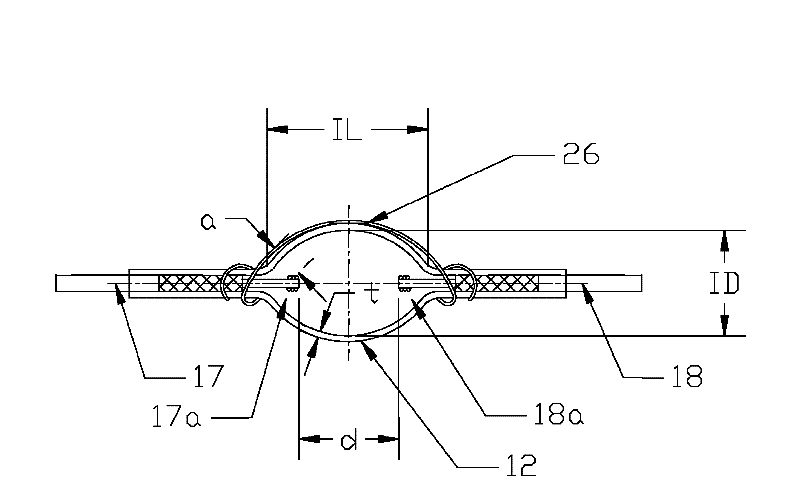

[0033] In order to demonstrate some of the advantages of the present invention, two sets of medium power (400W) CDM lamps (with and without antenna) were fabricated for testing with argon starting gas and traces of radioactive krypton, respectively, according to the prior art 85 and a neon-argon Penning mixture of 99.5 mole percent neon and 0.5 mole percent argon according to the present invention. These lamps employ an elliptical discharge vessel with an outer diameter of 18.4 mm, an overall length of 68 mm and a wall thickness of 1 mm. The starting gas filling pressure is 100mbar. The mean mercury dose was ~37 mg. The metal halide salt mixture included sodium, calcium, manganese, thallium, and rare earth iodides (40 mg dose level). The total amount of rare earth iodide is 3 mole percent. An oxygen dispensing agent is added to the lamp as disclosed in US Patent No. 6,362,571, the entire specification of which is hereby incorporated by reference.

[0034] The electrode dim...

example 2

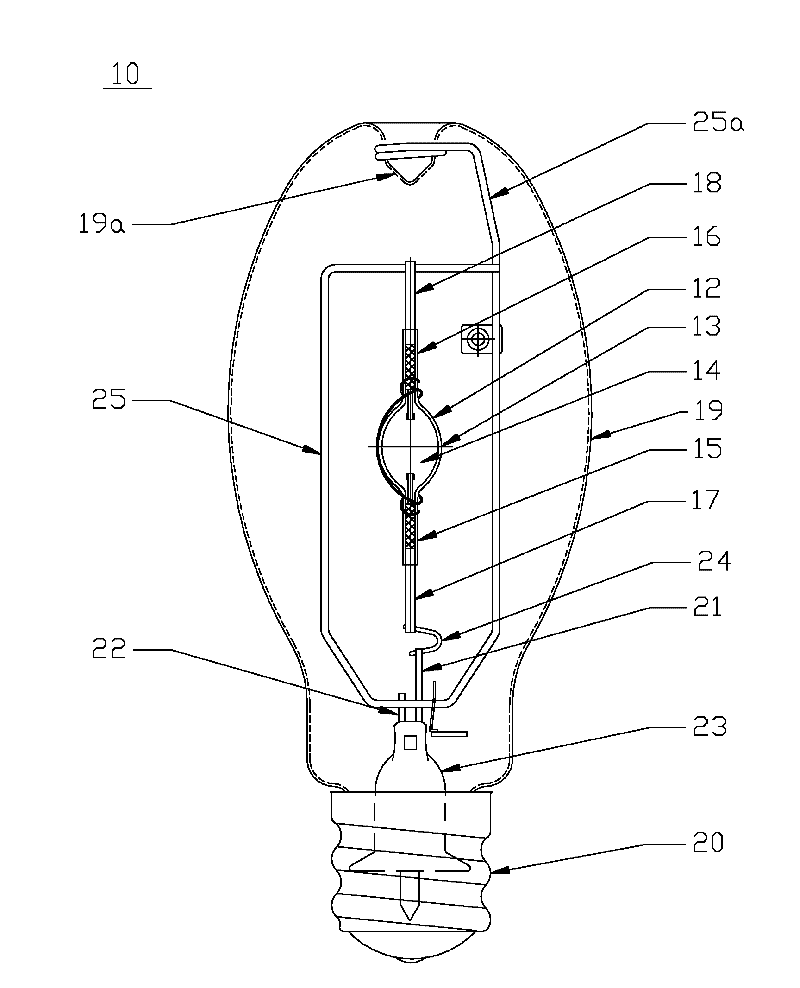

[0039] two groups figure 1 A 400W CDM lamp of the type shown in was prepared as described in Example 1, except that the starting gas filling for both sets of lamps was Ne:Ar (95%:0.5%); the filling gas pressure was 100 mbar; and the discharge vessel The aspect ratio is outside of 1.4.

[0040] In addition, a set of lights is provided with a starting aid in the form of a floating antenna made of Mo. Distance between antenna and discharge electrode a is 5mm.

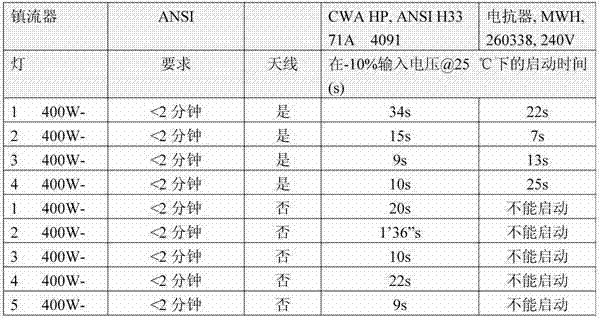

[0041] Startup was evaluated using two types of ballasts designed for high pressure mercury vapor lamps. The first ballast is a CWA ballast manufactured by Advanced Transformer Co. in accordance with American National Standard ANSI code H33 (OCV of 300v), the ballast product number is 71A 4091, and the second ballast is a reactance manufactured by MWH Ballast, the ballast part number is 260338.

[0042] Lamps without antennas start at nominal power, but not at -10% of nominal power. Lamps with antennas were started a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com