New Blast Furnace Gas Dispersion and Automatic Ignition System

A blast furnace gas, automatic ignition technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as unenvironmental protection and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

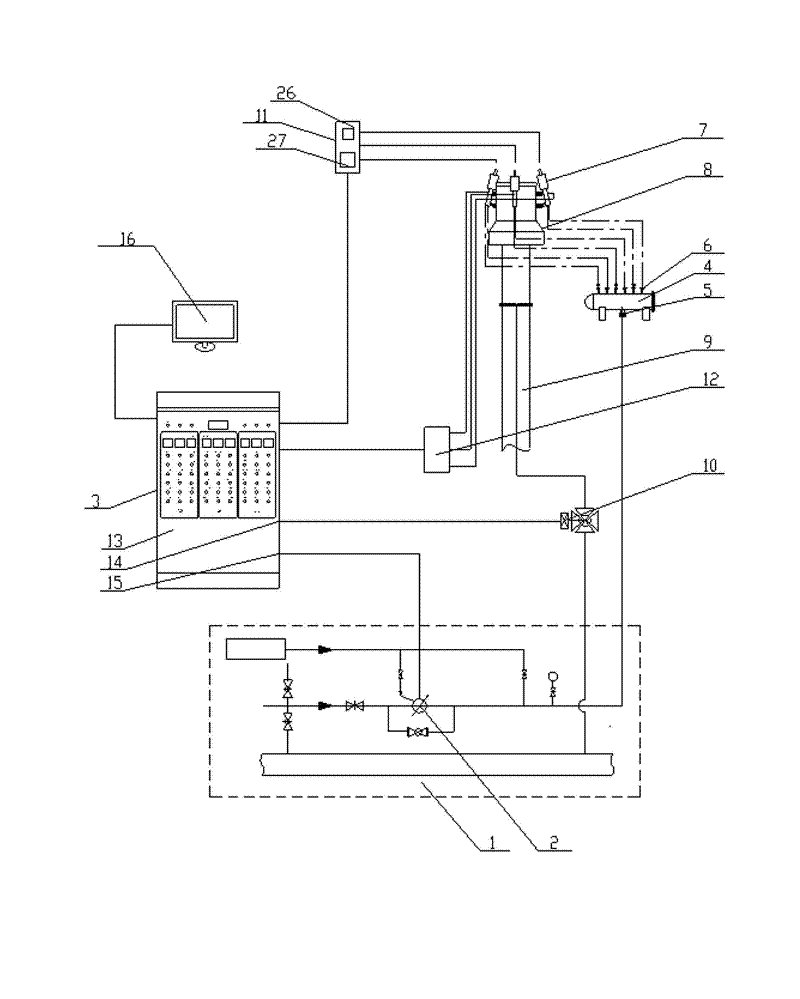

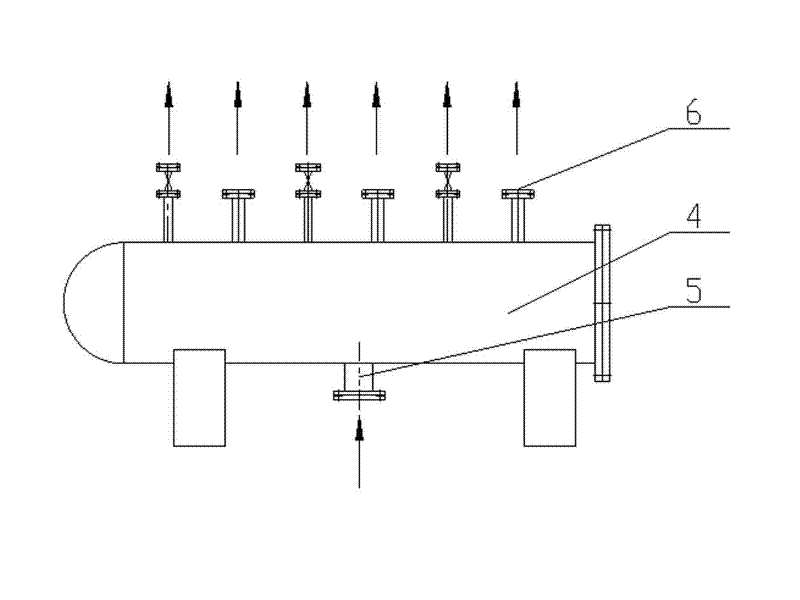

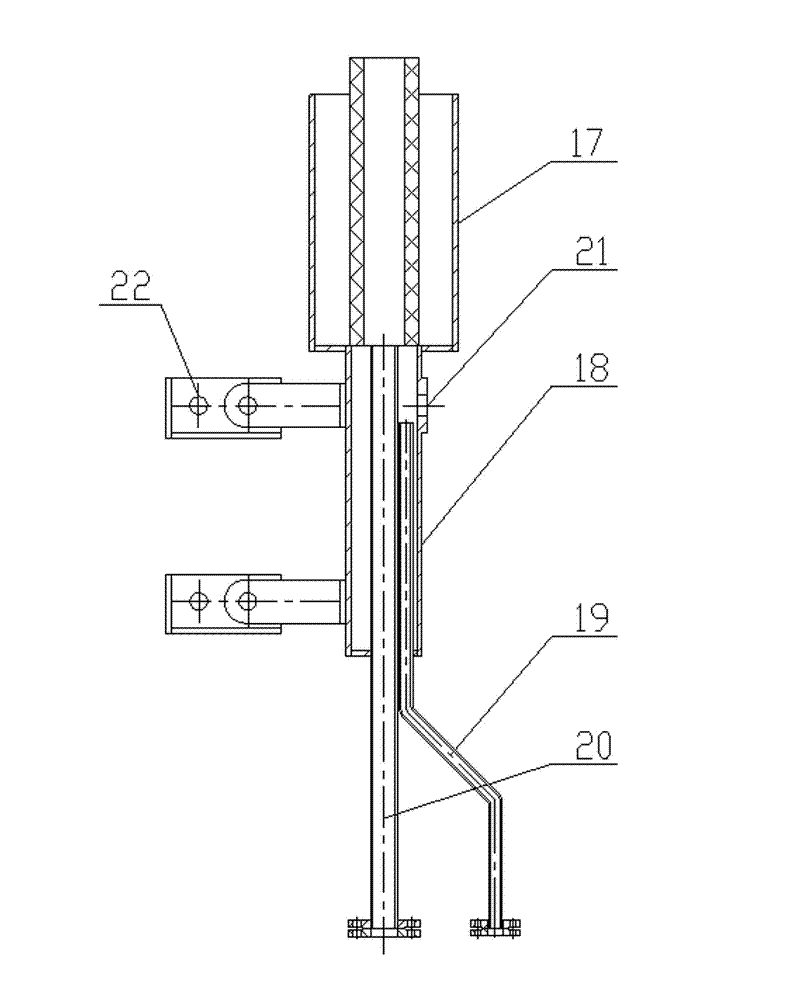

[0019] like Figure 1-3 As shown, the novel blast furnace gas release and automatic ignition system of the present invention includes a blast furnace gas main network 1, and the blast furnace gas main network 1 communicates with the storage tank 5 of the gas distributor 4, and the gas distributor 4 also includes three groups Gas valve 6, the three groups of gas valves 6 are respectively connected to three high-altitude accompanying burners 7, and the high-altitude accompanying burners 7 are fixed on the upper part of the main burner 8 through the fixing bracket 22, and the top of the main burner 8 is connected to the fire The detection device 11, the fire detection device 11 is connected to the blast furnace gas release management system 3, the bottom of the main burner 8 is connected to the release pipe 9, and the release pipe 9 is connected to the blast furnace gas main network 1, and the blast furnace gas main network 1 A pneumatic quick-cut valve 2 is installed, the pneuma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com