A kind of processing method containing citric acid solution

A citric acid solution and treatment method technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of high production cost, large amount of waste liquid, small amount of adsorbed citric acid, etc., and reduce the cost of environmental protection treatment , Reduce energy consumption, improve the effect of purity and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Decolorization: after the 1120L obtained after centrifugation, the citric acid clear liquid with a content of 14.2% by weight was passed through the GH-15 carbon column at a flow rate of 1.8 times the column volume / hour, and the carbon column was carried out with 80L of deionized water. Rinse to obtain 1200L of effluent A1, the content of citric acid in the effluent A1 is 13% by weight, the light transmittance of the effluent A1 is 85%, and the temperature during decolorization is 50 ° C;

[0055] (2) adjusting pH: the pH of effluent A1 is adjusted to 2.0 with sodium hydroxide to obtain solution B1;

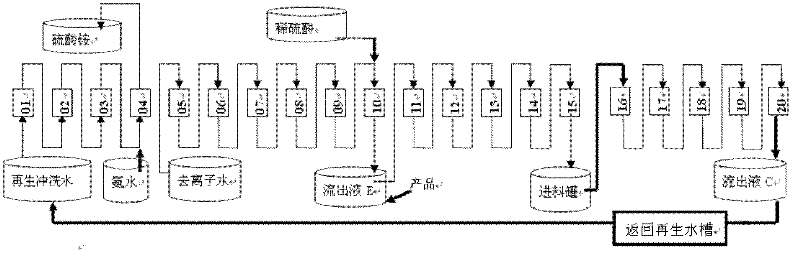

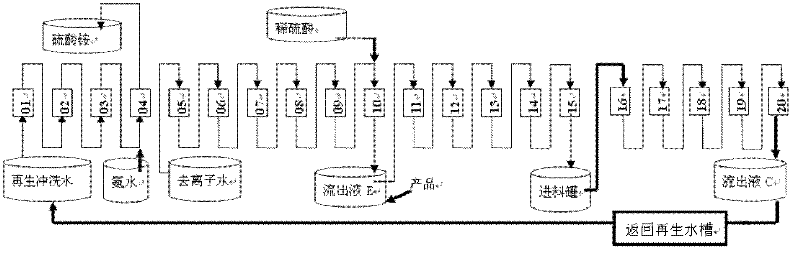

[0056] (3) ion-exchange chromatographic separation: the effluent B1 is introduced into a chromatographic system with a built-in selective separation resin (weakly basic anion-exchange resin SQD815) in a co-current manner for chromatographic separation;

[0057] The operating conditions are, adsorption zone: effluent B1 is introduced from the upper end of the resin colu...

Embodiment 2

[0070] (1) Decolorization: 850L of the citric acid clear liquid obtained after centrifugation with a content of 17.9% by weight is passed through the GH-11 carbon column at a flow rate of 1.5 times the column volume / hour, and the carbon column is carried out with 70L of deionized water. Rinse, obtain the effluent A2 of 920L, the content of citric acid in the effluent A2 is 16.3% by weight, the light transmittance of the effluent A2 is 82%, and the working temperature during decolorization is 55 ℃;

[0071] (2) adjust pH: the pH of effluent A2 is adjusted to 2.5 with sodium hydroxide to obtain solution B2;

[0072] (3) ion-exchange chromatographic separation: the effluent B2 is introduced into a chromatographic system with a built-in selective separation resin (weakly basic anion-exchange resin SQD815) in a co-current manner for chromatographic separation;

[0073] The operating conditions are, adsorption zone: effluent B2 is introduced from the upper end of the resin column gr...

Embodiment 3

[0079] (1) Decolorization: 1150L of the citric acid clear liquid obtained after centrifugation with a content of 16.6 wt % was passed through the GH-15 carbon column at a flow rate of 2.0 times the column volume / hour, and the carbon column was carried out with 100L of deionized water. Rinse, obtain the effluent A3 of 1250L, the content of citric acid in the effluent A3 is 15.1% by weight, the light transmittance of the effluent A3 is 83%, and the working temperature during decolorization is 40 ℃;

[0080] (2) adjust pH: the pH of effluent A3 is adjusted to 3.0 with sodium hydroxide to obtain solution B3;

[0081] (3) ion-exchange chromatographic separation: the effluent B3 is introduced into the chromatographic system of the built-in selective separation resin (weakly basic anion-exchange resin SQD816) in a co-current manner to carry out chromatographic separation;

[0082] The operating conditions are, adsorption zone: effluent B3 is introduced from the upper end of the resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com