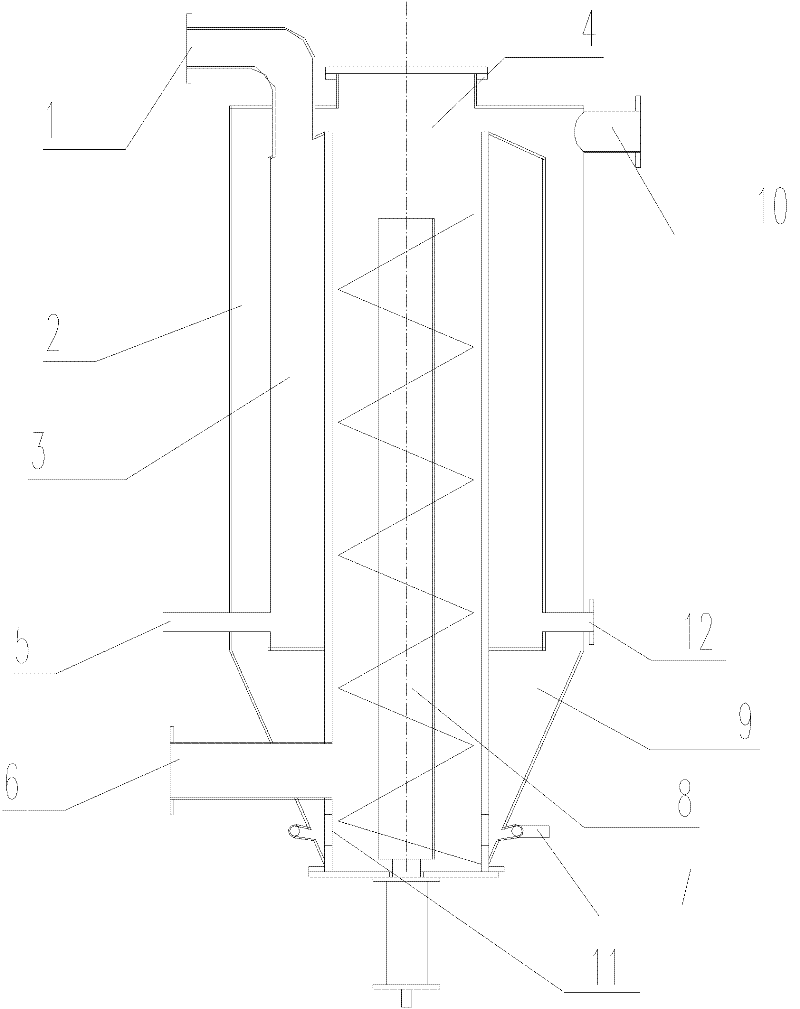

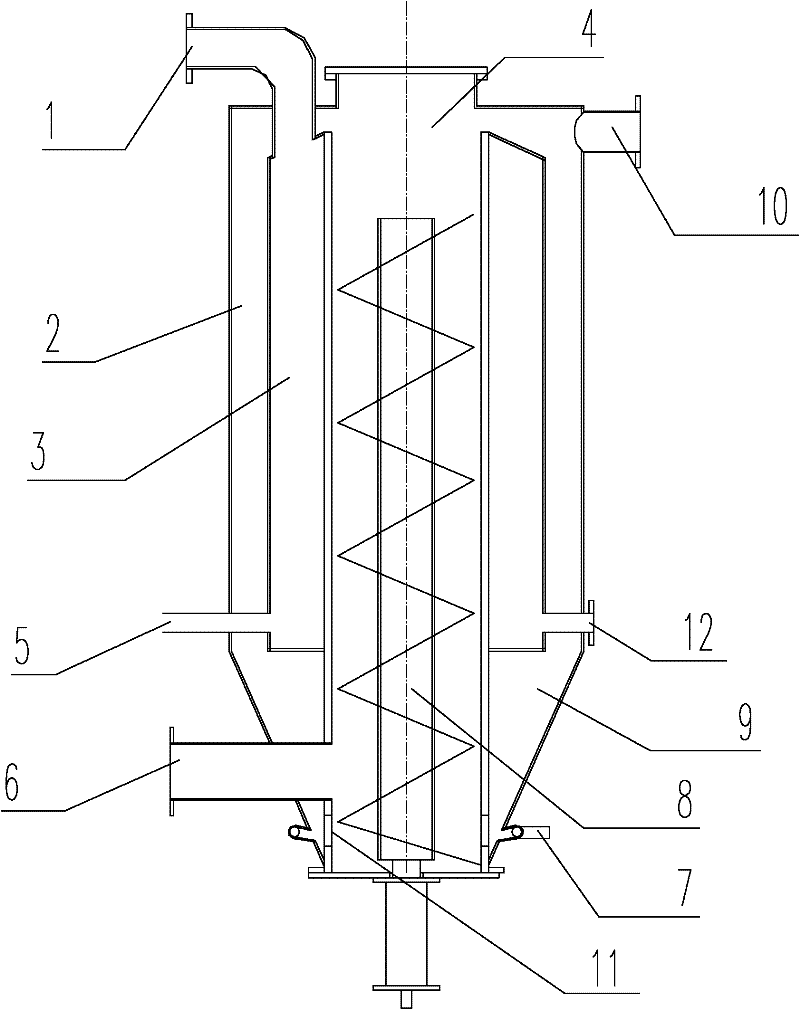

Internal circulation external heating type gasification device

A gasification device, external heating technology, applied in the field of internal circulation and external heating gasification devices, can solve the problems of incomplete and continuous movement of gasification raw materials, low conversion efficiency of residual carbon, and short residence time, etc., to achieve improved Heat and mass transfer efficiency and gasification rate, heat loss is small, and the effect of improving gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] The experimental raw material is pine sawdust from a furniture factory, which is processed into a powder with a particle size of less than 250 μm by a self-made crusher, and then cracked in the gasification device.

[0031] After the raw material is cracked, the total gas production is 1.53Nm 3 / kg. The gaseous products mainly include H 2 , CO, CH 4 、C 2 h 4 、C 2 h 6 and CO 2 etc., the respective contents are 42.8%, 22.5%, 5.7%, 0.8%, 0.06% and 27.2%, the residual oxygen content is 0.3%, and the carbon conversion rate reaches 93.59%.

example 2

[0033] The experimental raw material is urban waste from a certain place, and its main components include kitchen waste, paper, fabric, bamboo wood and plastic. The raw material is processed into particles with a particle size of less than 15mm by a self-made crusher, and the cracking reaction is carried out in the gasification device, and the moisture content of the crushed garbage is 29.5%.

[0034] After the raw material is cracked, the total gas production is 1.12Nm 3 / kg. The gaseous products mainly include H 2 , CO, CH 4 、C 2 h 4 、C 2 h 6 and CO 2 , etc., the respective contents are 44.3%, 21.5%, 5.6%, 0.6%, 0.1% and 26.9%, and the residual oxygen content is 0.3%. Due to the increased residence time, the conversion of carbon reached 90.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com