Energy-saving and environment-friendly drying method and device for coal slime and lignite

An energy-saving and environmental-friendly lignite technology, applied in mineral drying and coal fields, can solve the problems of large energy waste, high production cost, return to the dryer, etc., and achieve the effects of reducing dust and CO2 emissions, reducing air heat pollution, and reducing the temperature of hot air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

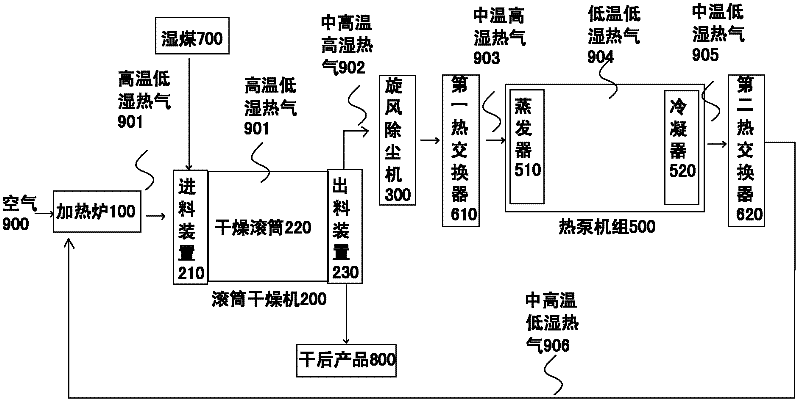

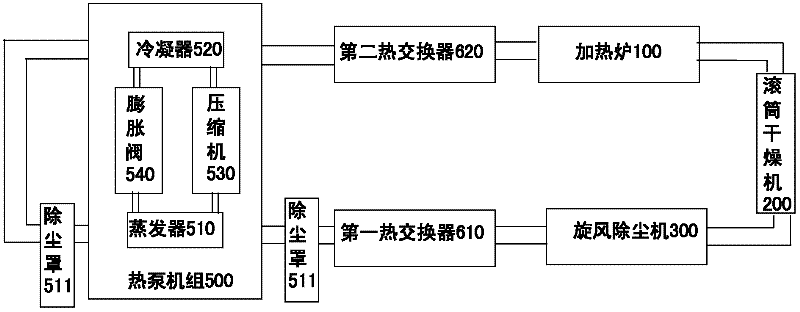

[0072] An energy-saving and environment-friendly drying device for coal slime and lignite, such as figure 2 and image 3 As shown, it includes: a heating furnace 100, a drum dryer 200, a cyclone dust collector 300, a first heat exchanger 610, a heat pump unit 500 and a second heat exchanger 620;

[0073] The heating furnace 100 is sequentially connected with the drum dryer 200 , the cyclone dust collector 300 , the first heat exchanger 610 , the heat pump unit 500 and the second heat exchanger 620 ; the second heat exchanger 620 is connected with the heating furnace 100 .

[0074] The prior art is only limited to hot blast stoves 110 using oil or coal. The heating furnace 100 of the present invention is a hot air furnace 110 that burns coal, gas, or oil, or an electric furnace.

[0075] The drum dryer 200 includes: a feeding device 210 , a drying drum 220 , and a discharging device 230 . The feeding device 210 is at the entrance of the front end, the drying drum 220 is in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com