Biodegradable polylactic acid-starch heat-resistant composite material and preparation method thereof

A composite material, polylactic acid technology, applied in the field of polylactic acid-starch composite material and its preparation, to achieve the effect of good molding and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 20 parts of cornstarch, 1 part of polyvinyl alcohol, 1 part of maltitol and 1 part of water into a high-speed mixer with strong circulation according to the proportion, stir at 55 °C for 20 minutes, mix well, and cool down. material.

[0028] Add the mixture obtained above, 70 parts of polylactic acid, 1 part of ADK Stab Na-21, 2 parts of Biomax Thermal 300, 3 parts of SMA, and 1 part of super BPO into a high-speed mixer, mix evenly at 50 ° C, and dry , to get the mixture,

[0029] Then the above mixture is added to the twin-screw extruder, the ratio of length to diameter is 35:1, the screw speed is 200-300 rpm, and the temperature of each section is 150°C, 165°C, 170°C, 180°C, 170°C , 160°C, the vacuum degree of each section is extruded and granulated under the condition of 0.03 MPa, the mixture obtained above,

[0030] The pellets were then irradiated with 70KGy using gamma rays.

[0031] The tensile strength of the obtained composite material is 30MPa, the elo...

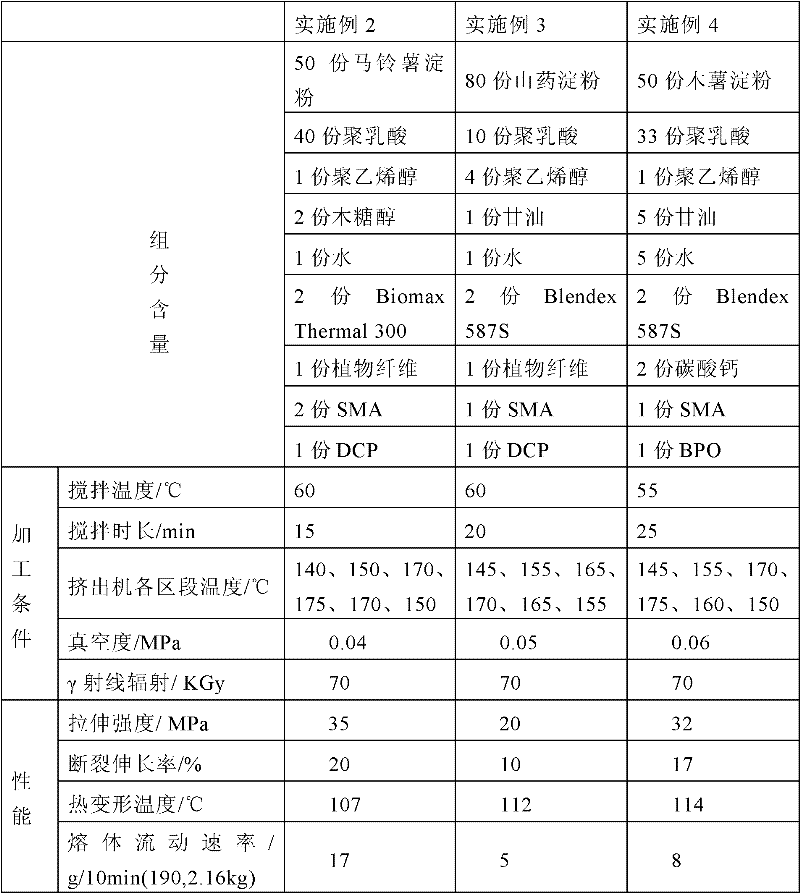

Embodiment 2~4

[0034]

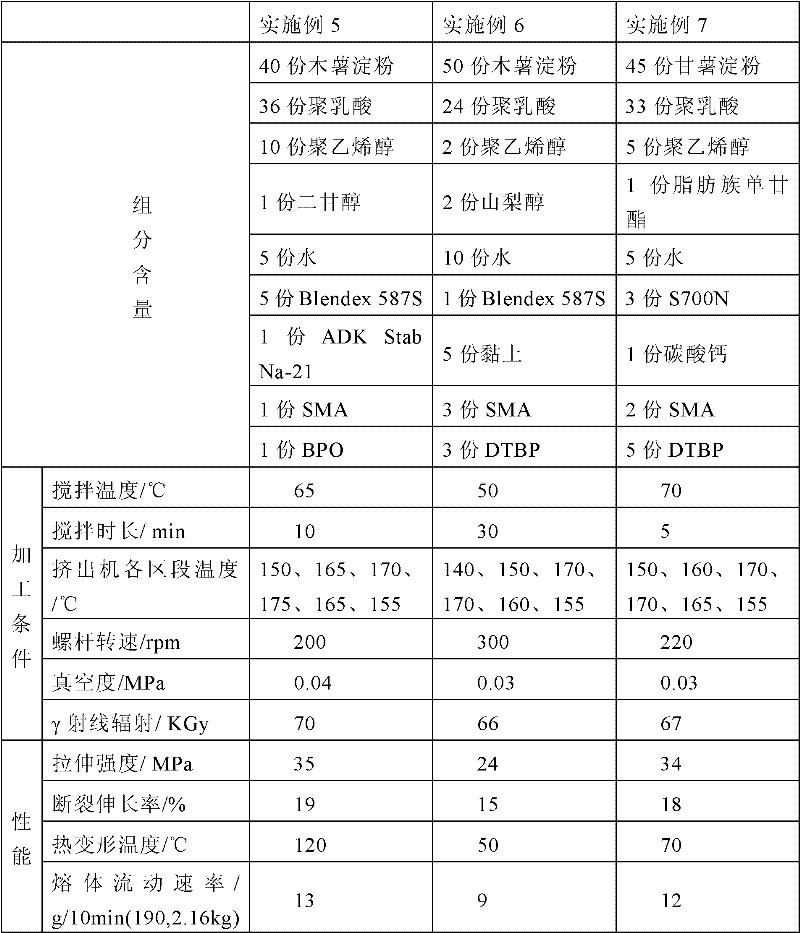

Embodiment 5~7

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com